- Home

- Contact Us

- News & Events

- Awards

- AAEES Awards Criteria

- 40 Under 40 Recognition Program

- Edward J.Cleary Award

- Excellence in Environmental Engineering and Science Education

- Gordon Maskew Fair Award

- Honorary Member

- International Honorary Member

- Ralph and Joe Bales Graber Science Award

- Stanley E. Kappe Award

- Environmental Communications Awards Competition

- Excellence in Environmental Engineering and Science Competition

- The AAEES Chapter Blue Marble Award

- Resources

- AAEES Microcredentials

- Annual Reports

- AAEES Press Releases

- AAEES Website How To VIdeos

- Environmental Engineer and Scientist

- Environmental Engineering Body of Knowledge

- PFAS Resources

- Specialty Examination Guide

- Students and Young Professionals Resources

- Who's Who in Environmental Engineering & Science®

- Leadership Opportunities

- Membership

- Donate

- Jobs

2025 Excellence in Environmental Engineering and Science® Awards Competition Winner

Superior Achievement

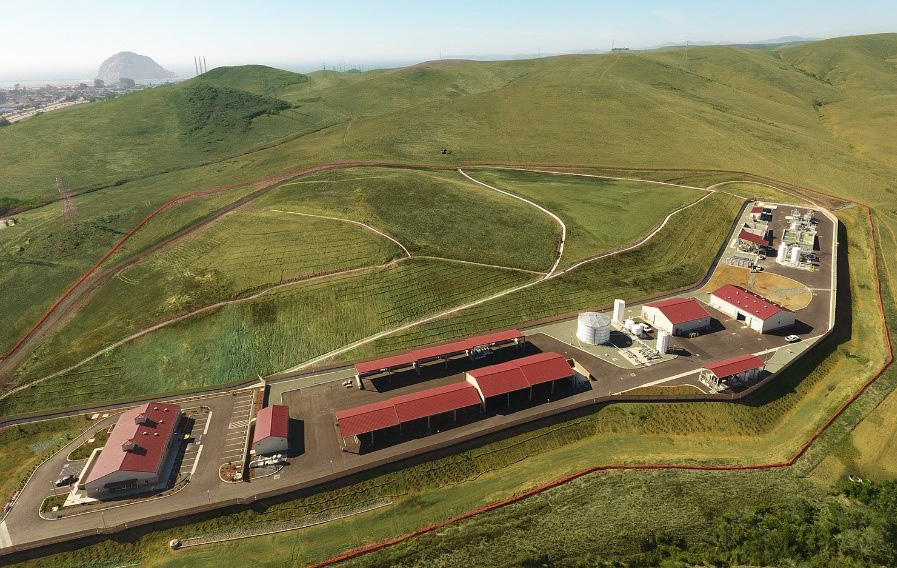

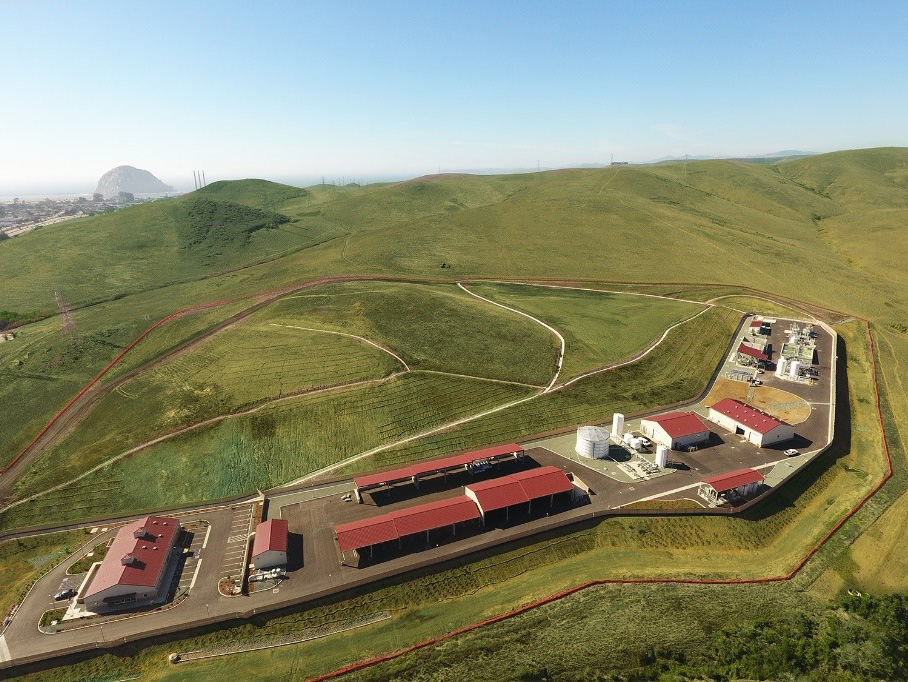

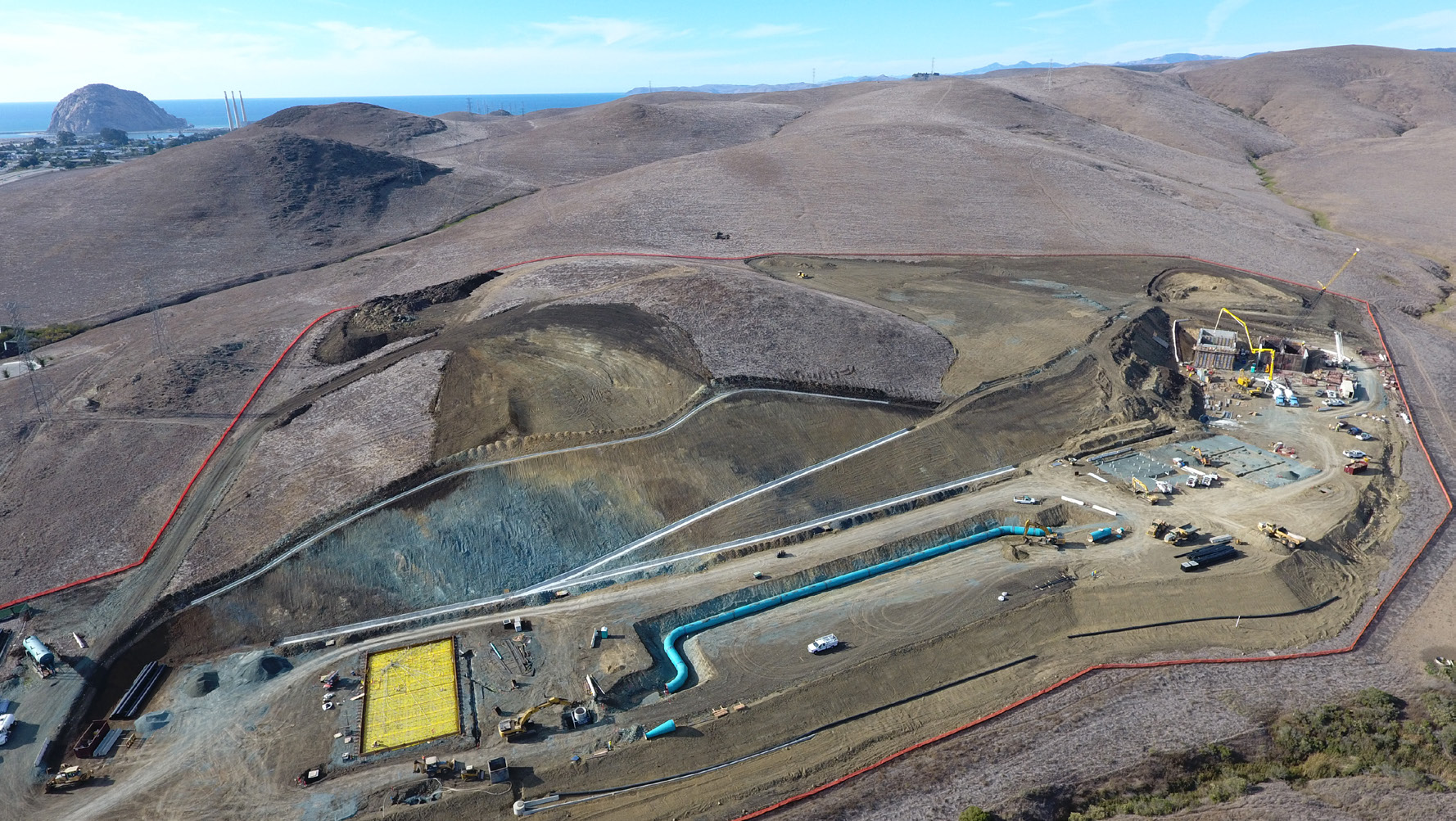

Category Entered: DesignMorro Bay Water Resources CenterEntrant: Black & Veatch Entrant Profile Entrant: BLACK & VEATCH Design-Builder: FILANC BLACK & VEATCH (JOINT VENTURE) Project Owner: CITY OF MORRO BAY, CA Structural Engineer: ASHLEY & VANCE ENGINEERING Owner’s Advisor: CAROLLO ENGINEERS Electrical/I&C Subcontractor: ELECTICRAFT INC. Architect: FRASER SEIPLE ARCHITECTS For the Morro Bay Water Reclamation Facility Design-Build project, the entrant, Black & Veatch, was the design-builder in a 50/50 joint venture with Filanc Construction named Filanc Black & Veatch. Project DescriptionComprehensive, Integrated ApproachThe City of Morro Bay faced multiple challenges: the California Coastal Commission would not renew the permit for their aging 60-year-old wastewater treatment plant (WWTP) because it was located directly on the beach, in a flood zone, placing the coastal environment in jeopardy; their existing WWTP was unable to meet upcoming ocean discharge requirements; and, being dependent on imported water, they needed a new local, sustainable water supply. Overall, Morro Bay had a tight budget as this would bethe largest project the city had ever undertaken. Filanc Black & Veatch (FBV), a joint-venture between Filanc Construction and Black & Veatch delivered a new plant via fixed-price design-build that addressed all of these challenges while producing significantly better water quality than city’s anticipated solution. The new facility treats all of Morro Bay’s wastewater, up to 8.14 million gallons per day (mgd), while producing two separate effluent streams with three different process trains. Normally, the plant’s flow istreated with biological nutrient reduction (BNR) paired with a membrane bio reactor (MBR). This produces water witha tenth of the ammonia and a less than a hundredth of the turbidity than its predecessor. This water is then treated further with reverse- osmosis (RO) followed by ultra-violet advanced oxidation process (UV-AOP), calcite buffering, and free-chlorine disinfection to produce 800,000 gallons per day of highly purified water for indirect potable reuse (IPR) via direct aquifer injection. When the plant sees peak flows exceeding 1.88 mgd, the additional flow is treated through a primary filtration process and blended with MBR effluent for ocean discharge. QualityFBV leveraged the design-build process to produce a highly advanced wastewater treatment plant that met discharge permit requirements from the moment it started up. Less than three months later, when the city was hit with a historic storm, the old plant was flooded under five feet of water and mud, rendering it inoperable. Meanwhile, the new plant continued operations uninterrupted while meeting all discharge requirements. Quality started before the project was awarded, during the fixed-price proposal development. FBV used a series of design charrettes to vet design innovations and engineering alternatives. Forty people, representing of all aspects of the design-build team, were present at the primary charette to provide input. This process compressed what would have been months of discussions into just three days. With the optimum configuration determined upfront, the team was able to focus on refining the quality of the design and itsintegration with future construction. The plant has been in continuous operation as Morro Bay’s sole wastewater treatment plant for two years. In that time, it has reliably produced high-quality effluent, having not once violated its discharge permits. The IPR facilities at the plant have been recognized by the California Department of Drinking Water to exceed their performance requirements. Originality & InnovationThis is the first permitted and operational mainline MBR-IPR plant in California, a technology combination that is expected to soon be replicated by many other cities. Black & Veatch engineers used a series of innovations, creative approaches, and new technology applications to make this possible within the city’s budget. Morro Bay has an unusually high wastewater flow peaking factor. Conventionally, a large equalization basin and upsized plant would be used to handle these flows. A novel approach was developed to solve this problem for $7M less. A 1.88 mgd BNR-MBR treatment process handles normal flows. Peak flows above this are treated through a side-stream primary filtration cloth filter and blended with the MBR effluent to produce net effluent that still meets discharge requirements. The conventional approach for hillside construction would be to flatten the site into tiers held by large retaining walls. Instead,the plant was arranged along the natural contours, so no retaining walls were needed. Over 100,000 cubic yards of soil export was averted, saving another $7M. The plant utilizes the natural topography to propel the flow throughout the treatment processes, eliminating intermediate pumping stations, saving another $3M. For example, there are no transfer pumps between MBR and RO as would be typical. All of this was done while making the area around key facilities relatively flat and ADA accessible for public tours. ComplexityThe city had a complex problem to address. As a relatively small community, they had to undertake the largest project in their history within a tight budget. They needed to construct an entirely new WWTP away from flooding danger; it needed to meet more strict discharge requirements; and it needed to provide a new local water resource. Adding to the complexity, construction started just before March of 2020, and several cultural resources were discovered which took regulators longer to address due to the COVID-19 pandemic. As one of the first IPR plants in California, DDW also needed more time to develop their regulatory approval process. Pandemic market delays and pricing volatility were ever-present. In the middle of construction, a landslide plane was discovered. An innovative solution to bench that material into competent rock was devised. The team worked together to address these challenges while still delivering the project on budget and on-time. Contribution to Social, Public, and Environmental Health and Economic AdvancementThis new plant saved the community from an environmental and economic disaster when the old plant was destroyed in historic flooding less than three months after the new plant was started up. Had the new plant not been online, the city would have had no choice but to discharge untreated wastewater to the sensitive marine environment for months, if not years, while the old plant was being repaired. The new plant provides a remarkable improvement in the quality of ocean discharge effluent with a tenth of the ammonia and a less than a hundredth of the turbidity than its predecessor. The high-quality IPR water produced supplements Morro Bay’s local water supply and reduces their dependence on imported water. The new plant is the first of what will soon be many throughout California. The city has provided tours for thousands of citizens, students, and government and representatives as they prepare for their own transition to more sustainable and resilient wastewater treatment and reuse. Click images to enlarge in separate window. Click here to return to the list of 2025 winners. |