- Home

- Contact Us

- News & Events

- Awards

- AAEES Awards Criteria

- 40 Under 40 Recognition Program

- Edward J.Cleary Award

- Excellence in Environmental Engineering and Science Education

- Gordon Maskew Fair Award

- Honorary Member

- International Honorary Member

- Ralph and Joe Bales Graber Science Award

- Stanley E. Kappe Award

- Environmental Communications Awards Competition

- Excellence in Environmental Engineering and Science Competition

- The AAEES Chapter Blue Marble Award

- Resources

- AAEES Microcredentials

- Annual Reports

- AAEES Press Releases

- AAEES Website How To VIdeos

- Environmental Engineer and Scientist

- Environmental Engineering Body of Knowledge

- PFAS Resources

- Specialty Examination Guide

- Students and Young Professionals Resources

- Who's Who in Environmental Engineering & Science®

- Leadership Opportunities

- Membership

- Donate

- Jobs

2018 Excellence in Environmental Engineering and Science® Awards Competition Winner

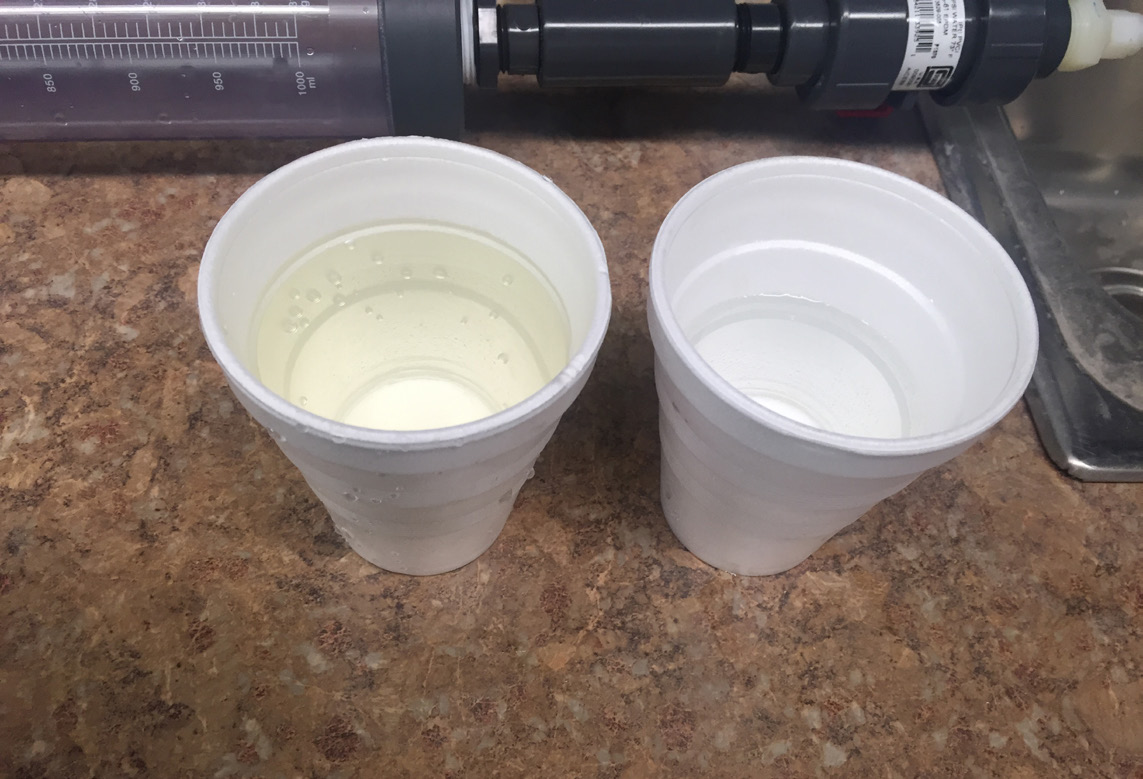

Grand Prize - Small FirmsFlorissant Water & Sanitation District Drinking Water Treatment Improvements ProjectEntrant: AquaWorks DBO, Inc. Entrant Profile AquaWorks DBO is a design/build/operate firm dedicated to providing top-quality municipal water and wastewater treatment facilities. Its primary focus is engineering and installing cost-effective treatment systems that allow its clients to maintain long-term compliance with applicable environmental regulations. AquaWorks DBO caters exclusively to small systems, generally those that treat between 10,000 GPD and 400,000 GPD of potable water and/or wastewater. The majority of its projects have a construction budget of $300,000 to $4,000,000. AquaWorks DBO can provide a wide range of services depending upon the specific needs of the client, from small engineering evaluations up to complete turnkey systems. The Florissant Water & Sanitation District Drinking Water Treatment Improvement Project was completed using the design/bid/build process. AquaWorks DBO was the engineer of record responsible for the environmental engineering design of the project. It was also responsible for all planning, preliminary engineering reporting, and fund/grant acquisitions. Other stakeholders for the project include the Florissant Water & Sanitation District. The district is located in unincorporated Teller County, Colorado, and provides potable water and wastewater service to 250 residents. It is governed by a five-member board of directors elected by the service area. The contractor selected for the project was Dan's Custom Construction of Brighton, Colorado. AquaWorks DBO could not have completed the project without the endless contributions of the district's staff and board of directors and the members of the contracting team. Project DescriptionIntroduction and Problem StatementThe Florissant Water and Sanitation District, located 45 minutes west of Colorado Springs, Colorado, provides municipal water and wastewater service to about 250 residents. The district's drinking water treatment plant faced significant challenges and was under an enforcement order by the Colorado Department of Public Health and Environment to resolve several issues, including conforming with the surface water treatment rule and providing additional disinfection capabilities. Other issues that the district faced included managing iron and manganese loading, as well as resolving significant financial problems prohibiting the district from affording the necessary improvements. Prior to AquaWorks' involvement, the water supplied to the service area was extremely undesirable. The water was dark, stained most of that with which it came into contact, and was unpalatable. Most residents did not use the water, instead preferring to use expensive bottled water. As a result, the district was not generating water sales. This adversely impacted the district's budget and what it could afford to do to remedy the problems. AquaWorks was challenged with engineering and implementing a solution that would meet the surface water treatment rule, make the water desirable for the community to consume again, and increase disinfection capabilities - without the district having the ability to pay for any of it. ComplexitySeveral factors compounded the district's problem, with the most significant one being the inability to pay for the improve- ments. The district was consistently losing money each month and was unable to meet its ongoing obligations. Technical problems existed as well. The iron and manganese that entered the treat- ment system spiked during runoff events. Concentrations of iron under normal conditions ranged from 1 to 2 mg/L. However, after heavy rainfalls, the iron entering the system peaked at 10 mg/L. The system did at one time have direct filtration; however, this unit was not maintained. As a result, it rusted and thus was in need of replacement. The existing disinfection system did not provide for the adequate removal of giardia, and no space in the existing facility was available to provide additional contact volume. Finding a cost-effective solution was imperative, as the district did not have the financial reserves needed to fund plant improvements of this magnitude or to cover costly operational expenses. Originality and InnovationAquaWorks worked to engineer an affordable system that today still meets or exceeds design regulations. The most original and innovative component not seen in conventional projects was the implemention of a pretreatment tank that combines three treatment processes in one step. All of the processes do not cost the district anything to operate and maintain with the exception of pumping out and hauling sediment containing high concentrations of iron and manganese every few years. First, three tanks were installed in a serpentine path, creating a high hydraulic retention time of two days and preventing short-circuiting. Raw water with high levels of iron and manganese blends with water that has lower concentrations of iron and manganese. In addition, peaks of iron are reduced from 10 mg/L to as low as 1 mg/L. Second, a cascading aerator was designed to oxidize the iron. The iron is converted from soluable ferrous iron to insoluble ferric iron through the simple mixing of ambient oxygen. Third, insoluble ferric iron settles to the bottom of the tank over a two-day period. These processes do not require the addition of chemicals. Two new direct filtration units were installed at the treatment plant downstream of the pretreatment tanks. These filters operate significantly more efficiently because of the pretreatment tank. Much of the iron that would have had to have been filtered has now already settled in the pretreatment tank, peaks in iron concentration have been eliminated, and soluble iron, which cannot be filtered, has been converted to insoluble iron, which can be removed with filters. Providing additional disinfection capabilities proved to be a challenge. No space was available in the existing facility to provide additional contact volume. Several options were evaluated, and the simplest, most cost-effective solution was implemented: adding 100 feet of 36-inch high-density polyethylene piping to complement an existing 5,000-gallon chlorine contact chamber. Social and Economic AdvancementThe district was tested most significantly by its relationship with the community. The district could not afford to treat water that no one wanted to drink. Residents had difficulty selling their homes because prospective buyers did not want to purchase homes with undesirable water, and real estate values were depressed as a result. The district was consistently running a negative cash flow and was not a candidate for any loans due to its credit risk and its inability to make debt service payments. However, AquaWorks was able to qualify the district for two grants, which covered the entire cost of the project. The district was not responsible for paying for any of the costs. Because it is now selling more water, it can afford to operate the facility and is running in the black each month. Project IntegrationUpgrading the facility improved the following: Water Quality Improvement: Both primary and secondary health standards were met through the implementation of the project. The facility returned to compliance with the implementation of direct filtration. In addition, the taste and odor issues that the district was having were eliminated. The water is now both safe and desirable to drink. Land Protection: Residents were using bottled water instead of consuming the water that the district supplied. Improving the water quality eliminated the use of bottled water, thus eliminating thousands of the water bottles being sent to landfills (only 23% of water bottles are recycled in the United States). Improved Air Quality: The required chlorine residual concentration dropped from almost 4 mg/L to less than 1 mg/L - significantly reducing the amount of chlorine required at the site. Three-quarters of the chemical deliveries to the site were eliminated along with the associated air quality determinants that the delivery vehicles caused. QualityThe project represents a significant upgrade over the previous facility. Residents are enjoying drinking the water, and the district can operate and maintain an efficient facility that was intentionally engineered to require as little involvement as possible. The quality of the finished project will enable the community to maintain effluent compliance throughout the facility's functional lifespan. Click images to enlarge in separate window. Click here to return to the list of 2018 winners. |