- Home

- Contact Us

- News & Events

- Awards

- AAEES Awards Criteria

- 40 Under 40 Recognition Program

- Edward J.Cleary Award

- Excellence in Environmental Engineering and Science Education

- Gordon Maskew Fair Award

- Honorary Member

- International Honorary Member

- Ralph and Joe Bales Graber Science Award

- Stanley E. Kappe Award

- Environmental Communications Awards Competition

- Excellence in Environmental Engineering and Science Competition

- The AAEES Chapter Blue Marble Award

- Resources

- AAEES Microcredentials

- Annual Reports

- AAEES Press Releases

- AAEES Website How To VIdeos

- Environmental Engineer and Scientist

- Environmental Engineering Body of Knowledge

- PFAS Resources

- Specialty Examination Guide

- Students and Young Professionals Resources

- Who's Who in Environmental Engineering & Science®

- Leadership Opportunities

- Membership

- Donate

- Jobs

2018 Excellence in Environmental Engineering and Science® Awards Competition Winner

Grand Prize - University ResearchRemediation of Chlorinated Solvent-Contaminated Groundwater Using Long-Lasting and NZVI-Contained Colloidal Substrates with pH and Hydrogen Sulfide Control Capabilities: Innovative Substrate Development and Mechanism StudiesEntrant: Chih-Ming Kao, P.E., BCEE, and Yih-Terng Sheu Entrant ProfileChih-Ming Kao, Ph.D., P.E., DEE, P.H., CGWP, D.WRE, F.ASCE, F.AAAS, F.EWRI, F.EASA, F.IWA, F.IET, F.RSC is a chair professor in the Institute of Environmental Engineering at National Sun Yat-Sen University, Kaohsiung, Taiwan. Prof. Kao was the former Coordinator of Environmental Engineering Program at Ministry of Science and Technology, former President of The Chinese Institute of Environmental Engineering, and former President of The Taiwan Association of Soil and Groundwater Environmental Protection. He received his Ph.D. from North Caroline State University in 1993 and then joined Geophex, Ltd., USA as an environmental consultant in 1993. He became a faculty member of National Sun Yat-Sen University, Taiwan in August 1997. Prof. Kao has published more than 237 peer-reviewed journal papers, 35 books and book chapters, 39 patents, and edited 19 international conference proceedings. Prof. Kao is a Diplomate of the American Academy of Environmental Engineers (DEE) (since 1998), Diplomate of Water Resources Engineer (D.WRE) of the American Academy of Water Resources Engineers, fellow of International Water Association (IWA), fellow of American Society of Civil Engineers (ASCE), fellow of European Academy of Sciences and Arts (EASA), fellow of American Association for the Advancement of Science (AAAS), fellow of Environment and Water Resource Institute (EWRI), fellow of Royal Society of Chemistry (RSC), fellow of Institute of Engineering and Technology (IET), fellow of Hong Kong International Engineering and Technology Association (IETA), fellow of the Chinese Institute of Environmental Engineering (CIENV), a Registered Professional Engineer, a Certified Ground Water Professional, and a Professional Hydrologist in the United States. Prof. Kao has served as the Associate Editor for WEF Journal - Water Environment Research and ASCE Journal - J. of Environmental Engineering and J. of Hazardous, Toxic, and Radioactive Waste, as well as Editor in Chief of J. of Soil and Groundwater Remediation. He also serves as the secretary of ASCE/EWRI Hazardous, Toxic, and Radioactive Waste Engineering Committee and Task Committee Member of ASCE/EWRI's Green Technologies for Sustainable Wastewater Treatment Task Committee, Sustainable Sludge Management Task Committee, Bioenergy and Biofuels Task Committee, Membrane Technology Task Committee, and Climate Change Modeling, Mitigation, and Adaptation Task Committee. In this nominated long-lasting and nano-zerovalent iron (nZVI)-contained colloidal substrates project, as the project principal investigator (PI), he directed research tasks conducted in the Institute of Environmental Engineering, and he also conducted the pilot-scale and full-scale studies using the developed innovative substrates at several chlorinated-solvent contaminated sites for site remediation. He also advised graduate students in the Institute and trained work force at the remediation sites during the research period. Specifically, Prof. Kao's contributions included development of experimental procedures, identification of research directions, integrative analysis and interpretation of the experimental, preparing project reports, publishing scientific papers, promoting technology transfer, patents preparation and application, working with Dr. Sheu continuously on the project, and moving toward new directions (e.g., development of long-lasting biogel substrates). Yih-Terng Sheu, Ph.D., is a lecturer and researcher with the General Education Center at National University of Kaohsiung, Taiwan. In this project, Dr. Sheu worked as a Ph.D. student and then a postdoc under the supervision of Prof. Kao at National Sun Yat-Sen University in 2010.2016. Together they developed innovative long-lasting and nZVI-contained colloidal substrates and successfully applied the products on the remediation of chlorinated-solvent contaminated groundwater sites. Moreover, they also researched the mechanisms of reductive dechlorination of chlorinated solvent, and developed optimal operational procedures to enhance the reductive dechlorination rates of chlorinated solvents, and thus, the site remediation efficiency can be significantly improved. In Aug. 2016, Dr. Sheu joined National University of Kaohsiung. There, he improved the applicability and capabilities of colloidal substrates on site remediation using different mixing techniques and addition of different green components (e.g., gamma poly-glutamic acid, gelation, carboxymethyl cellulose). The modified colloidal substrates are able to overcome the extreme environmental and hydrological problems such as low pH, high heterogeneity, and high hydraulic conductivity. Several patents related to the invented products have been approved by Taiwan Patent Agencies. Dr. Sheu worked with industrial partners to demonstrate and scale up the new treatment systems. The technology was licensed to and being commercialized by several consulting firms including Taiwan Petrochemical Co., Yu-San Environmental Remediation Co., Jei-Po Consultant Co., and Apollo Tech. Co. The technology has received broad attentions from industries, Taiwan EPA, and Ministry of Science and Technology for its potential in the remediation of contaminated soils and groundwater. Together with Prof. Kao, Dr. Sheu also developed a biogel barrier system for heavy metal (e.g., Cr6+) containment and reduction. The new technology can significantly reduce the compliance cost for industries and could have positive impacts on remediation market. Post-doc and Graduate Students at National Sun Yat-Sen University involved in the project:

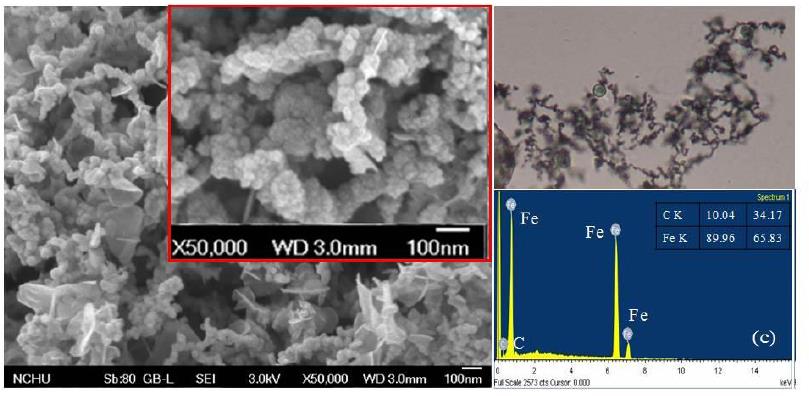

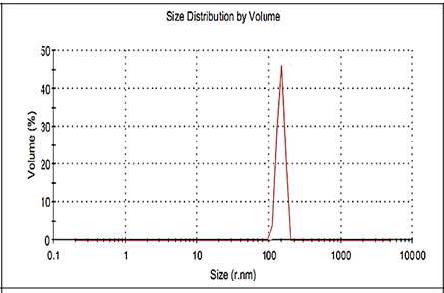

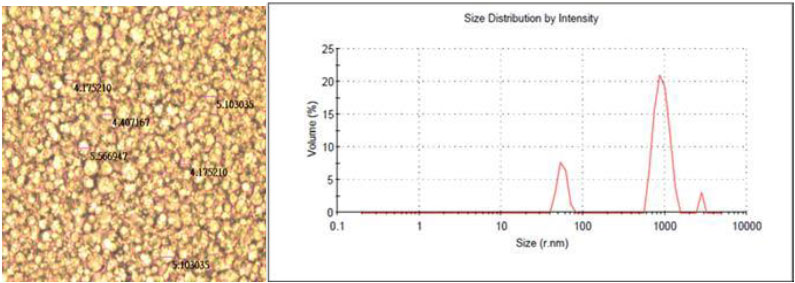

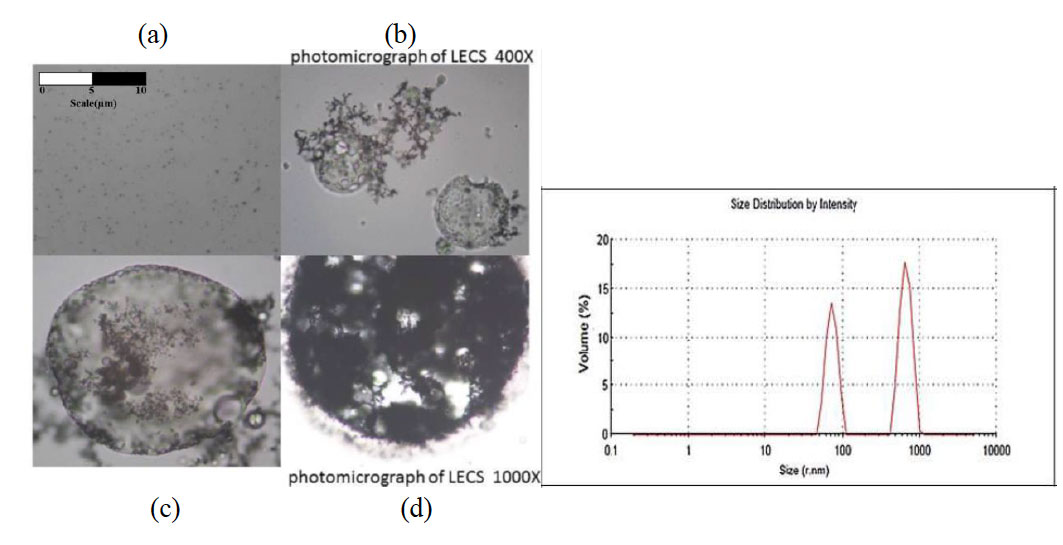

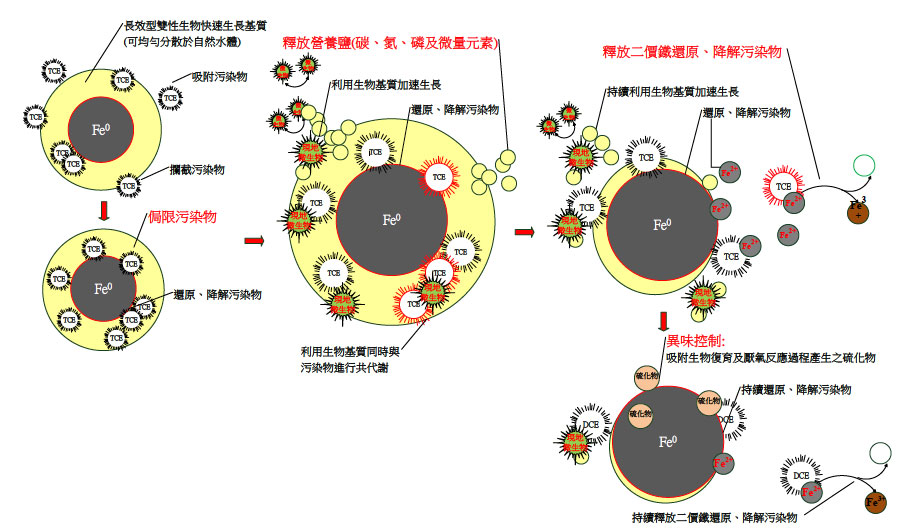

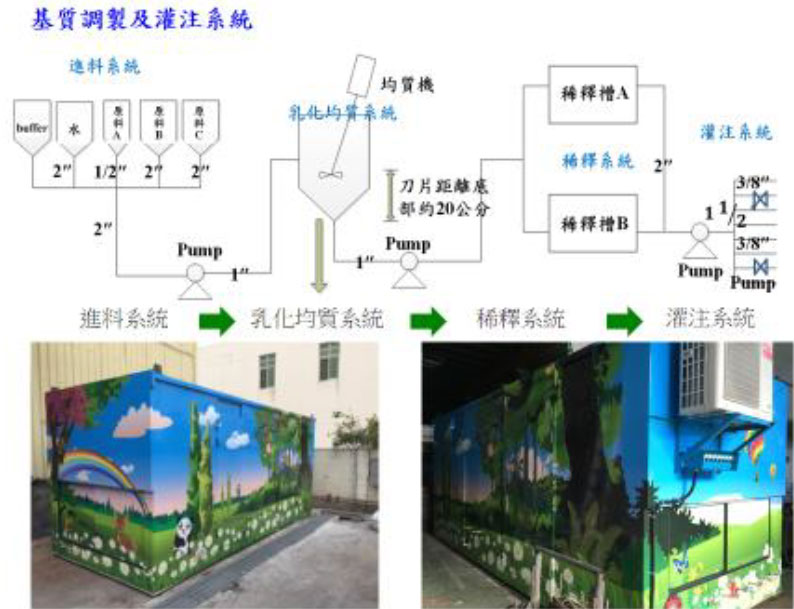

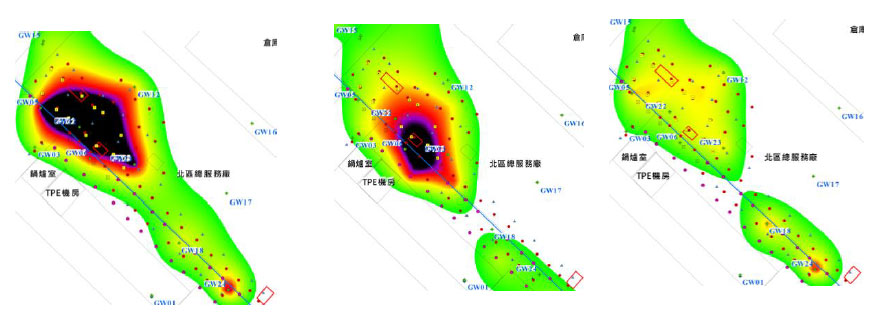

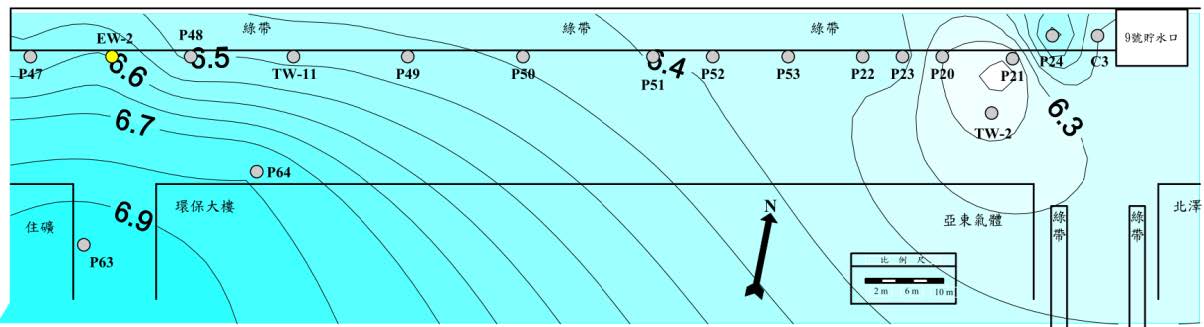

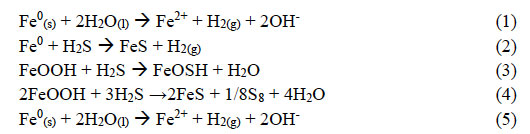

Project DescriptionComplexity of the ProblemChlorinated solvents are some of the most persistent contaminants. At many chlorinated-solvent spill sites, residual amounts of chlorinated solvents persist in a pure liquid phase [commonly referred to as dense, non-aqueous-phase liquids (DNAPLs)] within pore spaces or fractures. The slow dissolution of residual DNAPL results in a contaminated plume of groundwater. The solubilities of chlorinated solvents are typically orders of magnitude greater than typical drinking water standards. Therefore, small volumes of chlorinated solvents released into the subsurface can cause contamination of orders of magnitude higher volumes of groundwater. The free product or residual DNAPLs have sufficient vapor pressure to allow for vaporization into soil gas phase in the vadose zone, resulting in vapor phase plumes of contamination. Using pump-and-treat systems would take many decades to remediate sites contaminated with chlorinated solvents. Since the 1990s, in situ or on-site technologies have been developed to either degrade, remove, or destroy chlorinated contaminant mass in the source zone and downgradient area. Given that it is often very difficult (if not possible) to locate and remove the residual DNAPLs, remediation also needs to focus on preventing further migration of dissolved contamination. Because the source zone DNAPL removal, plume reduction, and plume control need to be operated and maintained for a (long) period of time, it is imperative to develop more cost-effective approaches to remediation and long-term control of contaminated groundwater. In situ reductive dechlorination has become a popular option for remediating chlorinated-solvent spill sites. The bioremediation rates of chlorinated solvents can be enhanced by the subsurface injection of soluble substrates (electron donors), such as lactate and acetate, or immobile substrates, such as bark mulch, compost, and peanut shell. Soluble substrates must be added to the aquifer frequently, which increases capital as well as operation and maintenance costs. Slow-releasing soluble liquid substrates using food-grade edible oils (FEOs) have been developed to release organic substrates, which can support the anaerobic biodegradation of chlorinated solvents and other contaminants. Despite these techniques, very limited solutions have been provided on the following challenges encountered during the in situ reductive dechlorination: (1) decreased pH due to the anaerobic biodegradation of injected primary substrates; (2) production of hydrogen sulfide due to the occurrence of sulfate reduction processes, which causes the odor and toxicity problems; (3) frequent injection of soluble substrates causes the increased operation and maintenance cost; (4) lower hydrogen production efficiency results in reduced reductive dechlorination rates; (5) lacks of appropriate dechlorinating bacteria causing the accumulation of biodegradation byproducts; and (6) non-treatment or containment of DNAPL that causes the continuous release of dissolved chlorinated compounds. Therefore, complete contaminant removal, compliance with the regulatory standards, and achievement of the remediation goals in soil and groundwater remain technically challenging at many polluted sites. Demonstration of a Comprehensive and Integrated ApproachSince 2008, the US Environmental Protection Agency (EPA) has encouraged the application of green remediation technologies for site cleanup. Under the green remediation concept, in situ, passive, and biological technologies meet the requirements for green remediation, and should be applied for contaminated groundwater remediation. The installation of permeable reactive barriers (PRBs) within aquifers is a cost-effective approach for aquifer remediation. In this research project, we developed innovative long-lasting and nZVI-contained colloidal substrates. After investigating the characteristics of the developed substrates via bench- and pilot-scale tests, we injected them into the subsurface polluted zone to create a biological barrier around the injection zone with TCE being dechlorinated inside the barrier. This could contain the TCE plume and prevent its further migration. We then determined the functions, kinetics, and mechanisms of reductive dechlorination of chlorinated solvent, developed the framework for site remediation and optimal operational procedures to enhance the reductive dechlorination rates of chlorinated solvents. We then modified the colloidal substrates the remediation of different contaminated sites with varied environmental and hydrological conditions. We also disseminated our findings to promote the applications of the developed technology. This study found that a series of chemical reactions and mechanisms that in tandem could overcome the drawbacks of traditional reductive dechlorination processes associated with other commonly used substrates (e.g., cane molasses, emulsified substrate alone, lactate and sugar substrates). This bioremediation system meets all the aforementioned challenges (see above for details). The technology developed in this study is a cost-effective biological and passive technology, meets the requirements of the green remediation (in situ, passive, and biological concept), reduces the carbon emissions during the process of site remediation, and thus, is a cutting-edge and cleaner remediation technology. Quality and Importance of This ResearchRemediation of pollutants from different media is very important but often costly. This study developed a new treatment platform that uses innovative long-lasting and nZVI-contained colloidal substrates for reductive removal of chlorinated solvents and plume control from soil and groundwater media. The cumulative work has resulted in publications in peer-reviewed journals (40 papers), presentations in conferences (45) and technique reports (22) for technology transfer. The technology has been commercialized by several consulting firms, including Taiwan Petrochemical Co., Yu-San Environmental Remediation Co., Jei-Po Consultant Co., and Apollo Tech. Co. The technology has received broad attentions from industries, Taiwan EPA, and Ministry of Science and Technology for its potential in the remediation of contaminated soils and groundwater. The long-lasting nZVI-contained emulsified colloidal substrate (LNECS) has been produced by our research team for continuous carbon and nZVI release to remediate chlorinated-solvent contaminated groundwater under anaerobic and dechlorinating conditions. The produced LNECS contained nZVI, vegetable oil, two different surfactants, and mineral nutrients. The LNECS formed a stable oil-in-water emulsion with uniformly small droplets (nano to micro scale). The emulsified solution served as the dispensing agent and nZVI particles could distribute in the emulsion evenly without precipitation and aggregation. The addition of LNECS can create anaerobic conditions in the subsurface after injection. Thus, LNECS can be applied to enhance the in situ reductive dechlorination of chlorinated compounds. The released nZVI could also degrade chlorinated compounds via chemical reduction mechanism. The H2 produced by nZVI reduction could also enhance the anaerobic chlorinated compound dechlorination. Therefore, the application of LNECS would result in a more complete and efficient chlorinated compound removal compared to the injection of carbon substrate alone. The released nZVI from LNECS would also react with sulfide and produce iron sulfide, thus preventing the odor and acidification problems due to the hydrogen sulfide and sulfuric acid caused by the injection of pure carbon substrates, e.g., emulsified substrate. Originality and InnovationAn emulsification process has been applied to reduce the solubility and globule diameter of edible oils. The anaerobic biodegradation of emulsified edible oils produces significant amounts of organic acids (or fatty acids), which causes a significant drop of groundwater pH, inhibiting the microbial dechlorination processes. If the local groundwater contains high concentrations of sulfate, the injection of primary substrates may also enhance the sulfate reduction process and produce abundant hydrogen sulfide (H2S), which causes an odor problem and reduces groundwater quality. Thus, appropriate pH control to maintain neutral pH conditions and the inhibition of H2S production for odor control need to be considered when planning biobarrier system construction. Moreover, biodegradation of chlorinated solvents under anaerobic conditions proceeds by reductive dechlorination might result in the production of more toxic and less biodegradable daughter products such as vinyl chloride (VC). The accumulation of VC during the remediation process often cause a significant environmental problem. The LNECS was developed for continuous carbon and nZVI supplement for the enhancement of reductive dechlorination of chlorinated solvents. Compared to other substrates, using LNECS to enhance the reductive dechlorination of chlorinated solvents has the following advantages: (1) it could be used to provide carbon sources (electron donors) and nZVI for a long period of time with high total organic carbon concentrations; (2) it could create anaerobic conditions and result in the reductive dechlorination and chemical reduction of chlorinated solvents; (3) the released nZVI from LNECS could produce hydroxide ion (Eq. 1) and the neutral pH could be maintained; (4) the released Fe2+ from nZVI could produce iron sulfide, and thus minimize the odor problems (Eq. 2-4); (5) the released nZVI could react with the less biodegradable daughter products (e.g., VC), and thus, prevent the byproduct accumulation problem; (6) the HH2 produced by nZVI reduction could also enhance the anaerobic chlorinated compound dechlorination (Eq. 2 and 5); and (7) emulsified oil serves as a good dispersing agent, which prevents the coagulation of the nZVI particles and extend the life of nZVI.

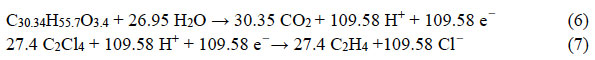

The main component of the LNECS is soybean oil, which serves as the primary substrate during the reductive dechlorination of chlorinated compounds. Each liter of LNECS contains 278 g of linoleic acid, 244 g of leic acid, 33 g of palmitic acid, and 19 g of stearic acid, and thus, each liter of LNECS has 0.99 mole of linoleic acid, 0.51 mole of oleic acid (30%), 0.13 mole of palmitic acid, and 0.07 mole of stearic acid. Therefore, each LNECS contains 30.34 mole of C, 55.7 mole of H, and 3.4 mole of O. If PCE is used as the target compound, during the reductive dechlorination of PCE with the supplement of LNECS, PCE and LNECS serves as the electron acceptor and electron donor, respectively. The reactions are as follows:

Thus, each liter of LNECS produces 109.58 mole of H+, which can dechlorinate 27.40 mole (about 4.54 kg) of PCE to ethene. Injection of developed nZVI-contained colloidal substrates into the subsurface polluted zone can create a biological barrier around the injection zone and result in the chlorinated compound dechlorination inside the barrier. This can contain the plume and prevent its further migration for downgradient receptor protection. Therefore, the environmental risks in the polluted or downgradient zones due to the solvent contamination can be decreased. The bioremediation system, which is a cost-effective biological and passive technology, meets the requirements of the green remediation technology, and the carbon emission during the process of site remediation can be also reduced. Thus, the proposed system would be a cleaner remediation technology. Project Contributions and Broader ImpactsThrough more than 15 years research, Drs. Kao and Sheu have made significant progresses to solve the aforementioned problems and overcome the obstacles of in situ anaerobic bioremediation of chlorinated-solvent contaminated sites. They have developed a series of innovative technologies and made the following distinguished contributions:

Drs. Kao and Sheu systematically investigated the feasibility, applicability, and effects of LNECS on site remediation. Application of LNECS for site remediation meets the concepts of resource recycling, sustainable development, and zero waste/zero discharge. The project advanced fundamentals of how to design and produce different innovative substrates with capabilities of pH control, odor control, long-lasting, slow carbon and nZVI release, and enhancing both biological and chemical reduction processes for site remediation. Results of their studies have direct transferability for people to develop new green remediation processes, and the invented LNECS can be used as a key component of the bioremediation technology for the remediation and pollution control of chlorinated-solvent contaminated sites, which will contribute to reduction of public health risk, revitalization of the contaminated sites with low cost, promotion of economic growth, and development of sustainable society. Click images to enlarge in separate window. Click here to return to the list of 2018 winners. |