- Home

- Contact Us

- News & Events

- Awards

- AAEES Awards Criteria

- 40 Under 40 Recognition Program

- Edward J.Cleary Award

- Excellence in Environmental Engineering and Science Education

- Gordon Maskew Fair Award

- Honorary Member

- International Honorary Member

- Ralph and Joe Bales Graber Science Award

- Stanley E. Kappe Award

- Environmental Communications Awards Competition

- Excellence in Environmental Engineering and Science Competition

- The AAEES Chapter Blue Marble Award

- Resources

- AAEES Microcredentials

- Annual Reports

- AAEES Press Releases

- AAEES Website How To VIdeos

- Environmental Engineer and Scientist

- Environmental Engineering Body of Knowledge

- PFAS Resources

- Specialty Examination Guide

- Students and Young Professionals Resources

- Who's Who in Environmental Engineering & Science®

- Leadership Opportunities

- Membership

- Donate

- Jobs

2017 Excellence in Environmental Engineering and Science® Awards Competition Winner

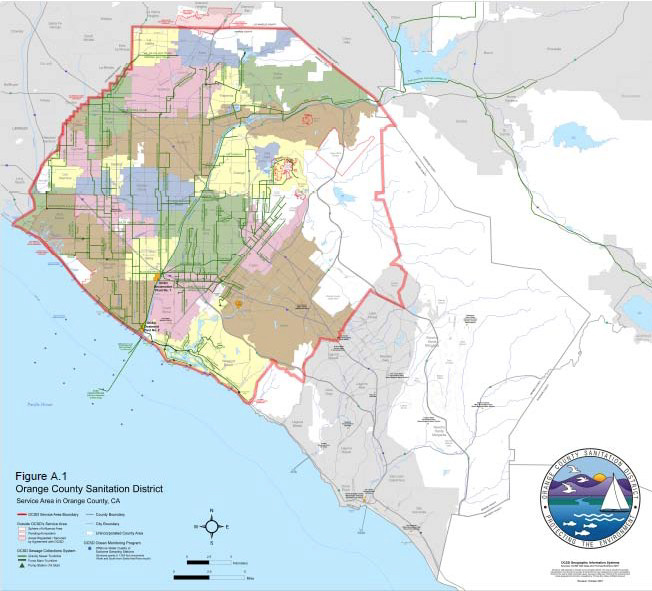

Honor Award - PlanningBiosolids Master PlanEntrant: Orange County Sanitation Districts  Entrant ProfileThe Orange County Sanitation District (OCSD) is committed to protect public health and the environment by providing effective wastewater collection, treatment, and recycling. OCSD provides regional treatment and disposal of domestic, commercial and industrial wastewater for central and northern Orange County, California. In addition, OCSD provides approximately 100 MGD of secondary treated wastewater to the Groundwater Replenishment System (GWRS), a joint regional water reclamation program initiated jointly by OCSD and the Orange County Water District. OCSD operates wastewater treatment plants in Fountain Valley (Plant No. 1) and Huntington Beach (Plant No. 2) (See Figure A.1). The OCSD is governed by a 25-member Board of Directors which represents the 20 individual cities, four special districts, and unincorporated areas of the County. Collectively, OCSD serves an area of approximately 479 square miles. Currently, O CSD facilities consist of approximately 570 miles of trunk sewer systems and force mains, 15 offsite pump stations, two wastewater treatment plants, which treated approximately 188 million galls per day (MGD) of wastewater, and two ocean outfall pipelines (located offshore of Huntington Beach and Newport Beach). OCSD's facilities are operated and administered by a professional staff of about 626 persons between Plant No. 1 (headquarters) and Plant No. 2.

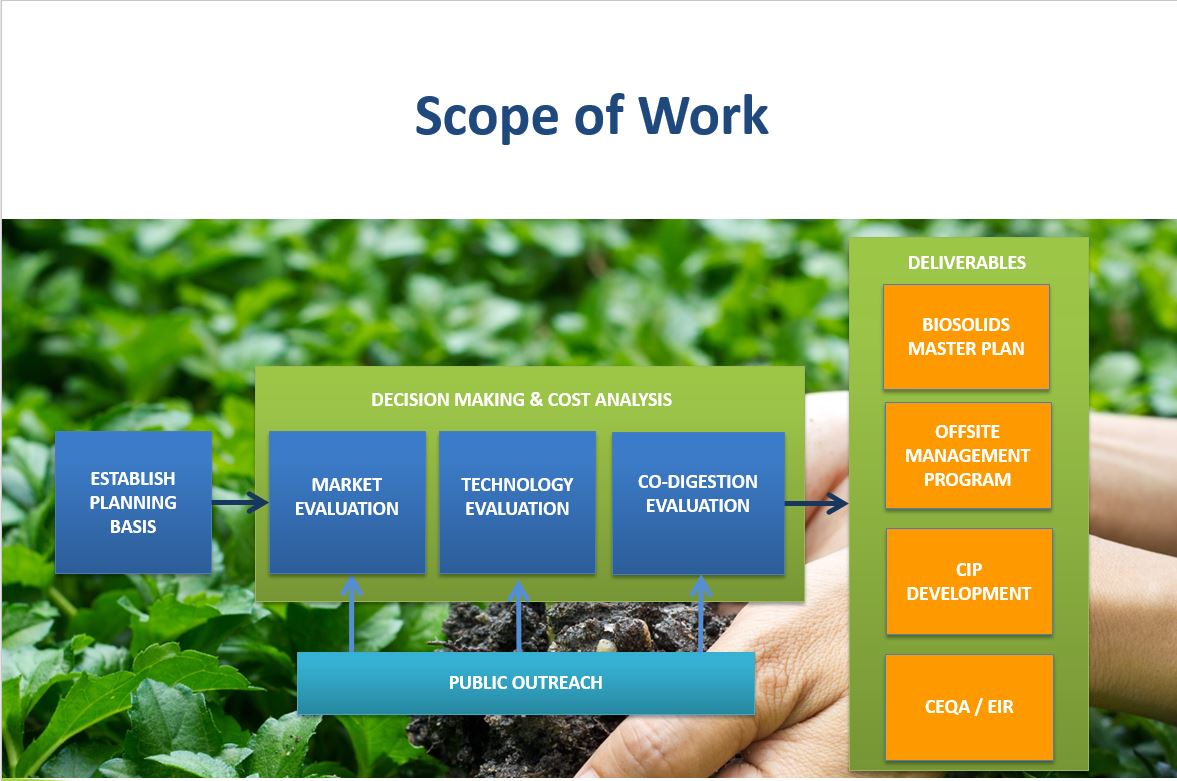

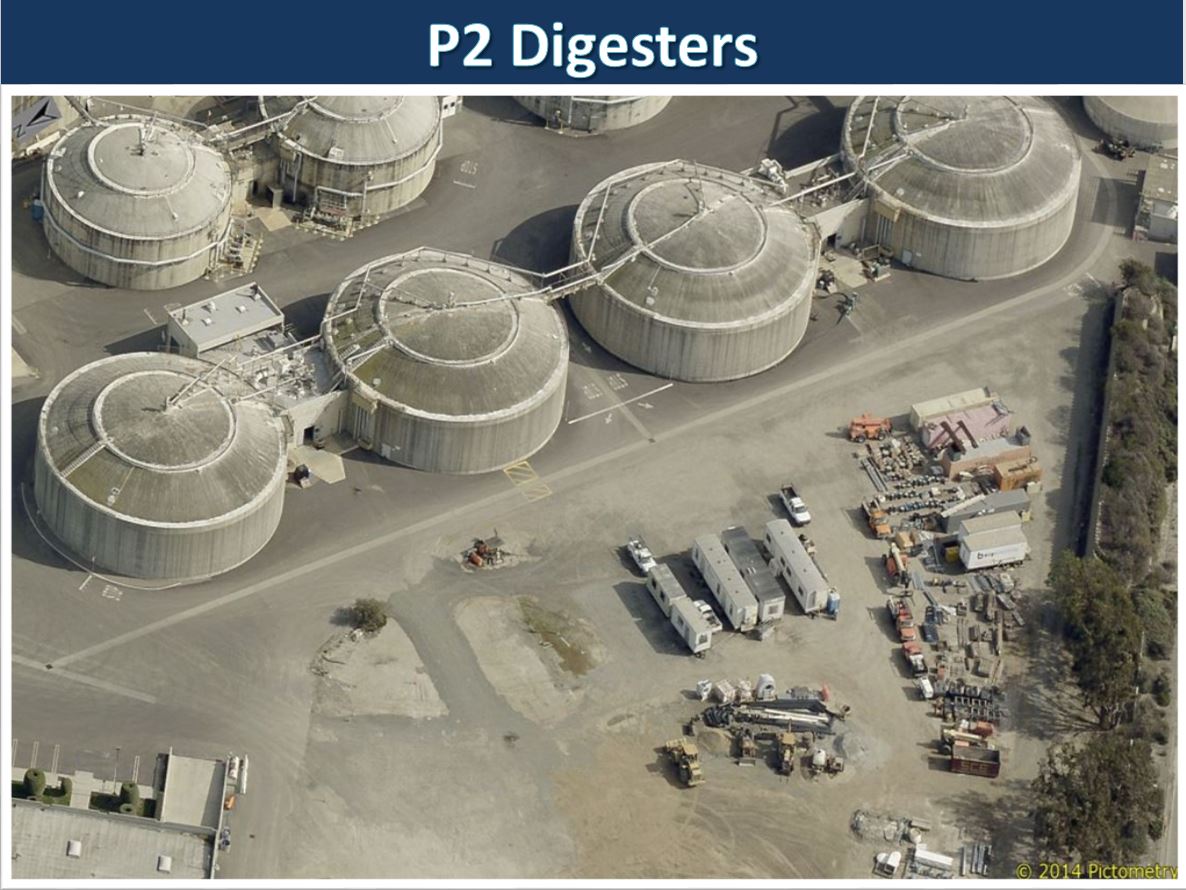

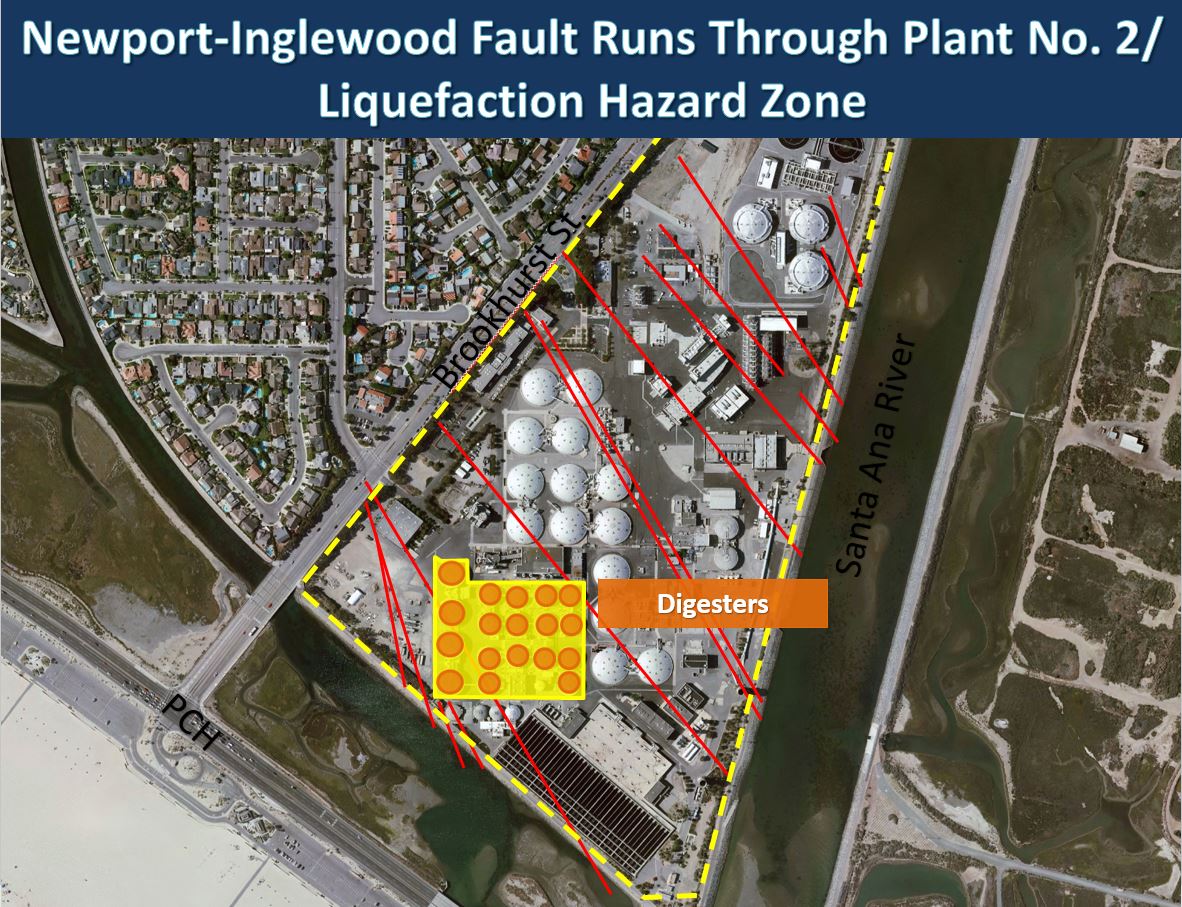

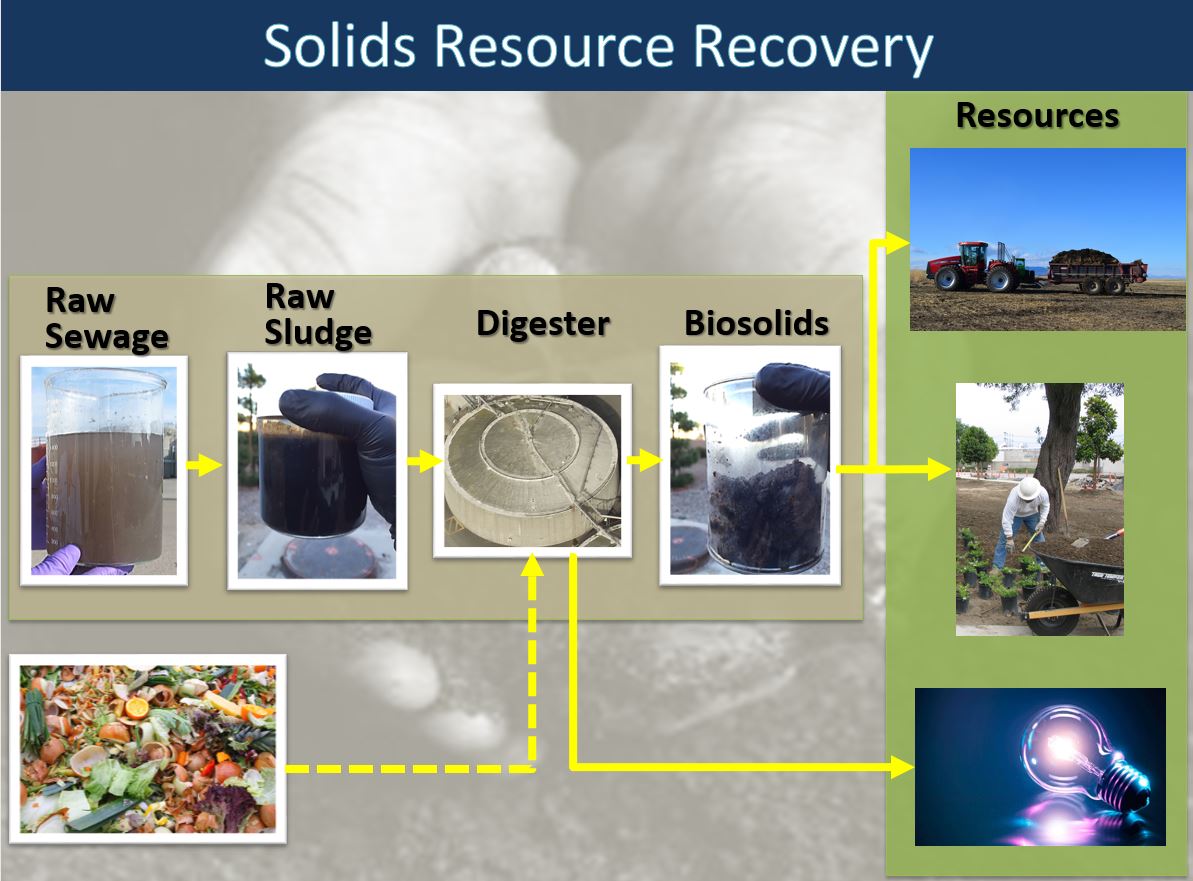

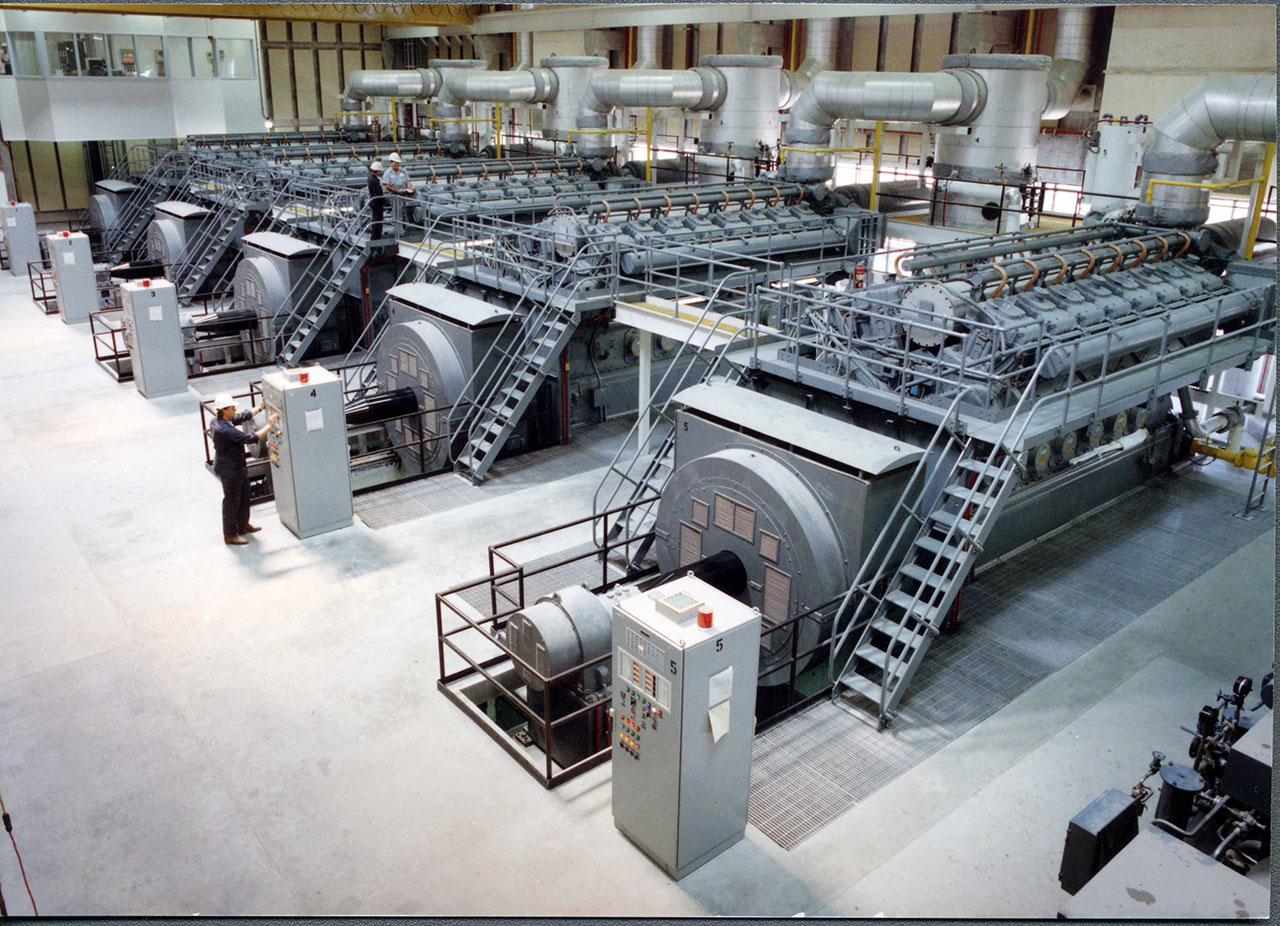

Project DescriptionOverviewIn January 2016, the Orange County Sanitation District (OCSD) and its consultant team of Black & Veatch/Brown and Caldwell embarked on a significant planning project to provide a long-term framework for a sustainable, cost-effective biosolids management program. After a year-long evaluation process, a state-of-the- art, end-to-end biosolids master plan emerged, aligning the appropriate biosolids products, markets, levels of treatment, resource recovery, and facilities improvements in a roadmap for the next 20 years of operation. OCSD's Biosolids Master Plan (BMP) is one of the most comprehensive biosolids planning efforts ever done. Comprehensive, Integrated Approach to Environmental MediaOCSD's BMP is an integrated approach to land, water and air. OCSD's two secondary treatment plants produce effluent for ocean discharge and the Groundwater Replenishment System, which recycles 100 million gallons per day for maintaining groundwater in Orange County. The plants also produce nutrient rich biosolids as a byproduct. OCSD's BMP continues and expands the process of beneficial use of biosolids. Bulk land application and composting of the Class B product has traditionally been OCSD's biosolids management process. The BMP opens more opportunities for beneficial use for local agriculture and soil blending by identifying treatment technologies to produce Class A Exceptional Quality biosolids. The BMP also continues best practice odor and emissions control, incorporating mitigation elements in the recommended capital improvement program (CIP), including those for high-strength organic waste. Further, Class A biosolids production will reduce biosolids odors and emissions associated with product hauling. QualityThis complex project, completed on budget and on schedule, accounts for all aspects of OCSD's biosolids operation – from biosolids market exploration to the recommended implementation of new, compatible technologies to enhance operations and the end product, while capturing opportunities for resource recovery. Producing such a comprehensive plan required considerable time to survey the biosolids market; evaluate technologies, identify challenges, drivers and regulations; examine similarly-sized treatment works in the Western U.S.; factor in location-specific seismic risks and other environmental and community concerns. It required a close look at current and future operations and a thoughtful eye to ensure uninterrupted operations through the long process of implementing the proposed facilities. Ultimately, the BMP meets OCSD's goal of planning future biosolids management strategies and CIP projects over a 20-year period. Moreover, it's a roadmap of critical steps for the development and advancement of a truly sustainable biosolids management program. Originality and InnovationOne focus was to explore Plant No. 2's capability to receive and process high-strength organic waste (i.e. food waste). Another was to develop digestion technology alternatives. Temperature-phased anaerobic digestion (TPAD), the plan's recommended technology, offers several important synergies, including excellent compatibility for processing food waste. In fact, it enhances biosolids product quality to Class A. TPAD also offers operational flexibility for the distinct seismic concerns at Plant No. 2. Thermophilic digestion is a key step for OCSD to produce Class A biosolids. In sequencing outlined in the BMP, new thermophilic digesters would be implemented before mesophilic. Thus, in the event of an earthquake before installation of mesophilic digestion, OCSD could still process food waste and produce its highly marketable Class A product. Implementing food waste receiving facilities was a significant and timely development. By state law, commercial food waste may no longer be hauled to landfill. With planned food waste facilities at Plant No. 2, food waste pre-processors will now have a product outlet which can also increase biogas production and with it, additional power from OCSD's co-generation facilities. From food waste receiving to biogas generation to the production and beneficial use of Class A biosolids, OCSD's facilities represent resource recovery at its finest. ComplexityThe scope included numerous tasks to evaluate current practices, loadings, prior plans and technologies as well as weighing options against economic, non-economic, social and environmental factors. The site presents complexities. The team faced space constraints for developing concepts at Plant No. 2. This required significant site planning, a geotechnical study and sequencing strategies. The BMP recommends phasing out aging equipment with new digesters that satisfy current seismic design criteria. The compact site and the imperativeness of maintaining operations through a carefully sequenced plan took the complexity to a unique level. The team faced challenges of integrating new biosolids facilities and digester upgrades within an existing plant's onsite power production. With a boost in biogas production from new digesters, the team carefully planned impacts on existing operations and engine function. TPAD also affects the recovery of waste heat from engine generators. With a raised in operating temperature in the digesters, the BMP guides modification of the waste heat recovery system. The BMP also recommends the use of plant effluent as onsite cooling water to bring digester sludge from thermophilic to mesophilic temperatures, and it addresses ways to mitigate corrosion. Contribution to Social and Economic AdvancementOCSD values its stakeholder needs and desires. Through several public meetings and neighborhood workshops, the community helped to shape OCSD's plan. OCSD gains an energy recovery boost by receiving food waste in conjunction with TPAD. Already, OCSD produces enough on-site power through its Central Generation facilities to run approximately two-thirds of the wastewater treatment operation. TPAD and food waste processing means even less power purchased from the grid. Food waste receiving at Plant No. 2 opens a new potential revenue stream for OCSD. It's an excellent fit for pre-processors of food waste, and regulations regarding organic waste will expand in the future. Thus, OCSD becomes part of the solution for a public challenge. TPAD opens more markets for OCSD's biosolids to be used locally. Long hauling trips are reduced – and the trucks will be hauling a less odorous product. The circular economy aspect of beneficially using Class A biosolids to grow food and enrich soil quality illustrates a holistic approach that's sure to draw social praise. Click images to enlarge in separate window. Click here to return to the list of 2017 winners. |