- Home

- Contact Us

- News & Events

- Awards

- AAEES Awards Criteria

- 40 Under 40 Recognition Program

- Edward J.Cleary Award

- Excellence in Environmental Engineering and Science Education

- Gordon Maskew Fair Award

- Honorary Member

- International Honorary Member

- Ralph and Joe Bales Graber Science Award

- Stanley E. Kappe Award

- Environmental Communications Awards Competition

- Excellence in Environmental Engineering and Science Competition

- The AAEES Chapter Blue Marble Award

- Resources

- AAEES Microcredentials

- Annual Reports

- AAEES Press Releases

- AAEES Website How To VIdeos

- Environmental Engineer and Scientist

- Environmental Engineering Body of Knowledge

- PFAS Resources

- Specialty Examination Guide

- Students and Young Professionals Resources

- Who's Who in Environmental Engineering & Science®

- Leadership Opportunities

- Membership

- Donate

- Jobs

2018 Excellence in Environmental Engineering and Science® Awards Competition Winner

Honor Award - Industrial Waste PracticeFactoria Recycling and Transfer StationEntrant: HDR Entrant Profile HDR's Role in the Project: Lead design firm. HDR provided environmental, permitting, architectural and engineering design, publicinvolvement and construction-related services for this major transfer station replacement. Alarge number of HDR staff, 197 people from multiple offices, worked on the $52 million construction project. Role of Other Consultants

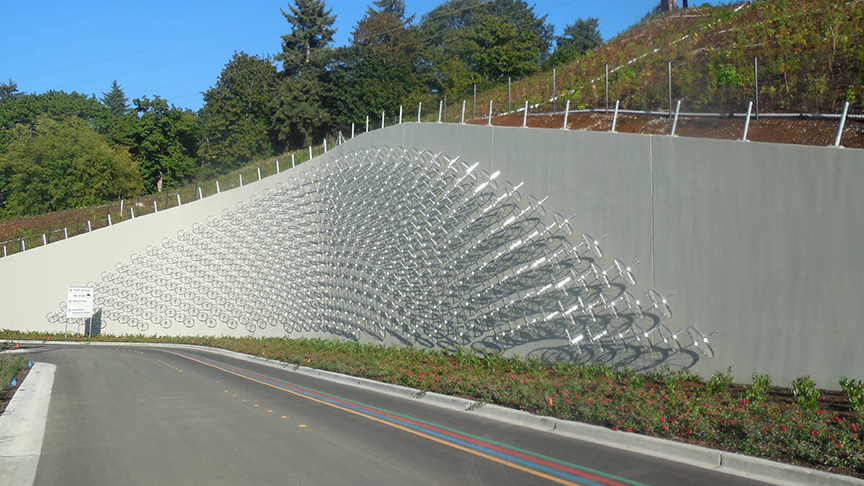

Project DescriptionTwenty-five years ago, King County Solid Waste Division (KCSWD) knew it needed a new transfer station. An initial plan failed to accommodate future growth or recycling. A second design sought to construct in a more visible part of the property, causing the City of Bellevue to balk. By purchasing adjacent property and using an innovative construction approach, the HDR team presented a third design with a larger facility at a lower elevation - which proved a charm. The state-of-the-art, nearly 80,000-square-foot facility is capable of handling 225,000 tons of garbage, recycling, yard waste and household hazardous waste (HHW) annually. With Factoria Recycling and Transfer Station offering recycling services for major appliances, yard waste, scrap metal, commingled recyclables and textiles, customers have more recycling and disposal options than ever. Comprehensive, Integrated ApproachDesigned to meet LEED Gold criteria, Factoria is a model for sustainable transfer station design. Featuring translucent skylights and window panels to allow natural light into the building and lights automatically dimming lights, the facility uses 40 percent less electricity than similar facilities. In addition, the rainwater catchment system is anticipated to save approximately 1.3 million gallons of potable water a year, while the team diverted 95 percent of construction waste from landfilldisposal. QualityAfter separating recycling and non-refuse items, the new facility condenses waste with two stationary compacters. The compactor design improves the previous top-loaded system by providing consistent 26-ton loads, eliminating approximately 8 vehicle trips per day. By operating more efficiently, less time, money and fuel is wasted on queuing vehicles. With standard commercial collection trucks averaging about 3.5 miles-per-gallon of gas, it is important they move through the station quickly. The new design allows commercial customers to enter the building, unload waste and exit within 5 minutes. The flexible tipping floor provides 11 self-haul unloading stalls during weekdays. During weekends, when self-haul traffic increases and commercial traffic decreases, tipping floor operations may be orientated to use the commercial tipping area, thereby better serving KCSWD customers. Originality and InnovationKCSWD's first flat-floor transfer station also offers a safer environment, reducing opportunities for workplace injuries in comparison to the previous transfer station design. The flat floor allows space for three days of solid waste emergency storage in case of transfer and disposal disruptions. With Factoria Recycling and Transfer Station handling more than 16 percent of King County's solid waste, closing the existing transfer station during construction was not an option. Throughout the three-year project, services remained uninterrupted and operational despite excavating about 300,000 tons of soil and using a large, temporary retaining wall to support the 80-foot elevation drop between the facilities. The new station is designed with flexibility to adjust to KCSWD's future needs. In fact, the facility's entire operation can be changed if necessary. Five large doors allow flexible traffic flow while extra electrical hookups can incorporate new equipment. With the ease of drop-off, variable traffic flow, improved safety and future flexibility, KCSWD is requiring future transfer stations to be flat-floor designs as well.

Services remained operational despite excavation of about 300,000 tons of soil and use of a large, temporary retaining wall to support an 80 foot elevation drop between the facilities. ComplexityPrevious attempts to modernize the station would have required closing during construction. Through a complex phasing effort - including a 40-foot high, 313-foot-long temporary shoring wall, four traffic patterns and considerable earthwork - the facility remained operational throughout construction. The shoring wall location challenged construction, requiring parking transfer trailers in locations typically used for other activities and a temporary guard rail to maintain safe operations. Further, the wall was constructed at night tolimit operational and customer interruptions, and required dewatering of up to 850-gallons-per-minute and geotechnical monitoring of soldier piles. During construction, the contractor navigated the site's tight clearances, as the temporary wall was approximately 20 feet from the new station. With traffic moving around the site in various patterns depending on construction activities, safety was a constant consideration. KCSWD and the team designed andimplemented additional temporary roads during construction, providing better separation of public and commercial traffic. Even getting materials to the site proved difficult. Due to their excessive size, hauling the new compactors to the site was limited to 2:00-5:00 a.m. on a Monday morning. And because they weigh nearly 200 tons together, routes were limited to heavy-duty haul roads and special permits were acquired. Social and Economic AdvancementWe're committed to improving the efficiency and quality of the services we provide to county residents, and this new transfer station delivers. Injust one example, the new compactors at Factoria improved the efficiency of each trailer hauled from this station, which translates to fewer trucks on the road and reduced climate pollution. Demonstrating the best of sustainable design, the new station uses 40 percent less energy than standard energy-efficient buildings - reducing carbon dioxide emissions by 172 tons annually. Rainwater harvesting will offset more than 1.3 million gallons of potable water use annually while slope changes reduceleachate production and, along with trench drains, prevent contaminated water from reaching the storm drainage system. The new station also includes skylights and translucent panels for naturallighting, and 50,000 drought-resistant, native plants. The project's construction materials - including steel, aluminum, gypsum board, insulation and glazing - contained 33 percent recycled content, and 34 percent were sourced from within 500 miles of the project site. Built to maximize employee safety, the fully contained building uses natural ventilation and a misting system for dust and odor control, which provides cleaner air for employees and energy savings by reducing ventilation equipment usage. Multiple hazardous gas detectors and alarms automatically operate exhaust fans and notify staff if carbon monoxide, nitrogen dioxide or other contaminants are detected. Critical to the community, the building was designed for immediate occupancy following a natural disaster, including earthquakes. A standby diesel engine generator can power most of the facility, allowing the station to operate even after natural disasters. Prior to the new station, customers drove approximately 16 miles one way to properly dispose of recycling, yard waste, tires and appliances. While accepted at the old facility, these materials were mixed with garbage and landfilled - the new station is expected to collected 3,500 tons of recyclable or compostable materials during its first year of operation. ConclusionRepresenting the community's sustainability, the ribbon at the grand opening was not a ribbon at all, but a string of garbage and recyclable materials. Offering more recycling and disposal options than ever - and completed on budget - the new transfer station has been heralded by the community. Click images to enlarge in separate window. Click here to return to the list of 2018 winners. |