- Home

- Contact Us

- News & Events

- Awards

- AAEES Awards Criteria

- 40 Under 40 Recognition Program

- Edward J.Cleary Award

- Excellence in Environmental Engineering and Science Education

- Gordon Maskew Fair Award

- Honorary Member

- International Honorary Member

- Ralph and Joe Bales Graber Science Award

- Stanley E. Kappe Award

- Environmental Communications Awards Competition

- Excellence in Environmental Engineering and Science Competition

- The AAEES Chapter Blue Marble Award

- Resources

- AAEES Microcredentials

- Annual Reports

- AAEES Press Releases

- AAEES Website How To VIdeos

- Environmental Engineer and Scientist

- Environmental Engineering Body of Knowledge

- PFAS Resources

- Specialty Examination Guide

- Students and Young Professionals Resources

- Who's Who in Environmental Engineering & Science®

- Leadership Opportunities

- Membership

- Donate

- Jobs

2017 Excellence in Environmental Engineering and Science® Awards Competition Winner

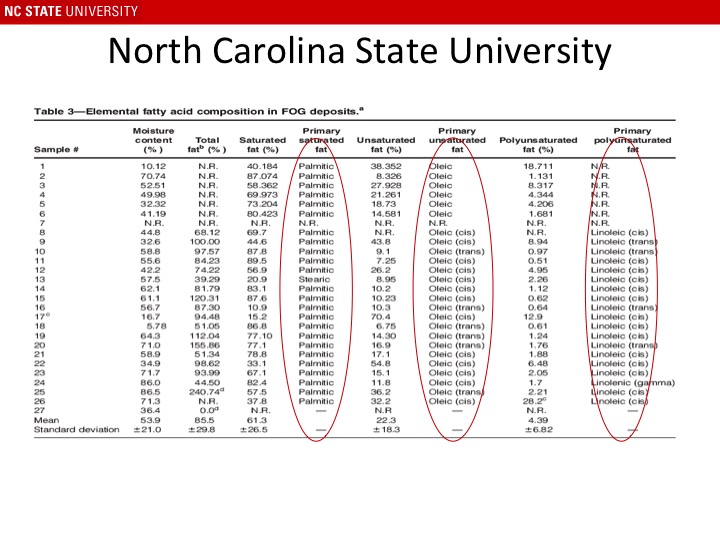

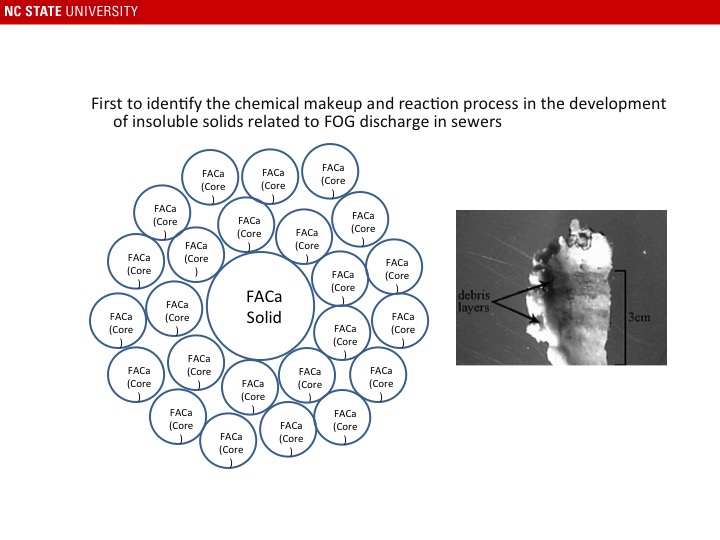

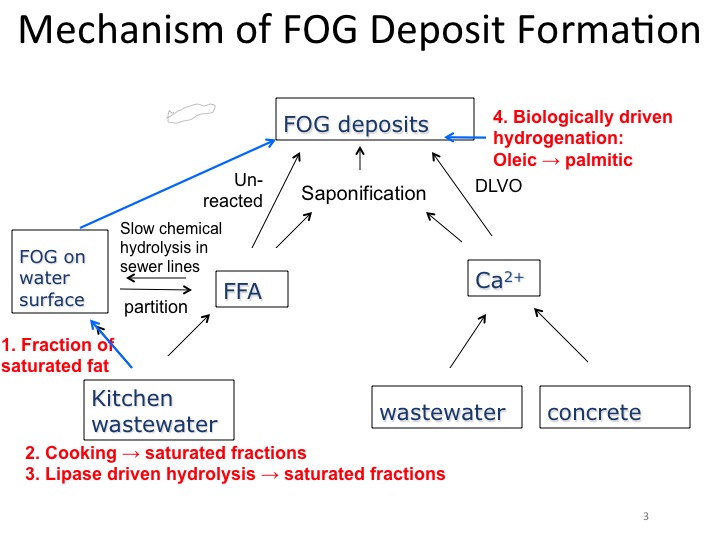

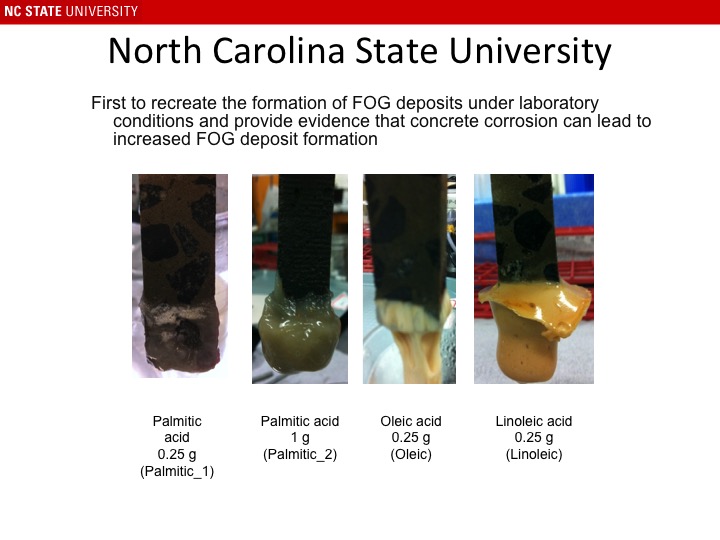

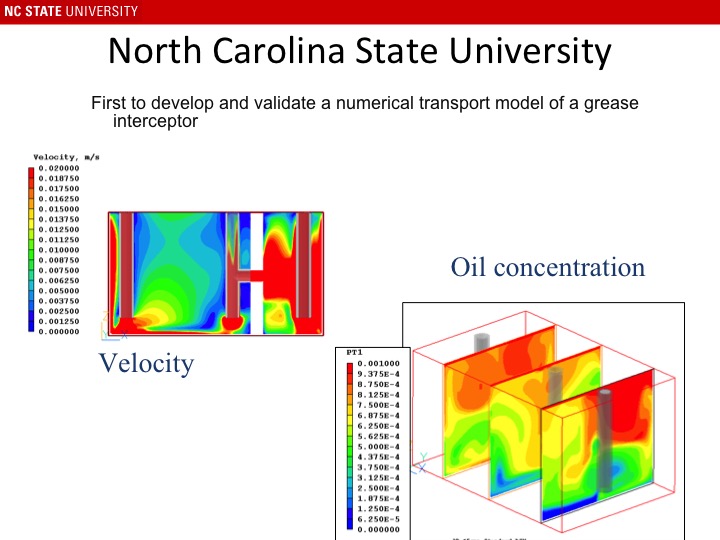

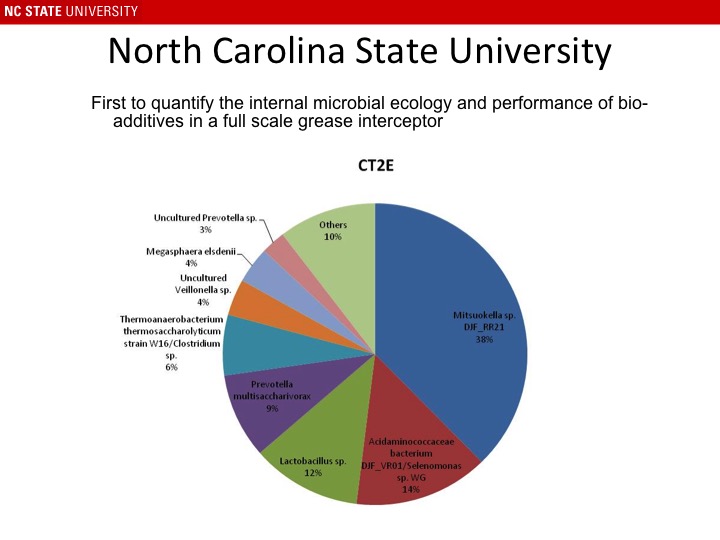

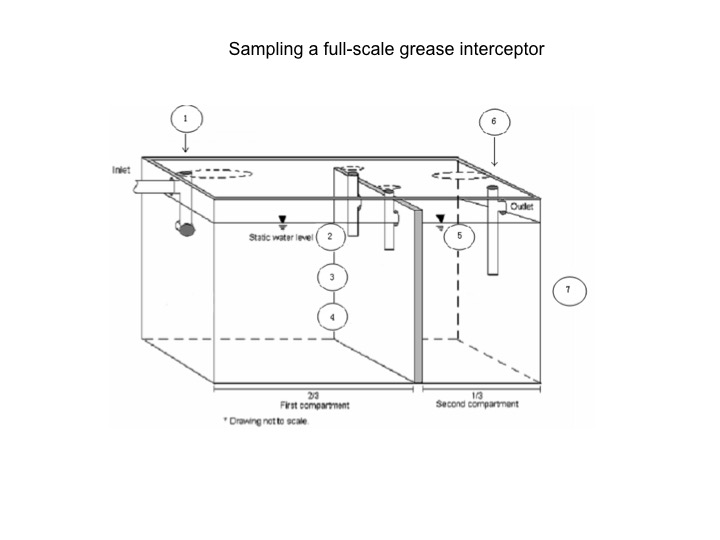

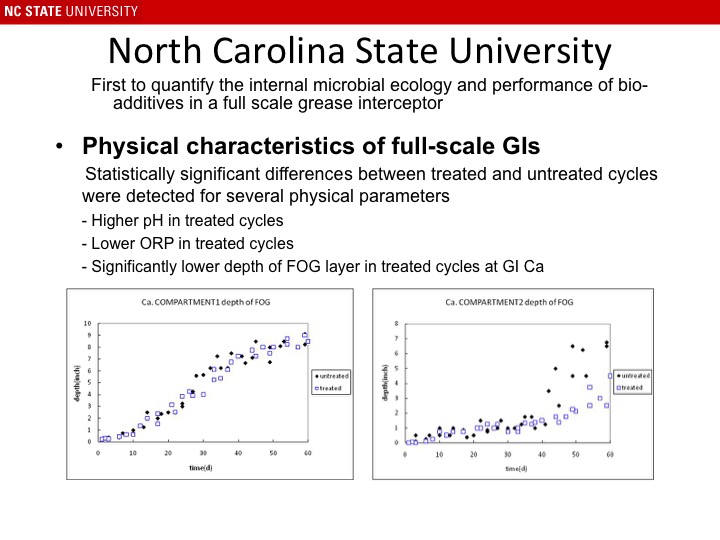

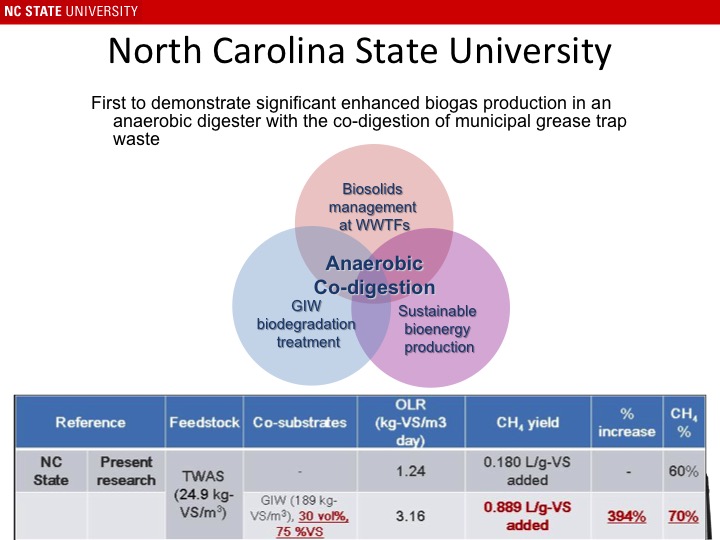

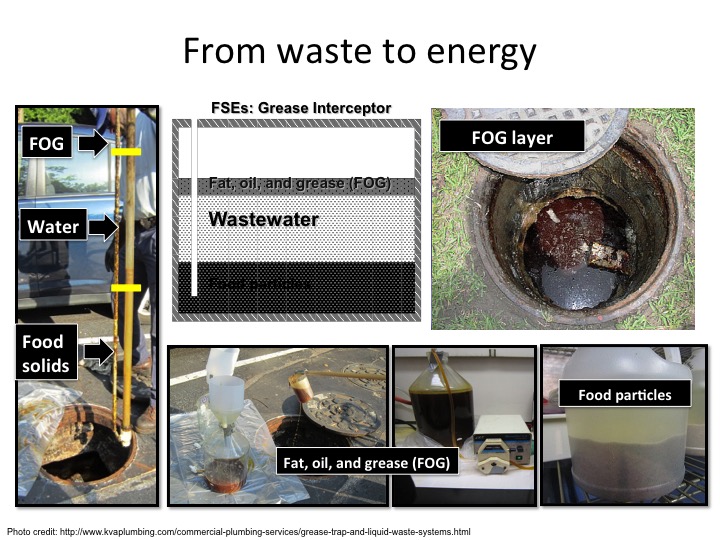

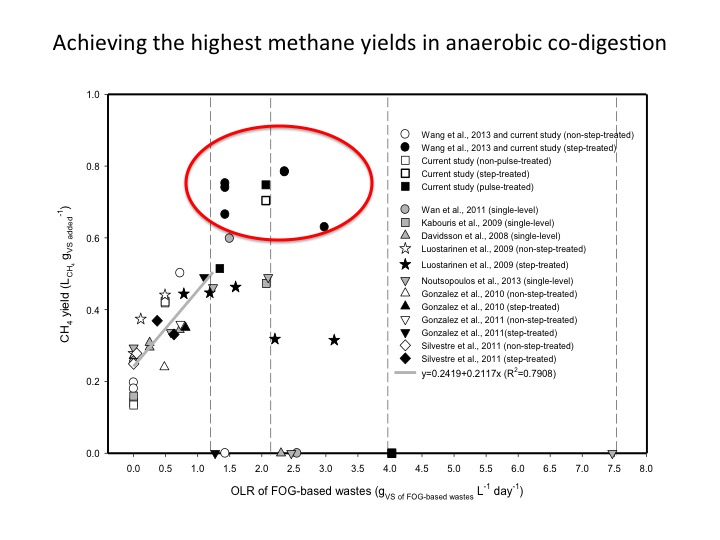

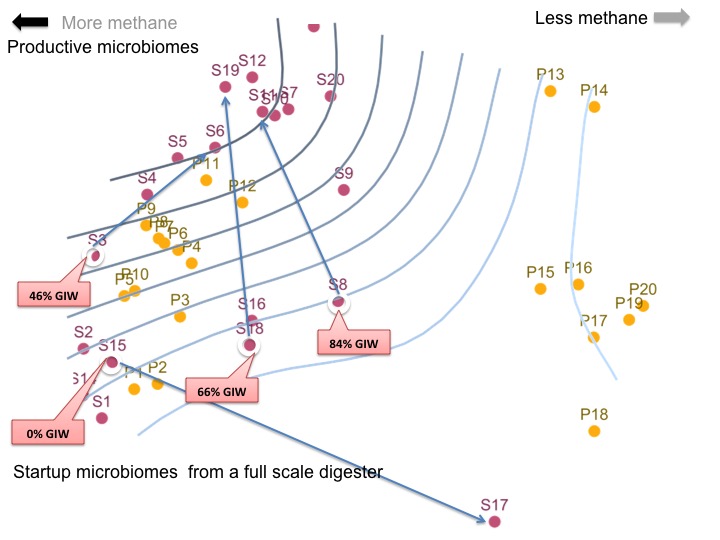

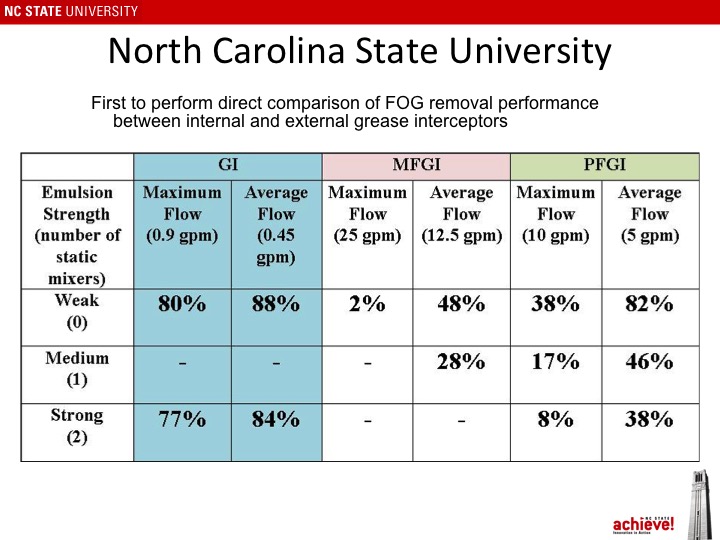

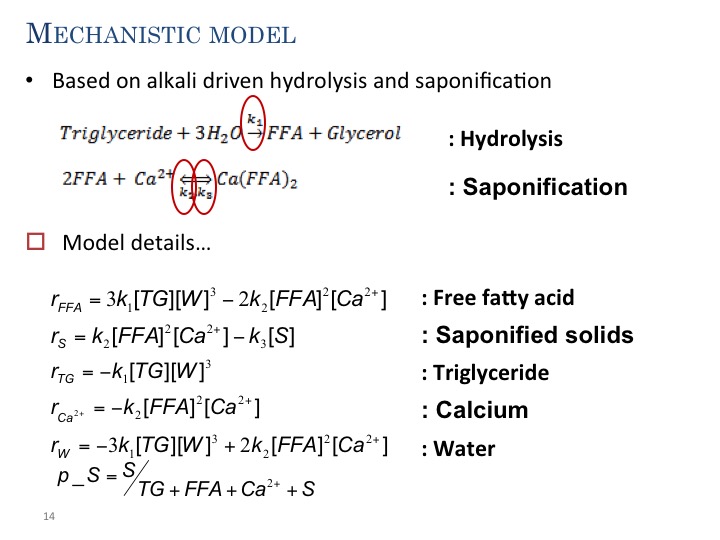

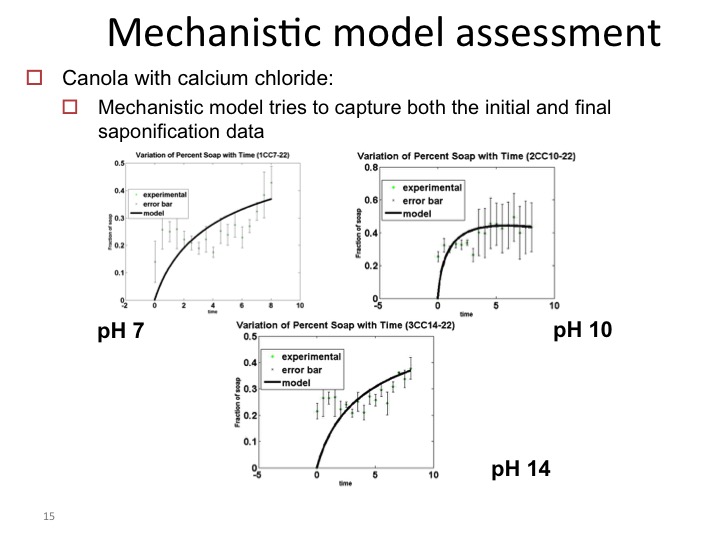

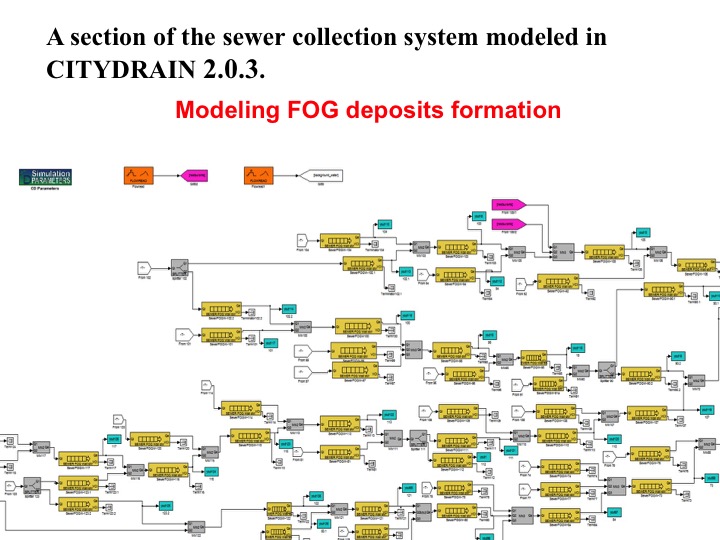

Honor Award - University ResearchFats, Oils, and Grease (FOG) Waste: Fate and Transport in Interceptors and Sewers, Energy and Recovery Through Anaerobic Co-DigestionEntrant: North Carolina Research Team: Dr. Joel J. Ducoste, BCEEM, Dr. Francis L. de los Reyes, III,  Entrant ProfileDr. Joel J. Ducoste is a Professor in the Civil, Construction, and Environmental Engineering (CCEE) Department at North Carolina State University. Dr. Ducoste is a national and international recognized expert in modeling water and wastewater treatment processes using Computational Fluid Dynamics (CFD). His current research interests include physico-chemical processes in water treatment, chemical and UV disinfection, advance oxidation, water/wastewater process optimization, wastewater sewer collection system sustainability, energy recovery from wastewater systems. Dr. Francis L. de los Reyes III is a Professor in CCEE and a University Faculty Scholar. Dr. de los Reyes' research focuses on biological processes and combines modeling, bioreactor experiments, and molecular microbial ecology tools in addressing fundamental and practical issues in environmental biotechnology and environmental engineering. Another research focus is sanitation in developing countries. He is interested in two main areas: the interface between microbial ecology and environmental engineering, and global sanitation. Dr. Tarek N. Aziz is an Assistant Professor in CCEE. Dr. Aziz is interested in the interface of biological and chemical processes and environmental fluid mechanics. His research has involved investigation of anaerobic digestion for enhanced energy production in wastewater treatment, removal of FOG from wastewater, and the impact of natural and artificial mixing in lakes on biological processes in those systems. Drs. Ducoste, de los Reyes, and Aziz collectively worked on the project and planned out the set of experiments and modeling work performed by graduate students to help understand the physical and chemical makeup of FOG deposits, the FOG transformation and removal processes, and its biological conversion into biogas using anaerobic co-digestion in municipal wastewater treatment. Dr. Ducoste took the lead in FOG deposit characterization, CFD and design of grease interceptors, measurement of FOG using advanced methods. Dr. de los Reyes took the lead in microbial ecology of grease interceptors, impact of bioadditives, and anaerobic co-digestion bioreactor operation and microbial analysis. Dr. Aziz took the lead in techno-economic assessment of anaerobic co-digestion of FOG. Project DescriptionWhen fat, oil, and grease (FOG) are released into the sewer collection system, they accumulate on pipe walls, which reduces their conveyance capacity. This reduced capacity results in the uncontrolled discharge of untreated sewage into the environment, which is referred to as a sanitary sewer overflow (SSO). According to the U.S. EPA, roughly 3–10 billion gallons of sewage are discharged illegally into the environment each year as a result of SSOs. FOG accumulation represents 47% of all blockage-based sanitary sewer overflows. For decades, the science and engineering of FOG deposit formation, grease abatement devices, and energy recovery from FOG wastes have been largely neglected. Over the last 11 years, our research team has systematically performed novel and important research in FOG deposit formation in sewer lines, optimizing and characterizing grease interceptors (GIs), and recovering methane using anaerobic co-digestion of FOG wastes. Our research group is perhaps the leading research group in the world in these areas, and the collective efforts have led to many scientific and engineering research "firsts":

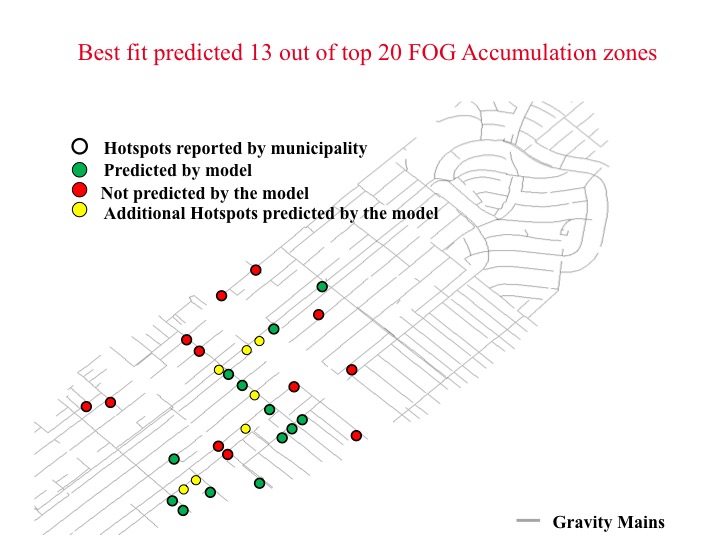

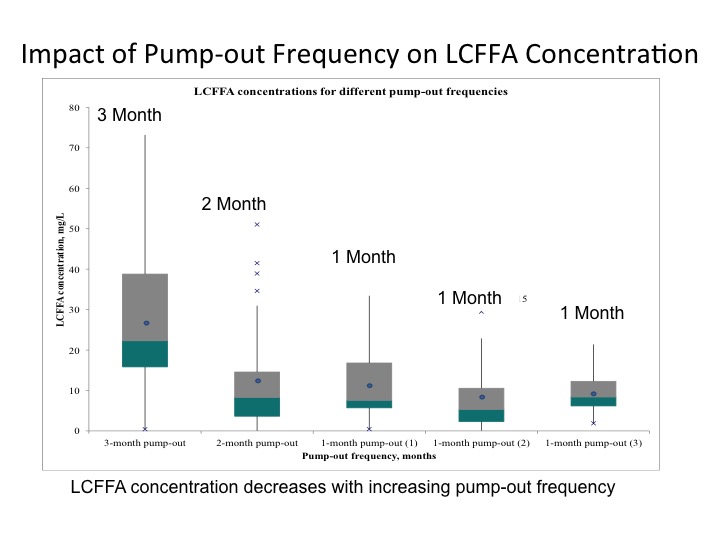

IntegrationOur research focus has two prongs: addressing the fundamental scientific questions in FOG fate, transport, and recovery of energy; and developing approaches and technologies for SOLVING the problem of FOG deposit formation and maximizing energy recovery. We consider the entire problem from when it is produced in food service establishments, to separation and degradation in grease interceptors, to what happens in sewer lines, to how it can be treated in a way that recovers energy, to how different municipalities with varying capacities can decide if anaerobic co-digestion is economical. QualityThe research we performed has been reported in 15 peer-reviewed papers (in leading journals such as Environmental Science and Technology, Water Research, Applied Microbiology and Biotechnology), 30 conference presentations (oral and poster), 6 research reports (for EPA, WERF and NC WRRI). The research has funded 8 graduate students (all theses or dissertations). The quality of the research is also documented in the support letters from academics, consulting engineers, and municipalities, who are either experts in the field or end-users/beneficiaries. Originality and InnovationFor decades, FOG research (fate in sewer lines, FOG measurement, microbial ecology and physical modeling of GIs, anaerobic co-digestion of FOG waste) has been fragmented and lacking. As outlined above, we have achieved a number of "firsts", all of which are the result of our focus on answering key fundamental questions (e.g., "How do FOG deposits form? What happens inside a grease interceptor?"), and aiming for solutions (e.g., "Where in a network will blockages likely develop? How can we re-design the grease interceptor? How can we recover energy from FOG?"). The NC State team is perhaps the leading research group in this field, and each of the published peer reviewed papers present original and innovative approaches and results. ComplexityTo accomplish the different goals of this project, the research team had to use methods and approaches from different spheres of science and engineering: physical processes (hydraulics, design of GIs), chemical processes (saponification reactions, measurement using FTIR), biological processes (molecular microbial methods such as 16S rRNA gene analysis, anaerobic digestion), and computational methods (CFD, numerical transport, techno-economic analysis). The scope of the project included analyzing multiple aspects of food waste chemistry, corrosion chemistry, microbiology, mathematical modeling, and process engineering. The approaches included lab-scale experiments, field observations, and numerical methods. Contribution to Social and Economic DevelopmentAn NREL survey of thirty US metropolitan areas shows that FOG is generated at a rate of approximately 1.88 gallons FOG/person/year. This is an estimate of only the FOG portion of GIW and does not include food solids. A survey of a North Carolina metropolitan area determined that, including the entire contents of the GI, there is an average of 18.65 gallons/person/year. Based on these estimates, there are approximately 5.8 billion gallons of grease interceptor waste (GIW) in the United States. GIW has a high biochemical oxygen demand, and the dewatered GIW contains roughly 7,000-10,000 BTUs/pound. Based on the above estimates, the co- digestion energy yield would be approximately 22,000–32,000 GWh/yr or 60% of the energy demand for the entire water and wastewater industry. This potential is the reason why municipalities such as the City of Raleigh are investing in FOG co-digestion (see letter of support). Similarly, the problem of FOG deposits and sewer blockages is important to many municipalities in the US and in other countries such as the UK (see letter from Cranfield University). The research at NC State University has provided new areas of investigation in preventing FOG deposits, maximizing methane production, developing new measurement techniques for FOG, and developing new tools for predicting blockage hotspots. These advances contribute directly to environmental protection, sustainable energy production, and economic development. Click images to enlarge in separate window. Click here to return to the list of 2017 winners. |