- Home

- Contact Us

- News & Events

- Awards

- AAEES Awards Criteria

- 40 Under 40 Recognition Program

- Edward J.Cleary Award

- Excellence in Environmental Engineering and Science Education

- Gordon Maskew Fair Award

- Honorary Member

- International Honorary Member

- Ralph and Joe Bales Graber Science Award

- Stanley E. Kappe Award

- Environmental Communications Awards Competition

- Excellence in Environmental Engineering and Science Competition

- The AAEES Chapter Blue Marble Award

- Resources

- AAEES Microcredentials

- Annual Reports

- AAEES Press Releases

- AAEES Website How To VIdeos

- Environmental Engineer and Scientist

- Environmental Engineering Body of Knowledge

- PFAS Resources

- Specialty Examination Guide

- Students and Young Professionals Resources

- Who's Who in Environmental Engineering & Science®

- Leadership Opportunities

- Membership

- Donate

- Jobs

2020 Excellence in Environmental Engineering and Science® Awards Competition Winner

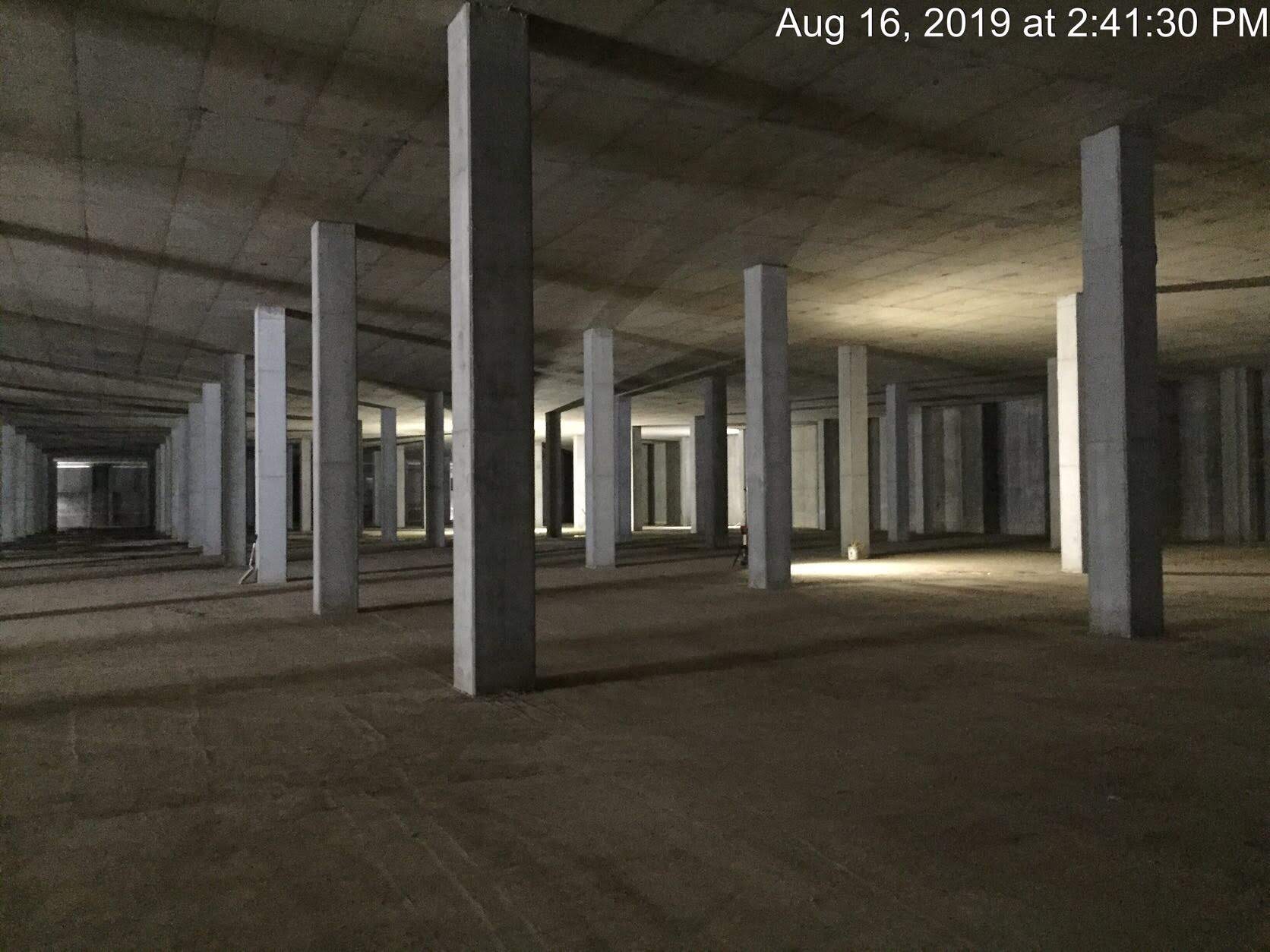

Grand Prize - DesignStormwater and Deicing Capacity ProjectsEntrant: Wessler Engineering Entrant Profile Wessler Engineering is a team of water resources experts who help local committed leaders make sure their water is safe, managed, and future-proof. Wessler Engineering was the Prime Consultant and Lead Designer on the Indianapolis Airport Authority's Stormwater and Deicing Capacity Projects. Wessler provided lead design, construction administration and construction observation. When Wessler was awarded its contract, IAA made it clear this high-profile project was being performed for a client with unrealistic expectations and an impossible schedule. Wessler assembled a team and served as Prime for eighteen partner firms. To achieve the IAA objectives, multiple sites and disciplines were designed simultaneously. Eighteen (18) subconsultants were selected to meet the Indianapolis Airport Authority's minority and diversity goals. Subconsultants provided services in the following areas: structural, electrical, mechanical design and construction administration; FAA and airspace coordination and permitting; environmental and regulatory coordination and permitting; modeling; construction cost estimating; materials testing; hydrologic and hydraulic engineering; geotechnical engineering; and survey. Weekly meetings between IAA, the design team and construction manager determined the attitude and mindset for the entire design and construction effort. Value engineering and construction sequencing were considered paramount and throughout the design phase, ideas were vetted, and decisions made quickly; the design contract was awarded in August 2017 and the first bid documents were issued in February 2018. Project DescriptionIn January 2018, FedEx announced a seven-year, $1.5 billion hub expansion at their Indianapolis facility. In anticipation of this announcement, Indianapolis Airport Authority (IAA) selected Wessler Engineering to deliver major modifications of the Stormwater and Deicing facilities. In concept this project is simple; collect and store stormwater and discharge "clean" water slowly to local streams in compliance with the airport NPDES permit or "contaminated" water to the Indianapolis sanitary system. Existing storm sewers convey airport runoff to large open-air basins located on land adjacent to FedEx needed for their expansion plans. Airspace security, a 150-year old, 400-gravesite cemetery and large-diameter tunnels are not typical issues related to a stormwater facility but were all considerations of this project. The east project: Hanna Basin and Seerley Creek Facility, included two large diameter 750-foot long tunnels under I-70, an enclosed 10-million-gallon storage and junction chamber and 7 mgd pumping station, 95 million gallons of new storage in three reinforced polypropylene geomembrane lined basins and three large pumping stations (a 40 mgd station used to fill the basins upper portion and transfer stored water between basins, a 13 mgd station to pump contaminated water to the municipal collection system and an 8.5 mgd station to pump clean water back to the Seerley Creek Facility for release). A new West Basin, to handle runoff from the west side of the airport, includes another 5-million-gallon lined basin and 7 mgd pump station along with a 24-inch force main under I-70 and nearly 13,400 feet back to the Hanna Basin. Flow and fill sequences are programmed, monitored and managed via real-time SCADA including the potential to automate sluice gates and pumps. The design allows IAA personnel to override the system to manually manage runoff streams based upon weather, basin levels, flow rates and readings obtained from strategically placed TOC analyzers. Much of the design incorporated "tried and true" technologies configured for new objectives. Equipment selection mandated durability in harsh environments and was upsized to address the extreme sizes of this project. Sustainable design goals included segregating runoff streams to provide recycling opportunities if/when it becomes cost-effective. Energy efficiency was another sustainability goal. Peak runoff rates to the Seerley Facility can exceed 170 CFS (110 MGD) and a single storm can create 25 million gallons of runoff. Instead of pumping, the 78-inch pipe from Hanna fills the first 15 feet of the 30-foot deep Seerley basins by gravity with pumps filling the remainder. For many rainfall events, no pumping will be required aside from the discharge to the sanitary collection system. Engineering costs accounted for approximately half a percent of the of total FedEx project budget, yet planning and delivery were considered critical to attain the unrealistic and impossible timeline. IntegratedAir: The IAA deicing runoff basins are miles apart. The Deicing Capacity Projects included a SCADA system for remote monitoring and operation of the system, thereby reducing the number of trips by car and the associated emissions. Water: The runoff streams are segregated and managed separately in order to maximize clean releases to the receiving stream and minimize the volume of contaminated runoff sent to the sanitary sewer system. Land: The basin grading plan minimized spoils. Excavated material was used to build the embankments. No clean fill was sent to a landfill. A soil stockpile was formed for future use at the airport. QualityIAA plays a large role supporting central Indiana socially, environmentally and economically. Early in the design phase, a Sustainability Charette was held with the stated purpose being "to holistically identify priorities, generate sustainability ideas and assess their feasibility based on the specific challenges/opportunities for the project". Throughout the design and into construction, aspects of this project were vetted with IAA staff and ultimately decisions were made which considered schedule and perception more than simply cost. Significant thought went into how this system would be operated both at inception and into the future when regulations might change. Original and Innovation

Complexity

Contribution to Social or Economic AdvancementAt its core, this is an environmental engineering project with sustainability a key tenant. As temperatures dip below freezing, aircraft deicing fluid (ADF) is applied to remove and/or prevent ice from forming on planes. This project was designed to protect the downstream receiving streams and groundwater.

Click images to enlarge in separate window. Click here to return to the list of 2020 winners. |