- Home

- Contact Us

- News & Events

- Awards

- AAEES Awards Criteria

- 40 Under 40 Recognition Program

- Edward J.Cleary Award

- Excellence in Environmental Engineering and Science Education

- Gordon Maskew Fair Award

- Honorary Member

- International Honorary Member

- Ralph and Joe Bales Graber Science Award

- Stanley E. Kappe Award

- Environmental Communications Awards Competition

- Excellence in Environmental Engineering and Science Competition

- The AAEES Chapter Blue Marble Award

- Resources

- AAEES Microcredentials

- Annual Reports

- AAEES Press Releases

- AAEES Website How To VIdeos

- Environmental Engineer and Scientist

- Environmental Engineering Body of Knowledge

- PFAS Resources

- Specialty Examination Guide

- Students and Young Professionals Resources

- Who's Who in Environmental Engineering & Science®

- Leadership Opportunities

- Membership

- Donate

- Jobs

2017 Excellence in Environmental Engineering and Science® Awards Competition Winner

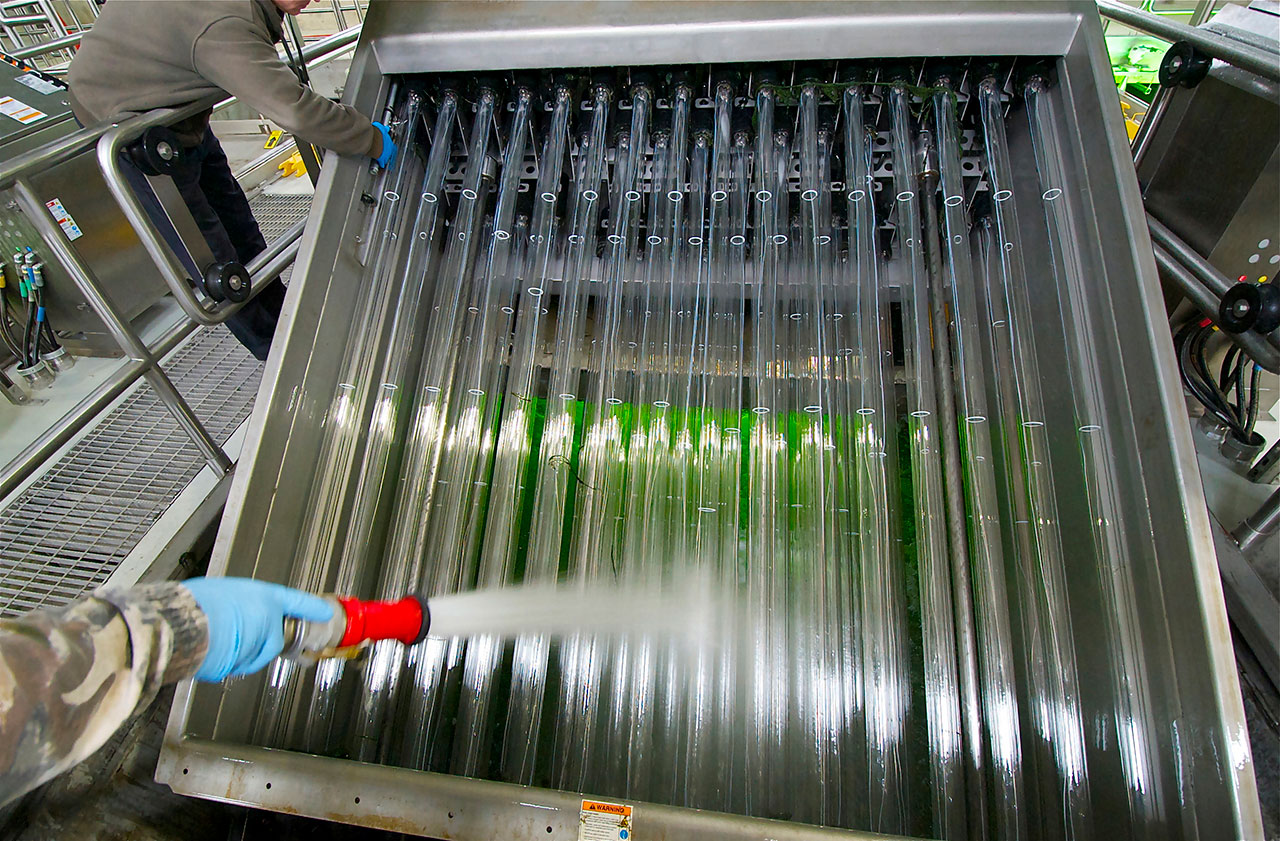

Honor Award - DesignO'Brien WRP Adds Wastewater UV Disinfection SystemEntrant: Greeley and Hansen  Entrant ProfileThe unique, innovative, and cost-saving design of the new $61.7 million ultraviolet (UV) disinfection system at the Metropolitan Water Reclamation District of Greater Chicago's (MWRD) Terrence J. O'Brien Water Reclamation Plant (WRP) features a cutting-edge application of UV technology for the world's largest wastewater UV system by flow capacity. The project exceeded MWRD requirements for flexible operation and sustainable design, while significantly improving water quality and making the Chicago Area Waterway System cleaner for recreational use and community development. Greeley and Hansen was the lead engineer responsible for overall design engineering and construction management of the MWRD's O'Brien Water Reclamation Plant UV disinfection system project. Other design consulting companies involved in the project were: Alden Research Laboratory, Inc for computational fluid dynamics modeling of the UV disinfection channels; Environmental Design International, Inc for civil site engineering services; Ground Engineering Consultants, Inc for geotechnical engineering services; Hibbard Inshore Inc for conduit inspections; Intelligent Design and Construction Solutions, LLC for instrumentation and controls engineering services; Klein and Hoffman for conduit inspection; MPR Engineering Corporation for cost estimation and other professional engineering services; Raimonde Drilling Corporation for soil borings; and Rubinos and Mesia Engineers, Inc. for structural engineering. Project DescriptionOverviewWhen a blue-ribbon panel commissioned by the Metropolitan Water Reclamation District of Greater Chicago (MWRD) recommended ultraviolet (UV) disinfection technologies for safeguarding and enhancing water quality throughout the Chicago Area Waterway System, the MWRD engaged Greeley and Hansen to design and oversee construction of the world's largest wastewater UV disinfection system by flow capacity. The $61.7 million UV disinfection system project at the Terrence J. O'Brien Water Reclamation Plant (WRP) involved the innovative application of the latest UV disinfection technology and an integrated approach for reducing pathogens in treated effluent water released into the North Shore Channel and Chicago River. The O'Brien WRP processes up to 450 million gallons of wastewater per day for more than 1.3 million Chicago-area residents. Integrated ApproachEncompassing an array of economic, social, and environmental considerations, the integrated approach of the O'Brien WRP UV disinfection system project achieved all design and construction goals for the MWRD, and was completed on schedule, within budget — and at substantially less cost than the original estimate. The expedited project required close collaboration between the MWRD, the Illinois EPA (IEPA), Greeley and Hansen, subconsultants, and construction contractors to rapidly design and construct a large-capacity UV disinfection system for the O'Brien WRP, designed to meet MWRD commitments to improve water quality for its customers, the IEPA, and environmental groups. Preliminary design of the UV disinfection system was completed within only seven weeks, comprehensive design was completed within one year, and on-site construction was completed within two years. The UV disinfection system incorporated sustainable design features to reduce operating costs and power consumption, resulting in a smaller carbon footprint for the plant and less environmental impact generated by energy providers. A bio-retention "rain garden" catchment area was installed around the facility to reduce stormwater runoff and pollutants by infiltration and plant absorption. Originality and InnovationIEPA guidelines require a UV dosage of 40 millijoules (mJ)/cm2 to meet disinfection standards unless pilot testing is completed. The MWRD, Greeley and Hansen, and the UV manufacturer performed collimated beam testing for 12 months to evaluate the effluent treatment effectiveness of various UV dosages. The testing program demonstrated that a much lower dosage rate of 30 mJ/cm2 would effectively disinfect wastewater at the O'Brien WRP at all flows. As a result, a more energy-efficient seven-channel system was designed, eliminating $20 million in capital costs, while also reducing energy consumption and operating costs. The innovative UV system is designed to accommodate large variations in plant flow from 230 MGD to 450 MGD, with each of the seven channels capable of disinfecting up to 75 MGD. The low-pressure, high-output performance of the specialized UV lamps enables a high-capacity treatment volume. The UV channels, consisting of 896 high-intensity UV lamps configured as two 64-bulb banks per channel, can be independently activated or deactivated from service at power levels from 30% to 100% depending on wastewater characteristics, flow conditions, and WPR demand to maximize operational efficiency and minimize unnecessary power consumption. The unique system configuration features accessible equipment above the liquid level, instead of being submerged, enabling easy lamp replacement and system maintenance while the system remains in operation. ComplexityDesigning the largest wastewater UV disinfection system by flow capacity in the world was a challenging and complex project. The O'Brien WRP UV disinfection system required routing processed effluent flow from an 11-foot-by-11-foot conduit to the completed UV disinfection facility for treatment. Conveyed back into the conduit, disinfected effluent is discharged into the North Shore Channel. Design and construction complexities involved excavating and building concrete enclosures 40-feet below grade around this conduit at two different locations, and then breaking into the conduit at both locations to route the flow to and from the new UV disinfection facility, on a space constrained plant site. Construction of the concrete enclosures was largely completed while the plant was in full operation, with all work completed in advance of the core-drilling break-in procedure scheduled at the end of the sequence. Requiring special break-in plans and sequencing procedures, the WRP was removed from service for only eight hours when the main discharge pipe was temporarily shut down and dewatered. The discharge pipe was returned to operational service, with the flow immediately redirected to the UV disinfection facility, and routed back to the main effluent conduit. Sustainable Design and Environmental ImpactThe design of the O'Brien WRP UV system project involved provisions for meeting anticipated lower nitrogen and phosphorus limits for effluent water in the future. Provisions include plans for installing additional filters leading to the UV disinfection facility, and plans for locating and constructing a new 530-MGD pumping station at the O'Brien WRP site to handle anticipated future flow demand. Sustainable design features of the O'Brien WRP UV disinfection system enable lower energy consumption and operating costs, reduced environmental impact to the surrounding community, and less economic burden to ratepayers. Automatic intensity control of UV lights optimizes power consumption, and independently operated UV channels enables individual channels to be activated or deactivated as necessary to meet plant demand, or serviced or upgraded while remaining in operation. Quality and Accomplished GoalsThe $61.7 million O'Brien Plant UV System project achieved all expectations and goals of the MWRD. Initiated in April 2012 and operational in April 2016, the O'Brien WRP UV project demonstrates an integrated approach of collaborative design and construction for building the world's largest UV disinfection system by flow in a space-constrained plant location — without interrupting wastewater treatment operations or removing the WRP from service. In addition to meeting all MWRD operational requirements, the O'Brien WRP UV system project enabled the MWRD to fulfill commitments to the IEPA, local and state stakeholders, and environmental groups. The new UV system dramatically improves the quality of water throughout the Chicago Area Waterway System, protects the region's Lake Michigan drinking water supply, and improves long-term public safety for Chicago-area residents now and in the future. Click images to enlarge in separate window. Click here to return to the list of 2017 winners. |