- Home

- Contact Us

- News & Events

- Awards

- AAEES Awards Criteria

- 40 Under 40 Recognition Program

- Edward J.Cleary Award

- Excellence in Environmental Engineering and Science Education

- Gordon Maskew Fair Award

- Honorary Member

- International Honorary Member

- Ralph and Joe Bales Graber Science Award

- Stanley E. Kappe Award

- Environmental Communications Awards Competition

- Excellence in Environmental Engineering and Science Competition

- The AAEES Chapter Blue Marble Award

- Resources

- AAEES Microcredentials

- Annual Reports

- AAEES Press Releases

- AAEES Website How To VIdeos

- Environmental Engineer and Scientist

- Environmental Engineering Body of Knowledge

- PFAS Resources

- Specialty Examination Guide

- Students and Young Professionals Resources

- Who's Who in Environmental Engineering & Science®

- Leadership Opportunities

- Membership

- Donate

- Jobs

2018 Excellence in Environmental Engineering and Science® Awards Competition Winner

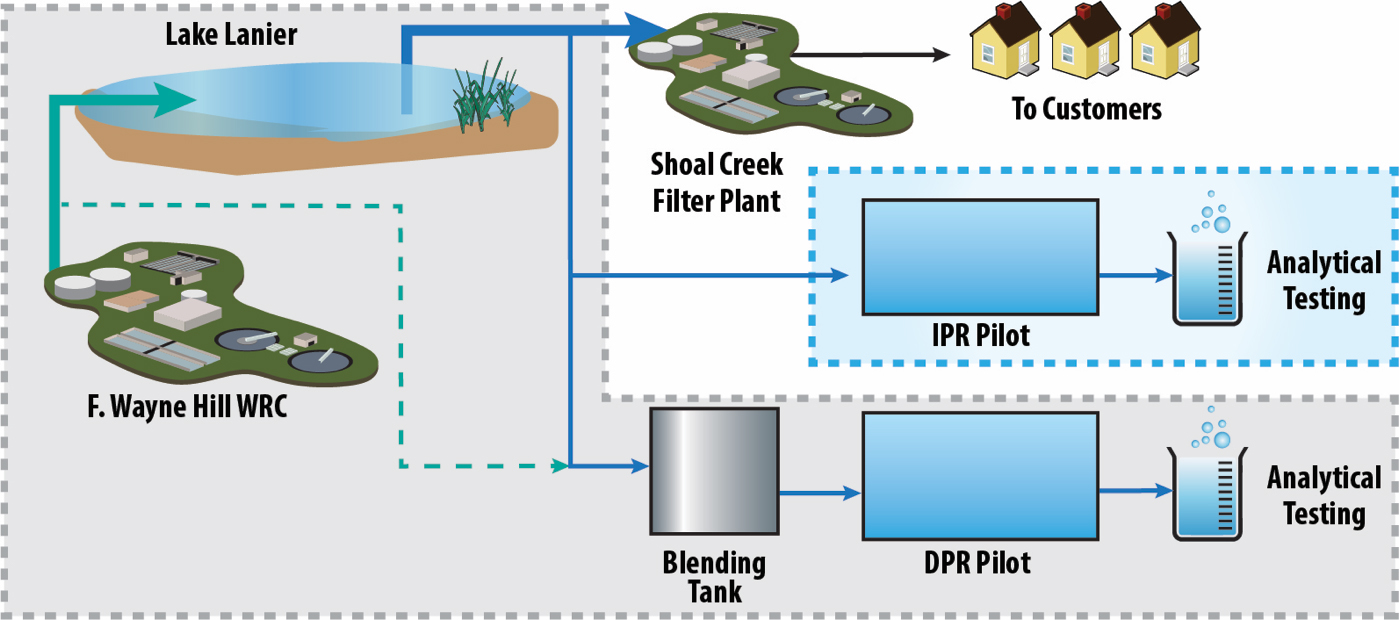

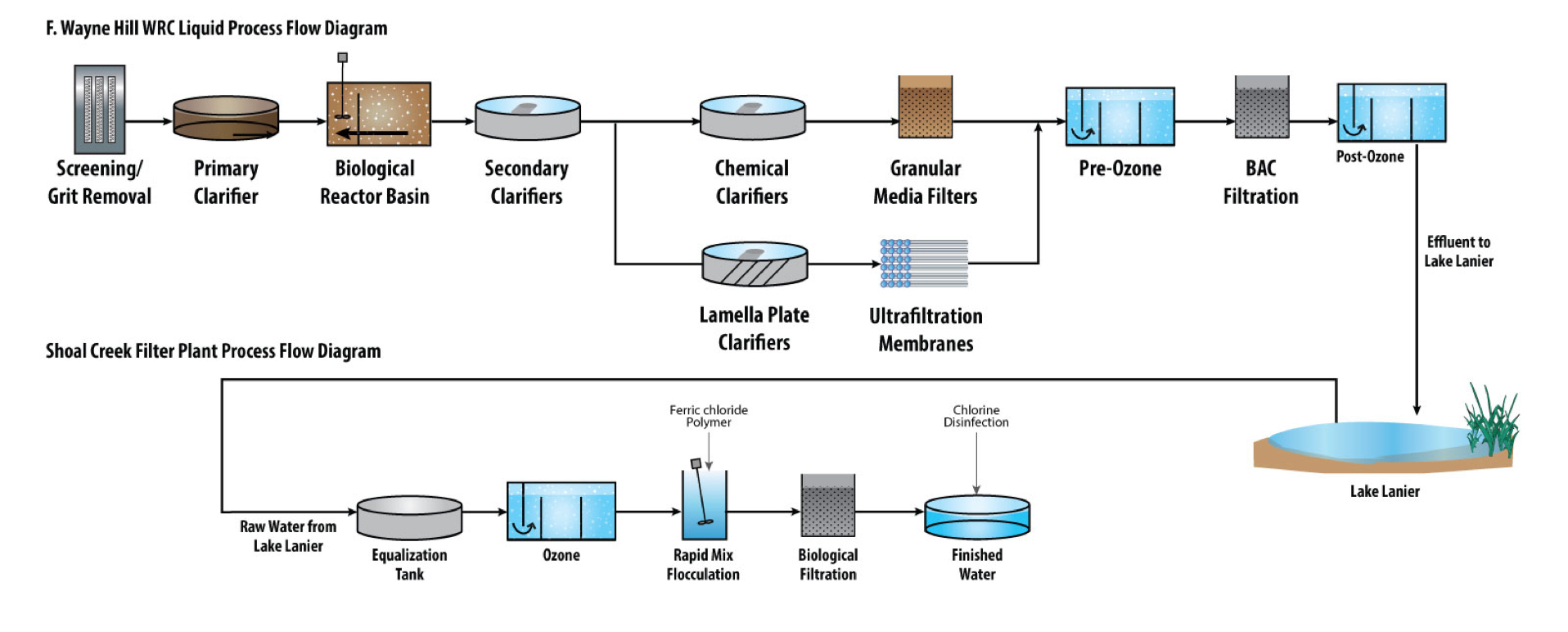

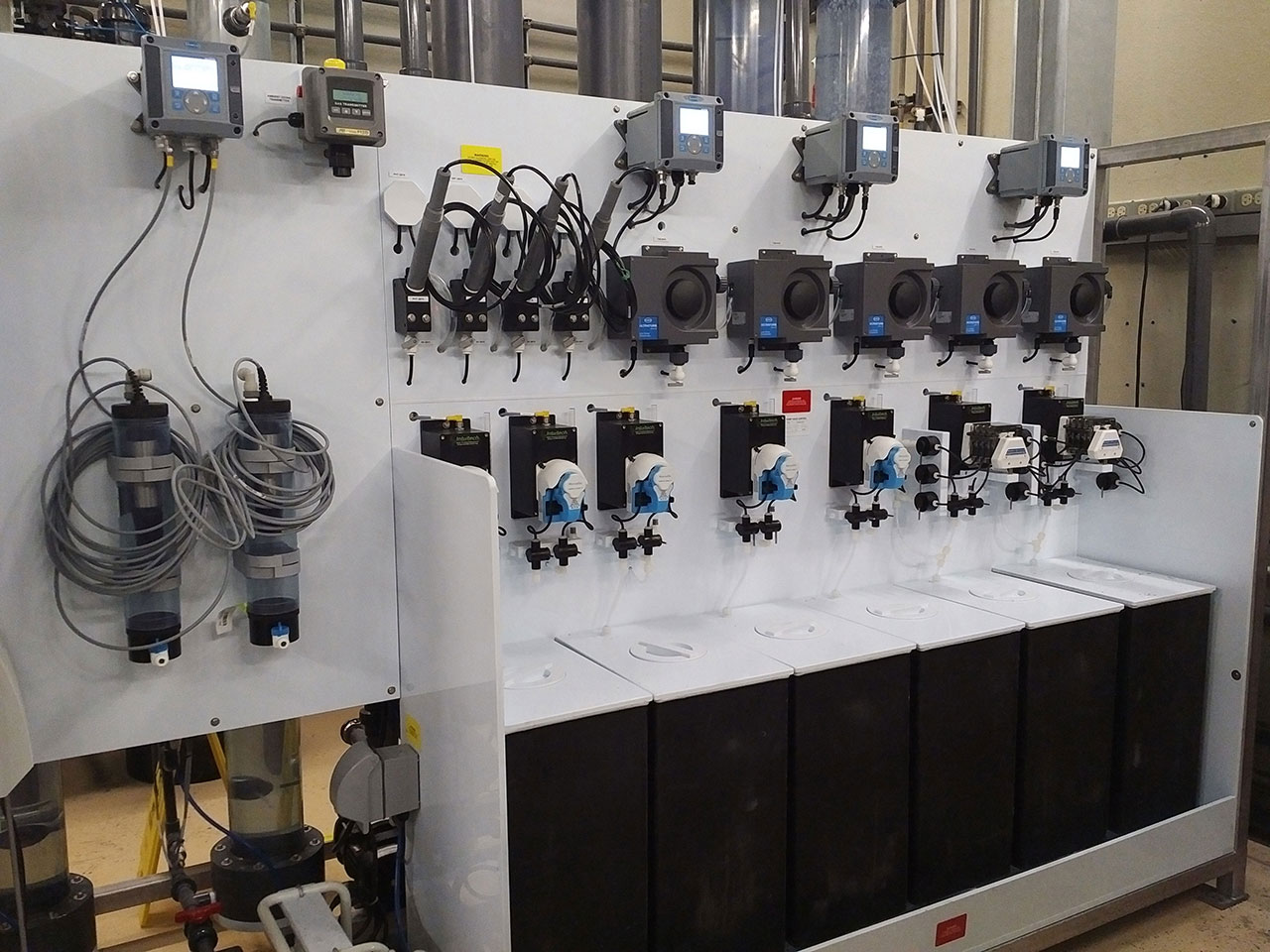

Grand Prize - ResearchDirect Potable Reuse Pilot Testing of Ozone-Biofiltration/Research Project (WE&RF Reuse-15-11)Entrant: Gwinnett County Department of Water Resources, CDM Smith, and Stantec Entrant Profile   Gwinnett County (GC), located in the greater metropolitan Atlanta, Georgia region, is home to more than 900,000 people. Since 2010, GC has been practicing planned indirect potable reuse when the F. Wayne Hill Water Resources Center (FWH WRC), the county's largest water reclamation facility, started returning highly treated reclaimed water to Lake Sidney Lanier, the county's sole source of drinking water supply. The FWH WRC provides wastewater treatment for more than 50 percent of the residents, and has the strictest discharge limits of any facility in the Atlanta area. To fulfill its mission of providing superior water quality at an excellent value, GC Department of Water Resources (DWR) developed a research program to study techniques that enhance current water treatment processes and evaluate future options for water supply. The goal was to evaluate the feasibility of direct potable reuse to achieve high quality drinking water without the use of reverse osmosis. CDM Smith supported GC DWR's principal investigator by assisting with pilot design and operation, developing the research plan, sampling, data management and analysis and summarizing the findings. Additionally, CDM Smith managed five third-party laboratories who performed analytical testing services. Stantec supported GC DWR and CDM Smith as a co-principal investigator involved with project execution, development of a data management platform, result analysis and report writing. CDM Smith provides lasting and integrated solutions in water, environment, transportation, energy and facilities to public and private clients worldwide. The full-service engineering and construction firm is headquartered in Boston, Massachusetts, USA. Project DescriptionPlanned indirect potable reuse (IPR) and direct potable reuse (DPR) projects operated in California and Texas typically rely on treatment processes such as microfiltration/ultrafiltration (MF/UF), reverse osmosis (RO), and ultraviolet (UV) disinfection, with advanced oxidation processes (AOP). While this approach has proven to produce high quality drinking water, the treatment trains are capital and energy intensive, particularly for inland facilities where disposal of RO brine can be cost-prohibitive. Gwinnett County, located in the greater metropolitan area of Atlanta, Georgia, implements planned IPR without RO. The F. Wayne Hill Water Resources Center (FWH WRC) utilizes ultrafiltration, pre-ozone, biologically active carbon (BAC) filtration and post-ozone disinfection to produce high quality water which is returned to Lake Lanier, the County's sole source of drinking water for over 900,000 residents. The drinking water treatment plants, Shoal Creek Filter Plant (SCFP) and Lanier Filter Plant, utilize ozone–biofiltration to produce high quality drinking water. To fulfill its mission of providing superior water service at an excellent value, Gwinnett County Department of Water Resources (GC DWR) conducted a study to evaluate current treatment processes and future options for water supply. One goal was to evaluate the feasibility of using FWH WRC reclaimed water as a direct source of raw water supply for its drinking water facilities. Another objective was to evaluate if blending FWH WRC reclaimed water directly into the raw water would address seasonal operational challenges resulting from changes in lake water quality. This research project was funded by Water Environment & Reuse Foundation (WE&RF), now the Water Research Foundation, as Project 15-11. Pilot testing was completed in June 2017, and GC DWR, CDM Smith and Stantec are preparing the final technical report. Integrated ApproachIndependent pilot testing measured treatment efficacy. Two independent, side-by-side, six-gallon per minute pilot treatment trains were constructed and operated in parallel for nine months. The IPR pilot was fed with lake water only, while the DPR pilot was fed a blend of FWH WRC reclaimed water and lake water. The pilot plants simulated the full–scale drinking water treatment train. Collaboration ensured robust experimental design and analysis. GC DWR, CDM Smith and Stantec collaborated to develop the experimental plan, monitoring regime, and evaluate analytical and operational data real-time during the study. The team developed a cloud-based data management system to allow results from multiple SCADA systems, laboratories and online instruments to be analyzed and compared seamlessly. QualityA rigorous monitoring scheme extensively characterized water quality. Chemical and biological monitoring of 430 analytes produced a robust dataset. Primary and secondary maximum contaminant levels (MCLs) were monitored as well as contaminants of emerging concern, including personal care products and pharmaceuticals, nitrogenous disinfection byproducts, hormones, and perfluorinated compounds. Microbiological parameters were monitored and included: heterotrophic bacteria, total coliform, fecal coliform, coliphage, Enterococcus, Legionella, Cryptosporidium, and Giardia. Additionally, microbial community analyses were conducted. Testing demonstrated benefits of integrating additional alternative water supplies into a portfolio of water resources. The DPR pilot tested four blending ratios - 15, 25, 50, and 100 percent (%) - of advanced treated water from the FWH WRC combined with the raw water from Lake Lanier. The DPR pilot met all of the primary and secondary MCLs evaluated, as well as action levels for emerging contaminants at a blend of 15% FWH WRC effluent and 85% Lake Lanier. All microbiological concentrations were below detection at the DPR pilot effluent for all blend ratios. Originality and InnovationOzone-biofiltration achieved potable quality water in a DPR scenario. This innovative research project demonstrated that ozone-biofiltration, when paired with advanced water reclamation, can provide water of equal or higher quality than current drinking water supplies without the use of RO at a blending ratio of 15% FWH WRC effluent. Challenging source water quality conditions revealed operational benefits of DPR. Process robustness was evaluated during the fall, when Lake Lanier's epilimnion reached the SCFP intake. The warm water with higher organics created operational challenges which were observed in the IPR pilot and full-scale plant, manifesting as increased ozone demand, increased coagulant and flocculant doses and shorter filter run times. Simultaneously, the DPR pilot operating with a 50% blend did not require increased ozone, coagulant or flocculant doses to maintain water quality and filter run times were not shortened. ComplexityThree-phase pilot testing provided solid framework for results. Phase 1 baseline operations were conducted to establish similitude between the two pilots and full scale SCFP. Phase 2 DPR blending evaluated 4 blending ratios over multiple seasons. Phase 3 robustness testing evaluated DPR pilot performance at the 50 percent blend against the IPR pilot operated with 100 percent lake water during challenging seasonal conditions at Lake Lanier. Rigorous testing identified implementation challenges and potential solutions. At the 50% and 100% FWH WRC blends, nitrate and bromate levels slightly exceeded MCLs due to operational modifications for an ongoing project at the FWH WRC. Providing full denitrification to lower nitrate concentrations and optimizing ozone treatment for bromate control could allow higher blend ratios to be implemented. At the 25% FWH WRC effluent blend, cyanide formation was observed during chlorine disinfection and was slightly higher than the primary MCL post-disinfection. Social and Economic AdvancementThe DPR pilot achieved drinking water quality without significantly modifying normal operations. The DPR pilot achieved drinking water quality that met primary MCLs at the 15% blend, without having to modify normal operations at the full-scale plants. Higher blends are possible with modifications at the FWH WRC for nitrate and bromate control. Ozone-biofiltration processes were demonstrated as a viable alternative to RO. This project is pioneering because it investigated a process that does not require RO as part of the DPR treatment train. In cases where total dissolved solids, bromate, and nitrate are low, this approach could reduce capital, operating, and disposal costs associated with use of RO-based treatment trains. This research is of critical importance because it demonstrated the performance of ozone-BAF as a critical element of an alternative treatment process for DPR, reducing cost and eliminating concentrate waste streams. Click images to enlarge in separate window. Click here to return to the list of 2018 winners. |