- Home

- Contact Us

- News & Events

- Awards

- AAEES Awards Criteria

- 40 Under 40 Recognition Program

- Edward J.Cleary Award

- Excellence in Environmental Engineering and Science Education

- Gordon Maskew Fair Award

- Honorary Member

- International Honorary Member

- Ralph and Joe Bales Graber Science Award

- Stanley E. Kappe Award

- Environmental Communications Awards Competition

- Excellence in Environmental Engineering and Science Competition

- The AAEES Chapter Blue Marble Award

- Resources

- AAEES Microcredentials

- Annual Reports

- AAEES Press Releases

- AAEES Website How To VIdeos

- Environmental Engineer and Scientist

- Environmental Engineering Body of Knowledge

- PFAS Resources

- Specialty Examination Guide

- Students and Young Professionals Resources

- Who's Who in Environmental Engineering & Science®

- Leadership Opportunities

- Membership

- Donate

- Jobs

2018 Excellence in Environmental Engineering and Science® Awards Competition Winner

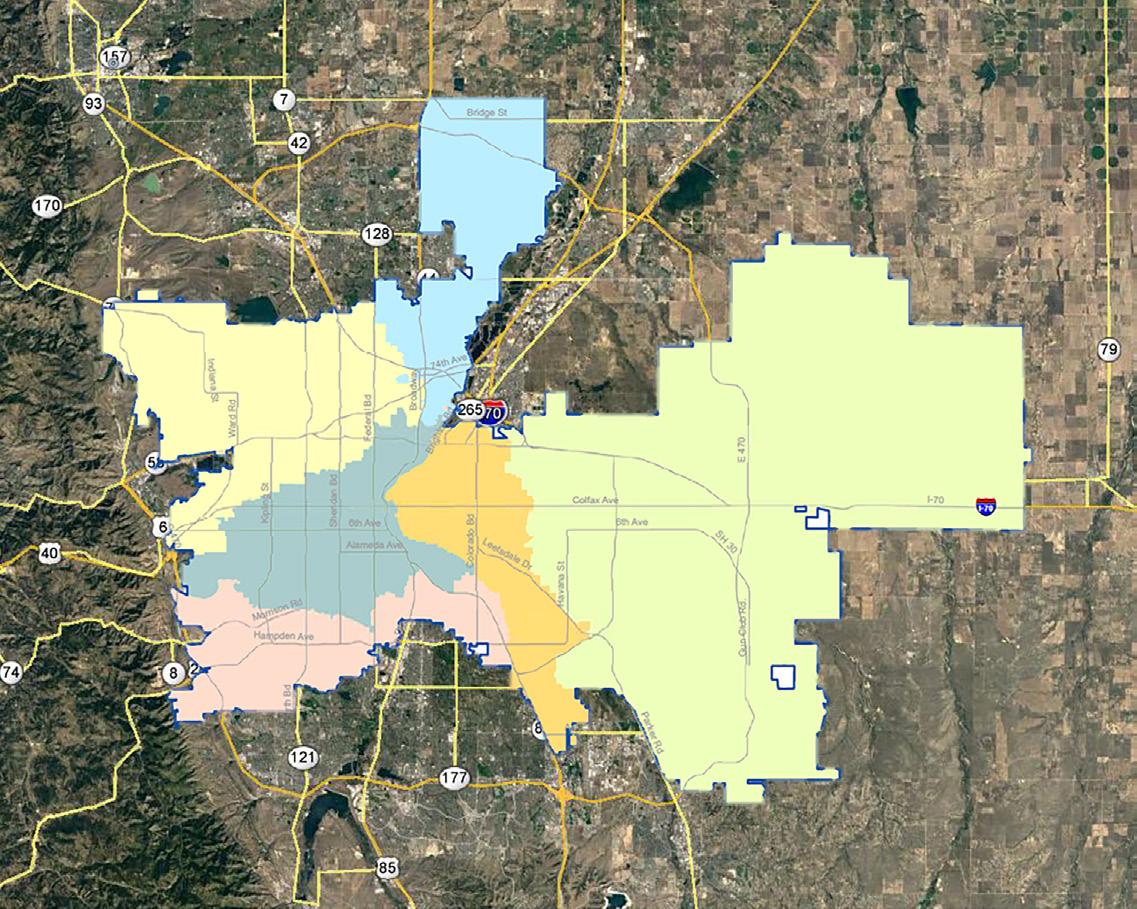

Grand Prize - DesignNorthern Treatment Plant FacilitiesEntrant: Metro Wastewater Reclamation District Entrant Profile Metro Wastewater Reclamation District's service area in Denver, Colorado. Metro Wastewater Reclamation District (Metro District or District) is a wastewater authority providing wastewater services to about 1.8 million people in a 715-square-mile service area throughout greater Denver. The District currently handles 130 million gallons of wastewater each day (mgd) at the 220-mgd Robert W. Hite Treatment Facility-the largest wastewater plant between the Mississippi River and the west coast. In 2016 the District commissioned the Northern Treatment Plant (NTP) located in Brighton, CO to provide 24 mgd of capacity for connectors northeast of Denver. The NTP uses advanced treatment prior to discharge to the South Platte River. The NTP Facilities Project is a regional project helping solve wastewater treatment needs for the northern Denver metropolitan area and highlights how a progressive design-build (PDB) delivery achieved schedule savings and cost certainty for the Metro District. The District and its Owner Advisor, Carollo Engineers, worked with the Design-Builder, CH2M now Jacobs (CH2M), to develop a project partnership that promoted team collaboration and project risk assignment that met the District's facility, budget, and schedule goals. The Metro District's treated water makes up more than 85 percent of the South Platte River nine months of the year and is suitable for agriculture, fish and aquatic life, industrial use, water supply, and recreation. The District land applies stabilized biosolids at private farms and the District's METROGRO Farm. The award winning Resource, Recovery, and Reuse programs at the District serve as a national example of stewardship of our nation's agricultural and prairie lands. Project Description

Metro Wastewater Reclamation District's service area in Denver, Colorado.

The District's NTP is the largest "greenfield" wastewater treatment facility to date in the U.S.

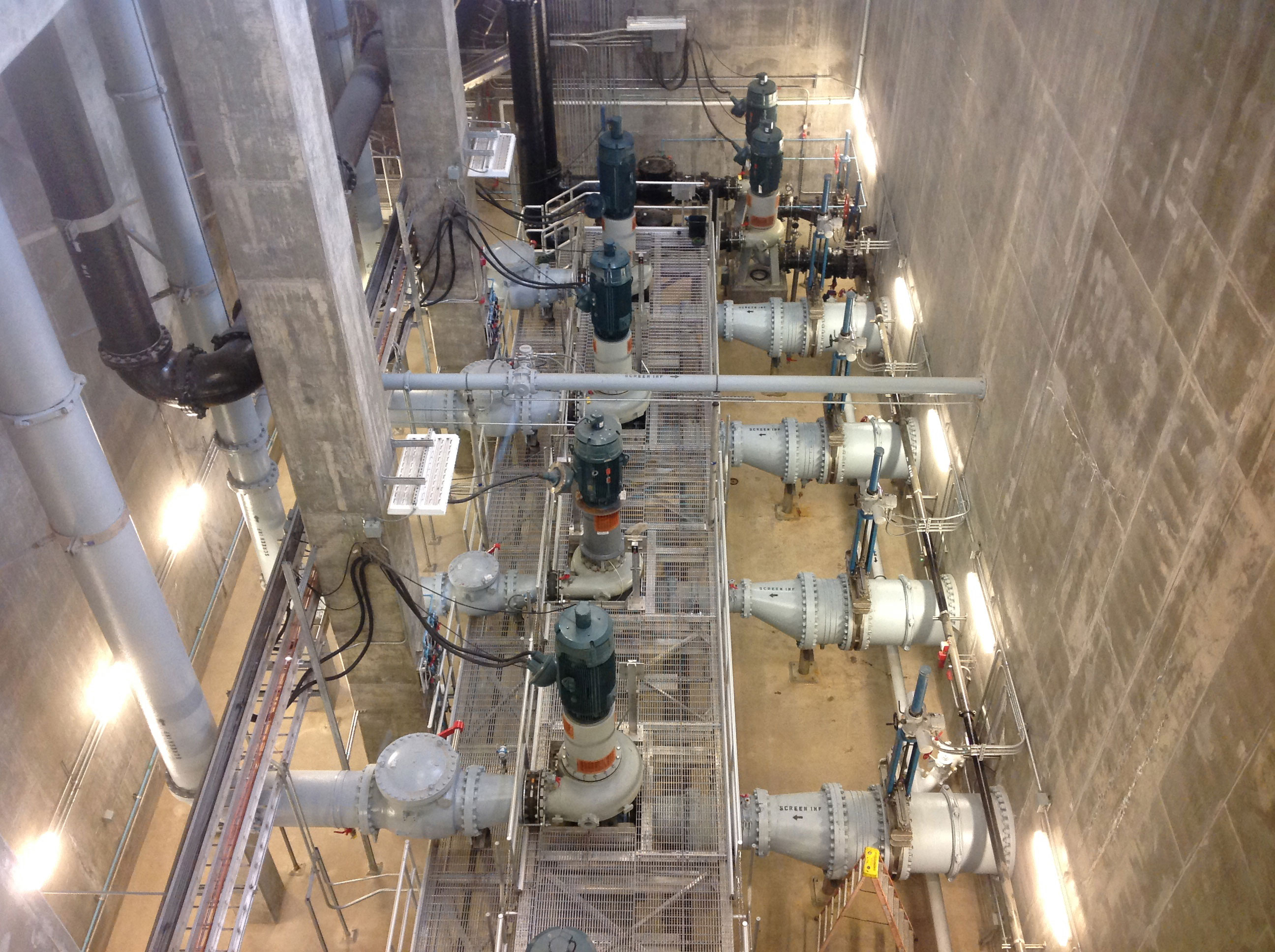

The 78-inch South Platte Interceptor delivers wastewater to the NTP where influent pumps convey water for primary and secondary treatment. Located 50 feet below ground, the Headworks Building is the deepest facility in the NTP.

Three-dimensional modeling during design facilitated interdisciplinary collaboration and more efficient cost estimate and quality reviews.

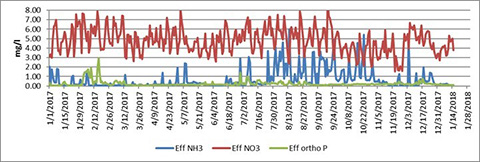

The NTP was designed to meet the most stringent effluent standards in Colorado to protect the State's natural resources. The treatment was selected to not only to meet these limits, but also to improve long-term operability, maintenance, and reliability and has consistently met permit discharge limits since commissioning.

The Administration Building at the NTP Facilities includes a Visitor's Center with interactive displays to provide educational opportunities to the public.

The project encountered several challenges in dealing with groundwater. A slurry wall was installed around the site to accommodate construction activities and long-term operations.

Dissolved oxygen in the effluent is increased prior to discharge to the South Platte River through a series of waterfalls-the centerpiece of the natural wetland buffer visitors can explore via paved trails connected to the river. Our staff is very pleased with the Facility. We believe it is quite an accomplishment for a facility of this size and complexity to be compliant from Day One!Orren West, NTP Superintendent The Largest "Greenfield" PDB WWTP in the United StatesAfter three decades of wastewater planning, the Metro Wastewater Reclamation District's $475M Northern Treatment Plant Program, including its $280M NTP Facilities, embody the spirit of regional, intergovernmental, and regulatory cooperation, and provide a consolidated approach to wastewater management. It is one of Colorado's largest and most complex wastewater projects to be contracted by alternative delivery. The project also represents the largest "greenfield" water or wastewater treatment facility in the U.S. to-date to be constructed using progressive design-build (PDB). Accordingly, the project demonstrates the collaborative spirit of PDB to meet scope, quality, budgetary, and schedule goals, and is referenced as Best Practice in the Water and Wastewater Industry. CH2M was selected as the Design-Builder based on qualifications to provide design, permitting, construction, and startup/commissioning services. Notice-to-Proceed for design was granted in August 2011 and a stipulated price was agreed upon between CH2M and the District after 14 months of design progression. The project consisted of:

Integrated ApproachA guiding principle throughout project delivery was collaboration across all project partners. Starting with the District and its Owner Advisor, the program's vision and goals were developed and included for the entire design-build team. Partnerships across local and regional entities were created through intergovernmental agreements. Collaboration and management systems, work flows, decision-making, and issue escalation procedures were defined to integrate all program partners into an enterprise delivery. This theme of integration also carried through the design.-optimizing treatment while minimizing construction and operation costs. The design met the District's commitment to enhance the South Platte River while minimizing impacts to the community and environment through:

QualityQuality was an important project component in every step of delivery. The Design-Builder's Quality Management Plan (QMP) was paramount. Although QA/QC was led by the Design-Builder, established quality objectives were the responsibility of everyone. The design QA/QC manager ensured QMP processes were properly implemented and that all requirements were met. Construction personnel were also responsible for QC and third-party testing and inspections were performed as a redundant quality check. User SatisfactionAt the 30 percent design, the team initiated a series of steps to ensure the project met budget expectations. This resulted in a 19 percent cost reduction at 70 percent design. Construction was completed under budget and on-schedule with a change order rate of 1.3 percent. Additionally, early delivery and occupation of the FSB lowered operation costs. PerformanceSince commissioning, the NTP has consistently met permit requirements. Originality and InnovationThe project had many innovative features to minimize operational costs and maintain flexibility for future regulations including:

Elements of Project Delivery

The FSB and Visitor's Center are additional original and innovative project elements. The FSB is unique in that it includes the plant controls and laboratory and also has a library, locker rooms, private offices, open office area, vehicle and maintenance shops, and a warehouse. ComplexitySome of the project challenges met included: Schedule constraints, which were alleviated by:

To gain public support for the project, and ensure NTP becomes a community asset, the team established a communication and outreach plan to obtain input from the surrounding community. Gaining regulatory approval was unchartered for the first and largest PDB in the State. The team worked closely with the Colorado Department of Public Health and Environment to coordinate on the review and appropriate approvals. A portion of the site was located within the 100-year floodplain. Coordination with regulatory agencies began during planning, allowing the District to minimize requirements of the Design-Builder. The site's high groundwater table had elevated concentrations of naturally occurring metals. To alleviate impacts on construction and long-term operations, a slurry wall was installed around the site. To alleviate impacts from the metals, dewatering discharges from different areas of the site were blended to meet the groundwater discharge parameters. Risk allocation was a concern for the District's first experience with PDB. The District and Design-Builder engaged in a detailed risk analysis that identified and quantified, and appropriately allocated over 150 risks for the project. In September 2013, during construction, Colorado experienced historical flooding that impacted the project site and construction activities, including significant flooding of the deepest excavation on the site. The Design-Builder worked diligently to dewater and clean the impacted areas while keeping the project scope and schedule on track. Social and Economic AdvancementEarly in the project, the District made a commitment to deliver a facility that would be viewed as an asset to the community and continue their environmental stewardship. The team met this commitment in several ways:

Click images to enlarge in separate window. Click here to return to the list of 2018 winners. |