- Home

- Contact Us

- News & Events

- Awards

- AAEES Awards Criteria

- 40 Under 40 Recognition Program

- Edward J.Cleary Award

- Excellence in Environmental Engineering and Science Education

- Gordon Maskew Fair Award

- Honorary Member

- International Honorary Member

- Ralph and Joe Bales Graber Science Award

- Stanley E. Kappe Award

- Environmental Communications Awards Competition

- Excellence in Environmental Engineering and Science Competition

- The AAEES Chapter Blue Marble Award

- Resources

- AAEES Microcredentials

- Annual Reports

- AAEES Press Releases

- AAEES Website How To VIdeos

- Environmental Engineer and Scientist

- Environmental Engineering Body of Knowledge

- PFAS Resources

- Specialty Examination Guide

- Students and Young Professionals Resources

- Who's Who in Environmental Engineering & Science®

- Leadership Opportunities

- Membership

- Donate

- Jobs

2017 Excellence in Environmental Engineering and Science® Awards Competition Winner

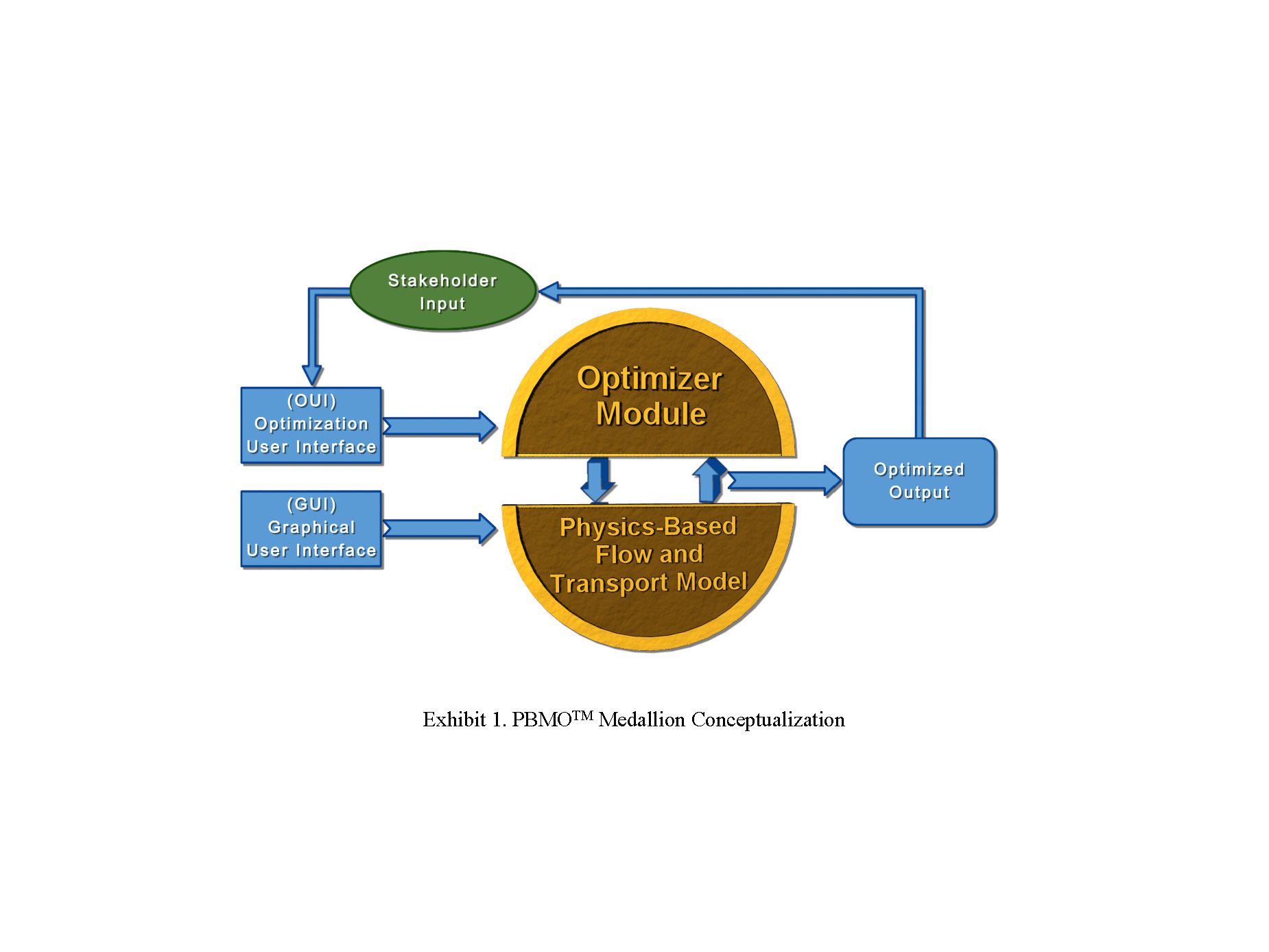

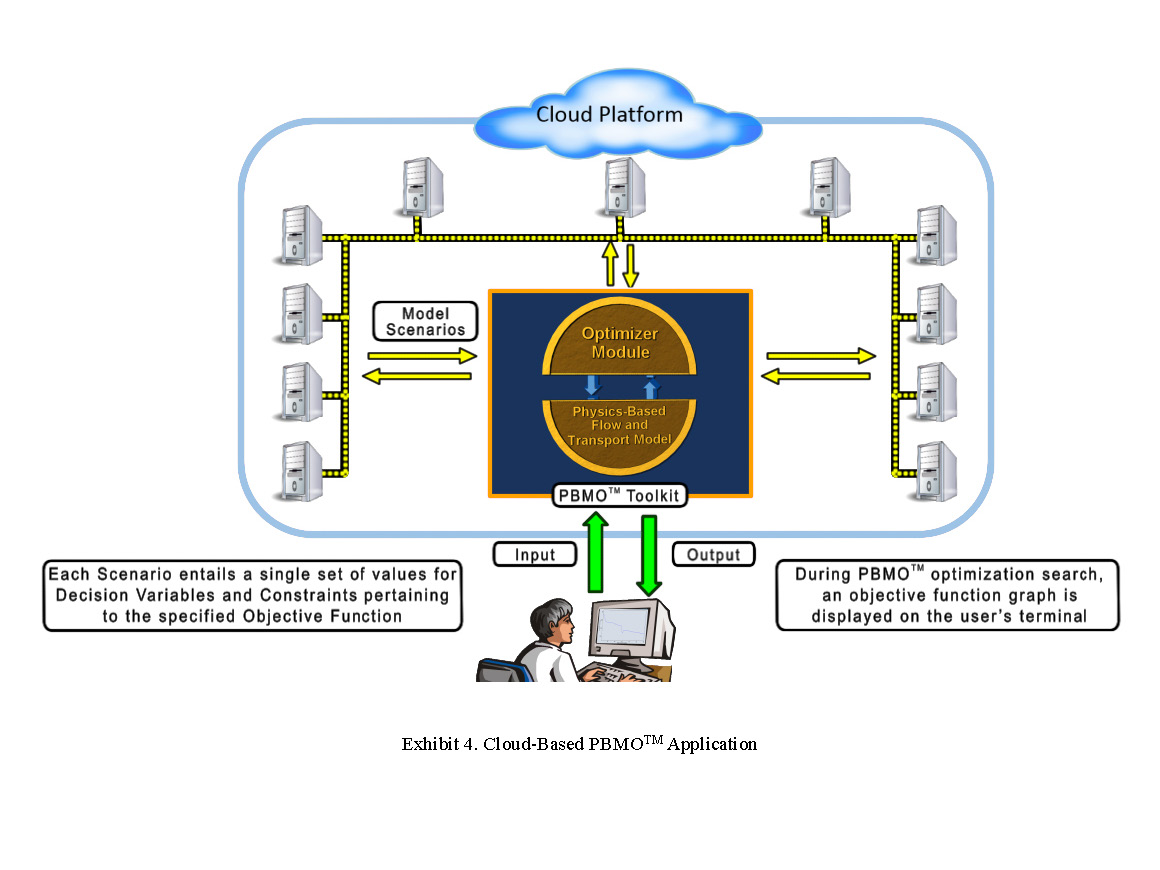

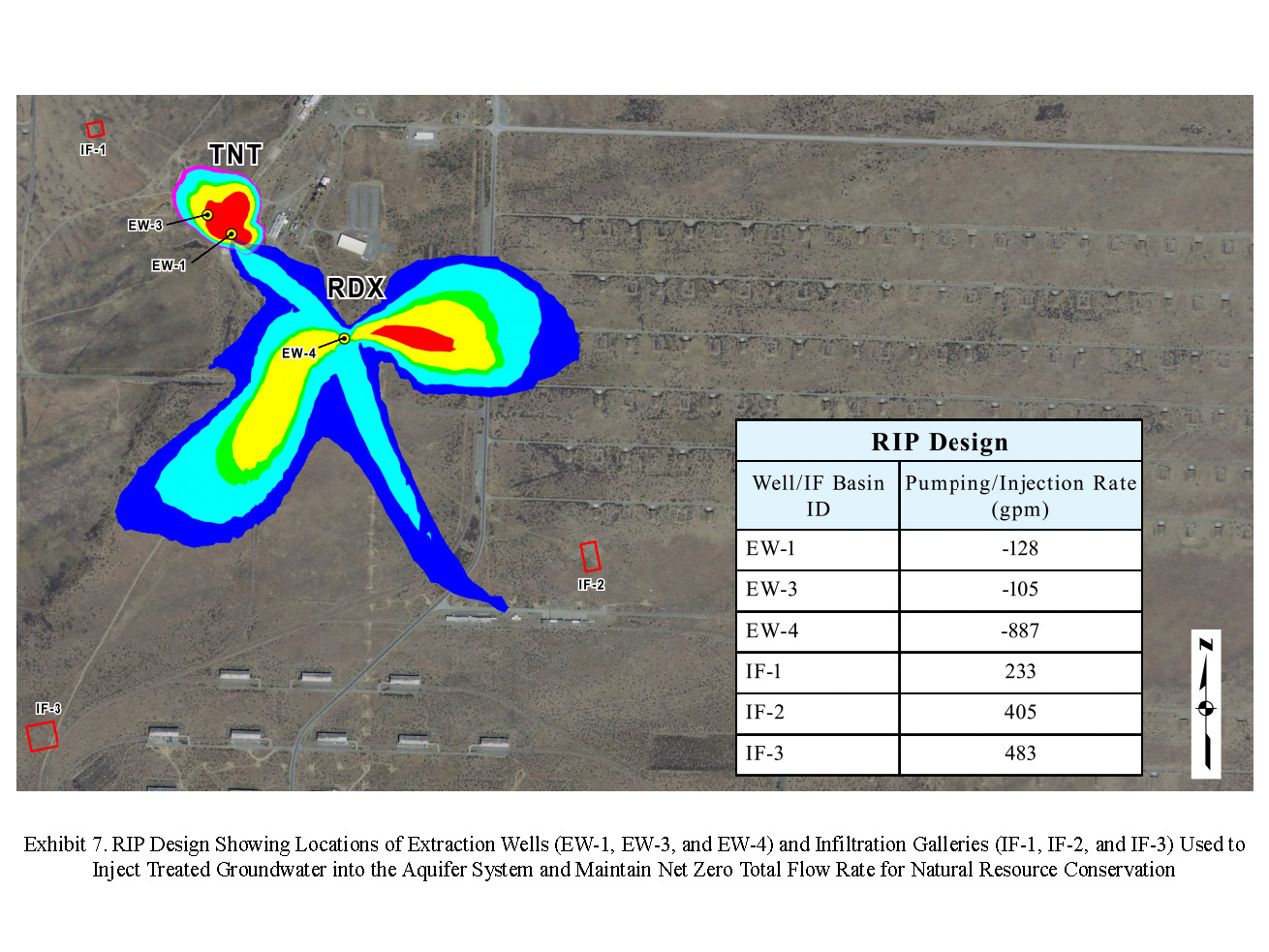

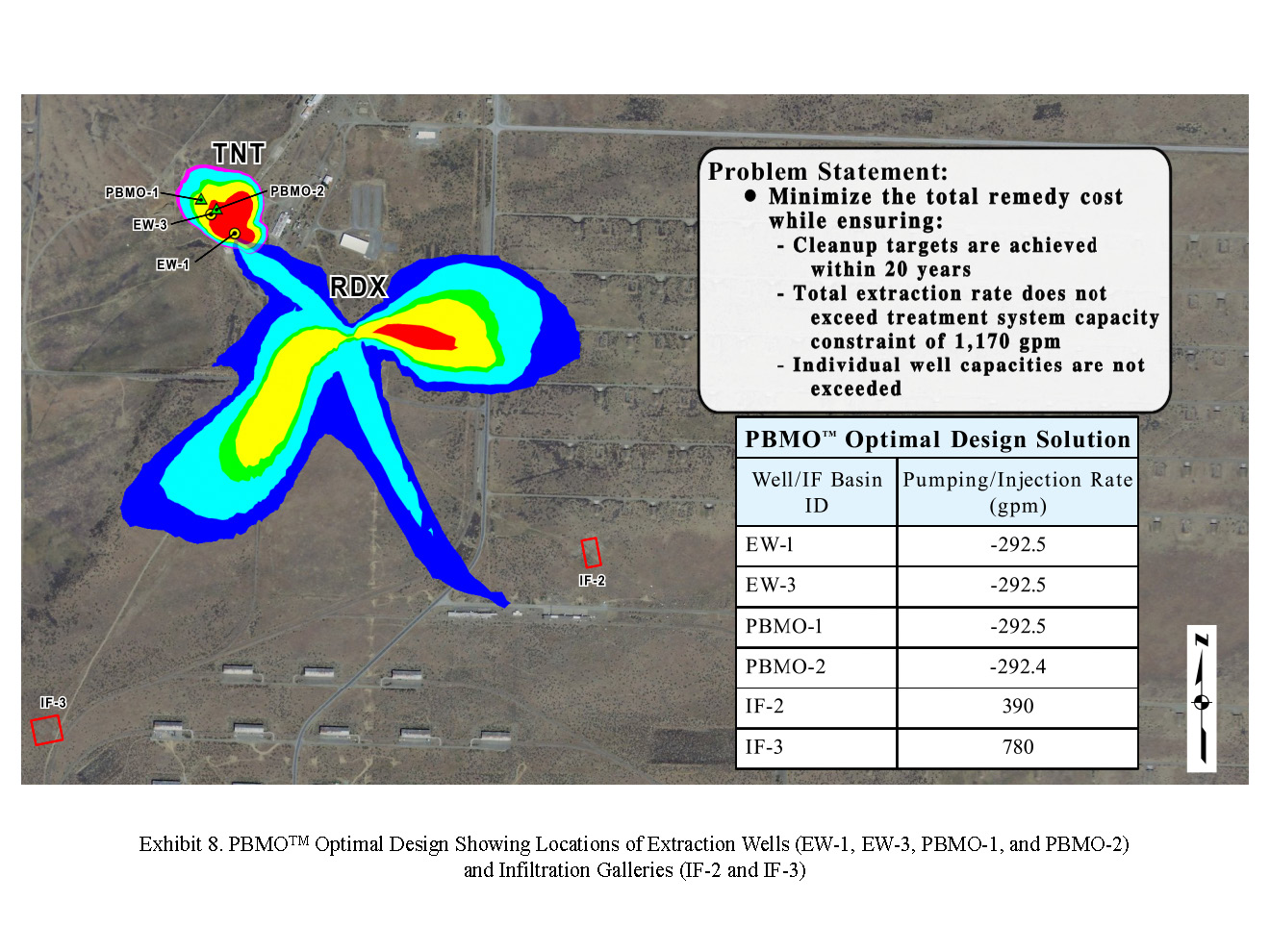

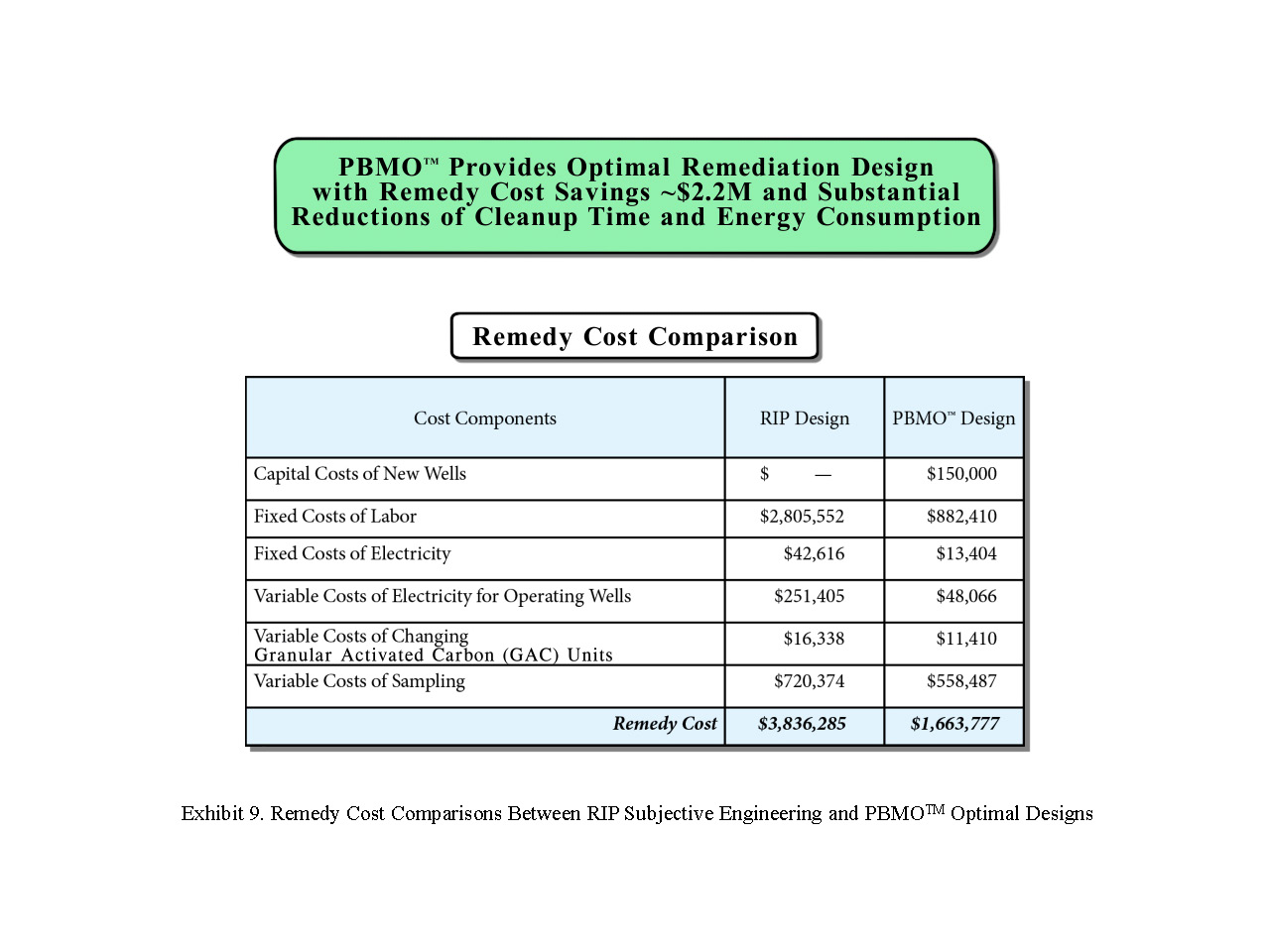

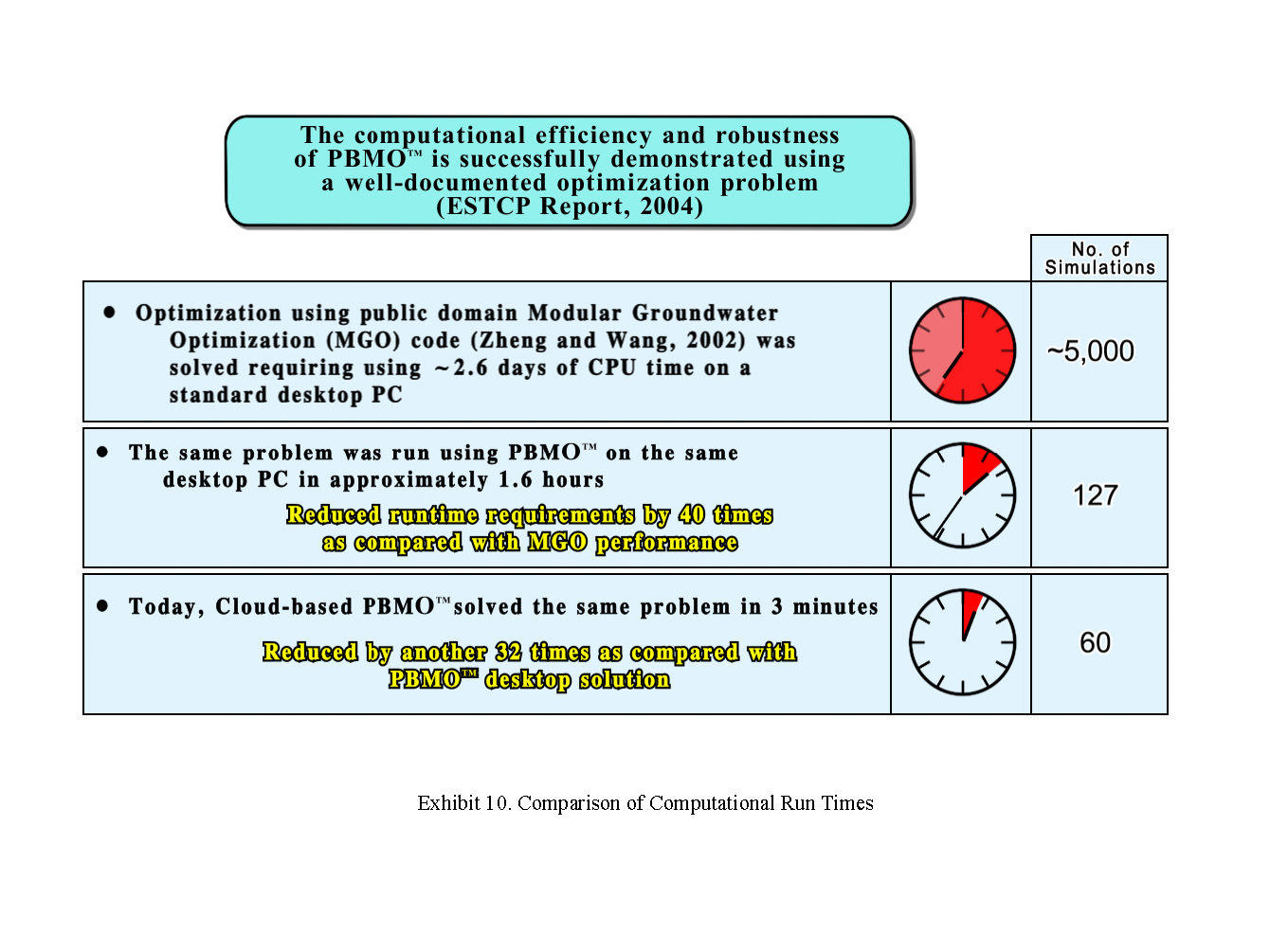

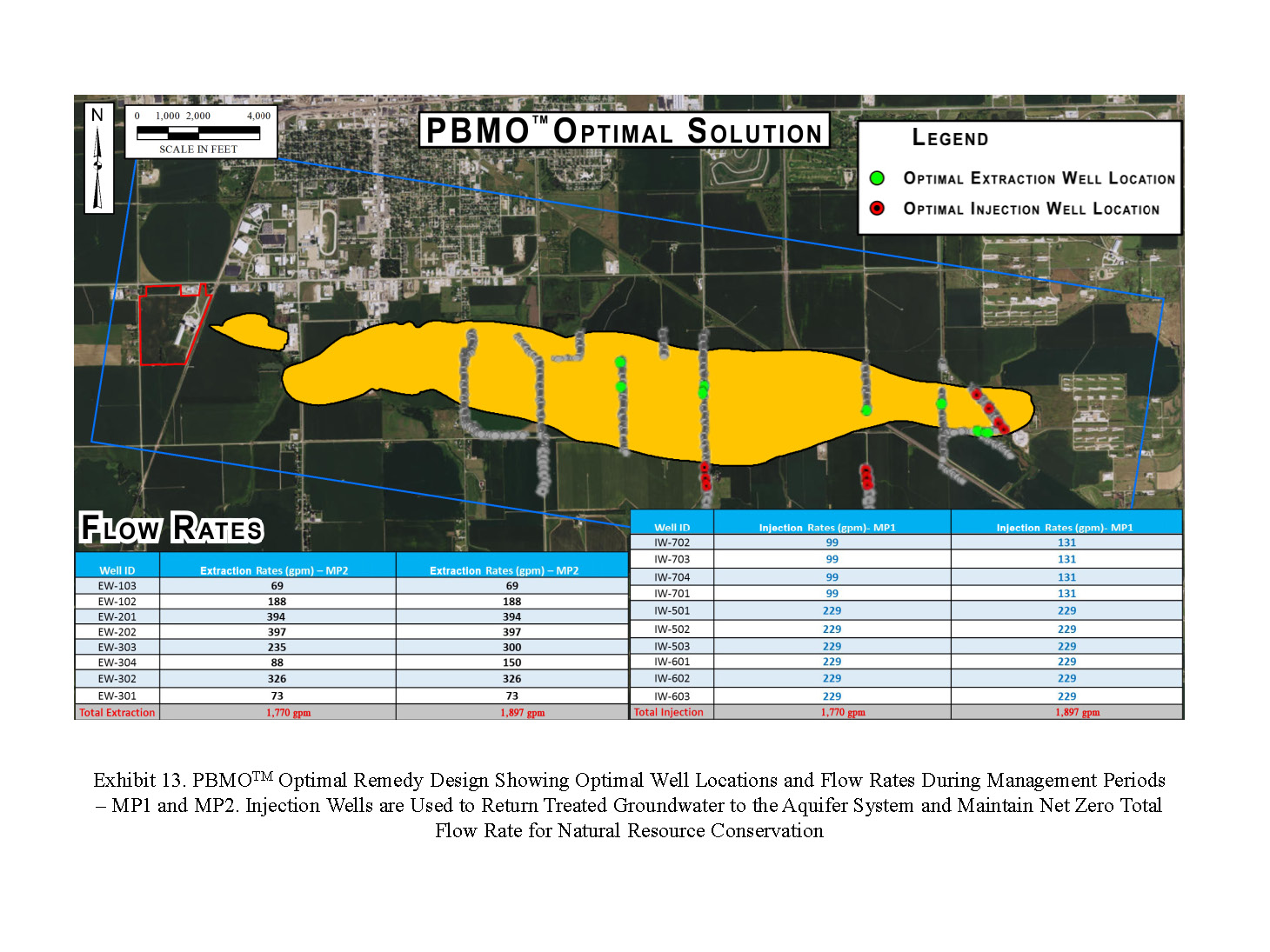

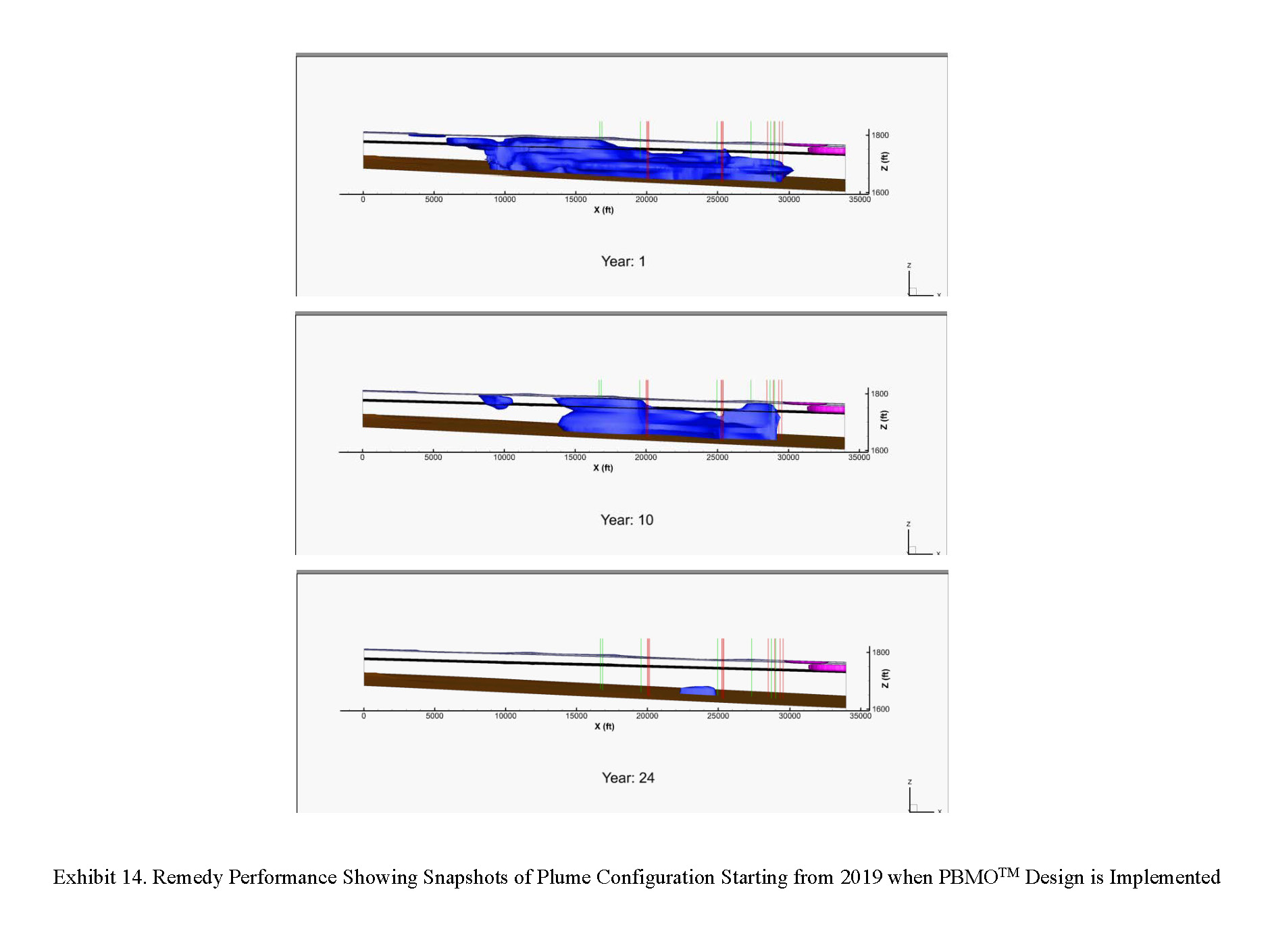

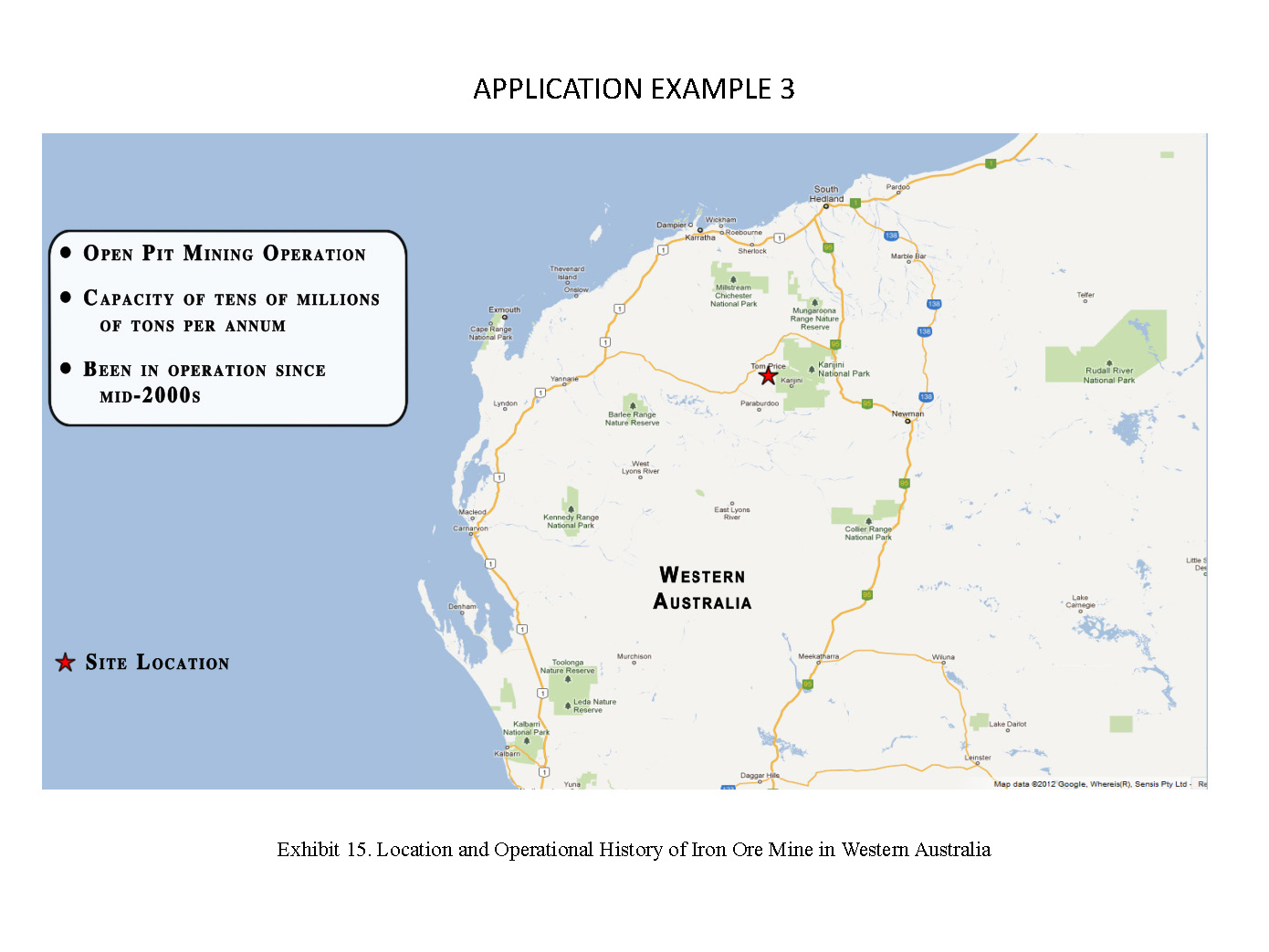

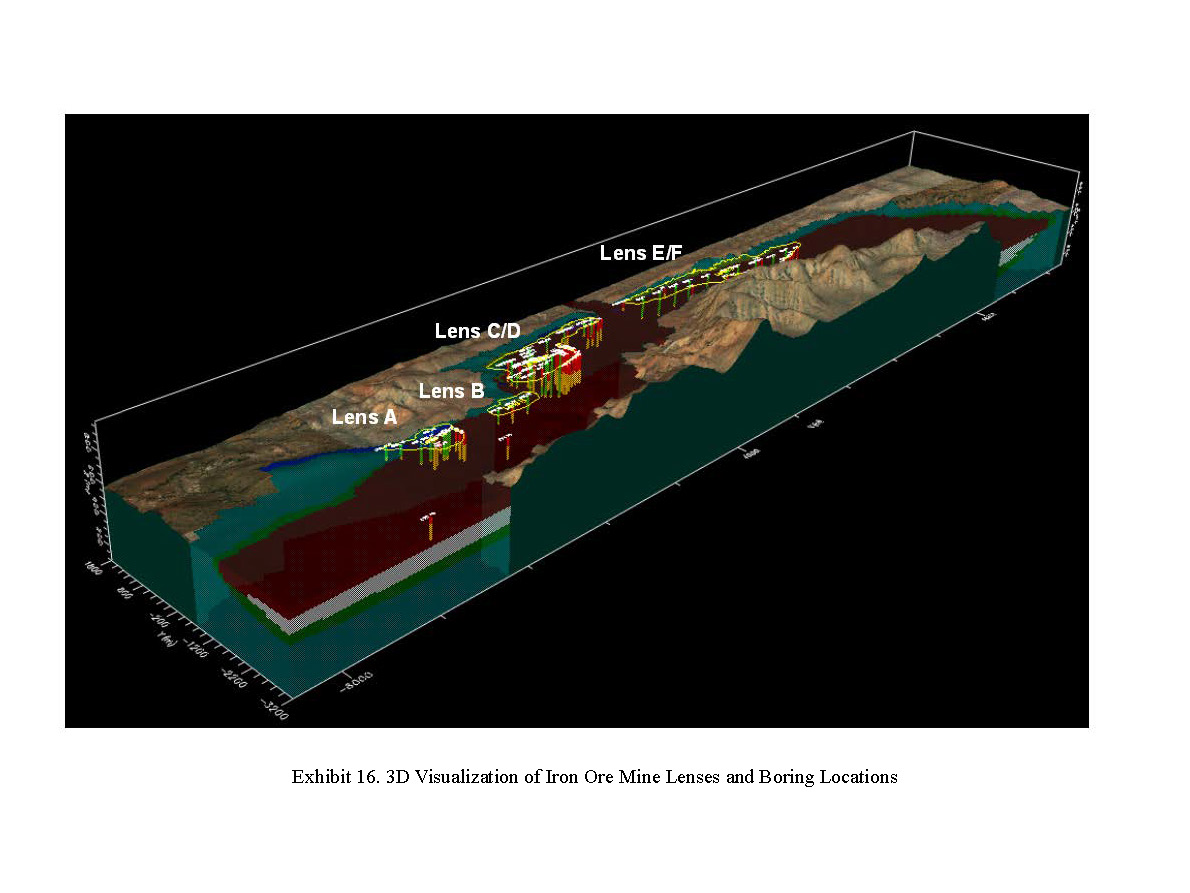

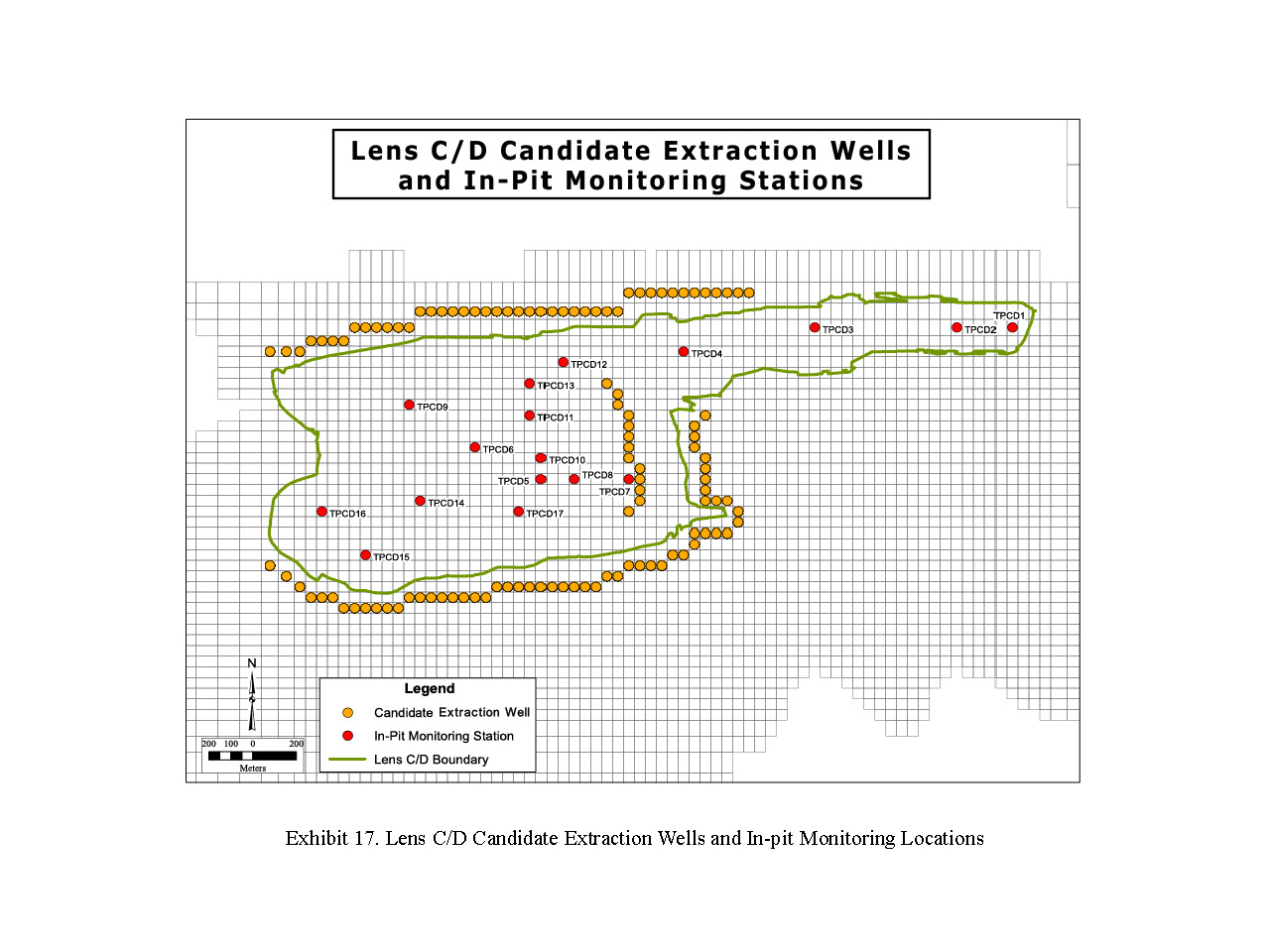

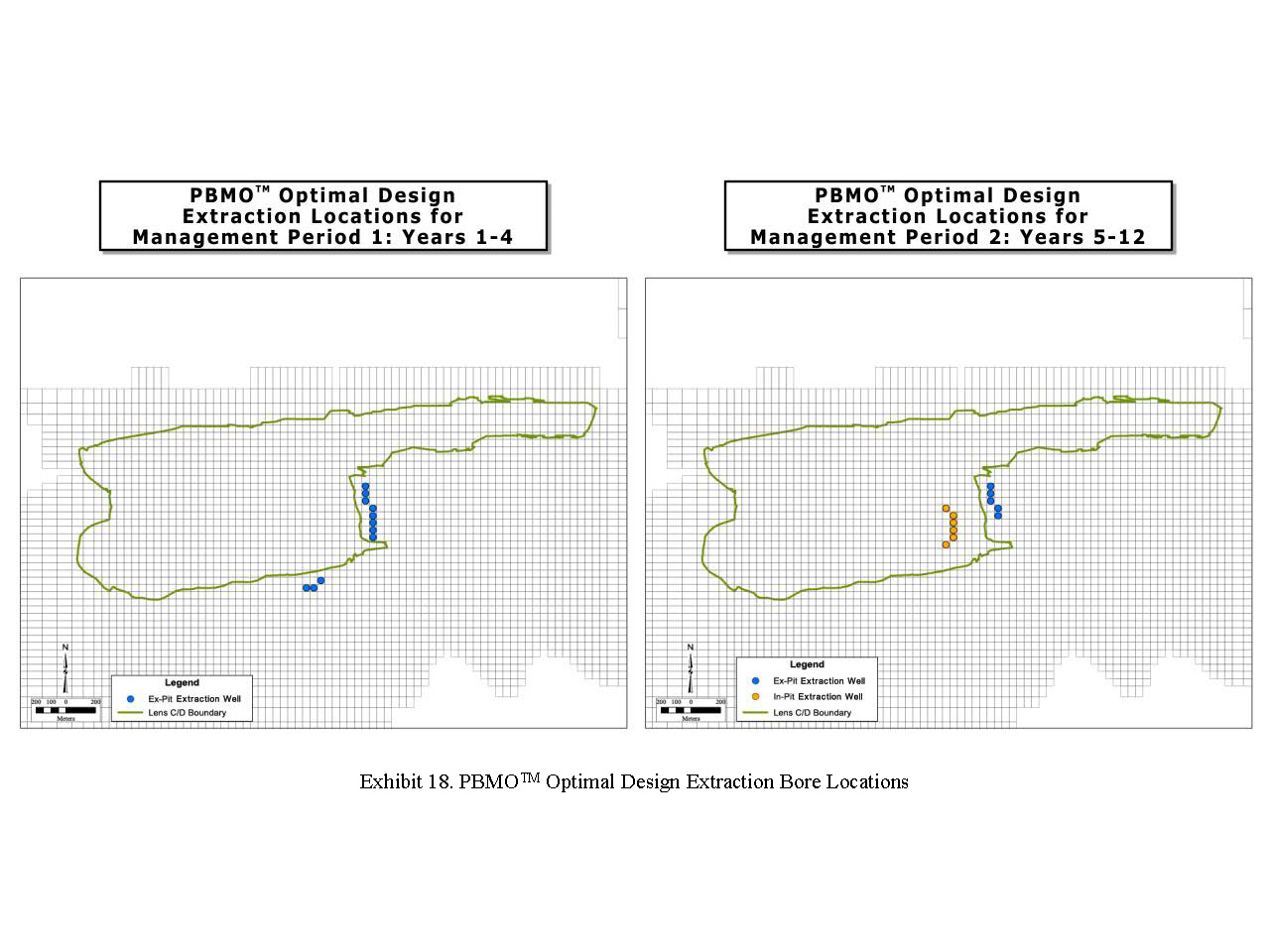

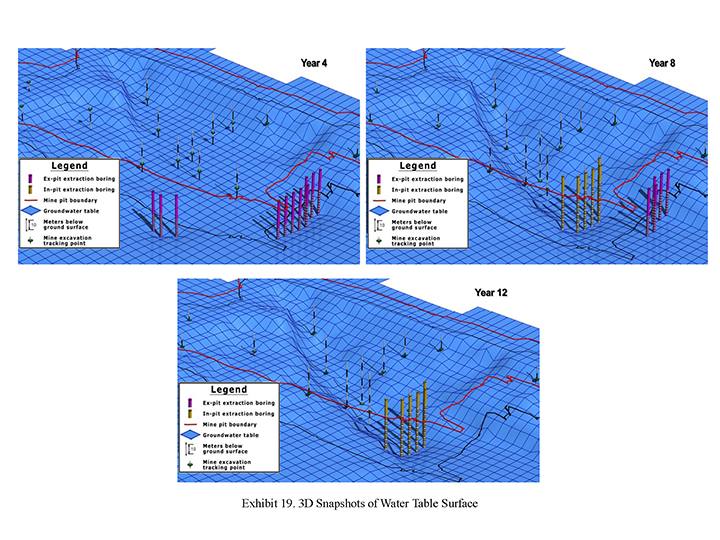

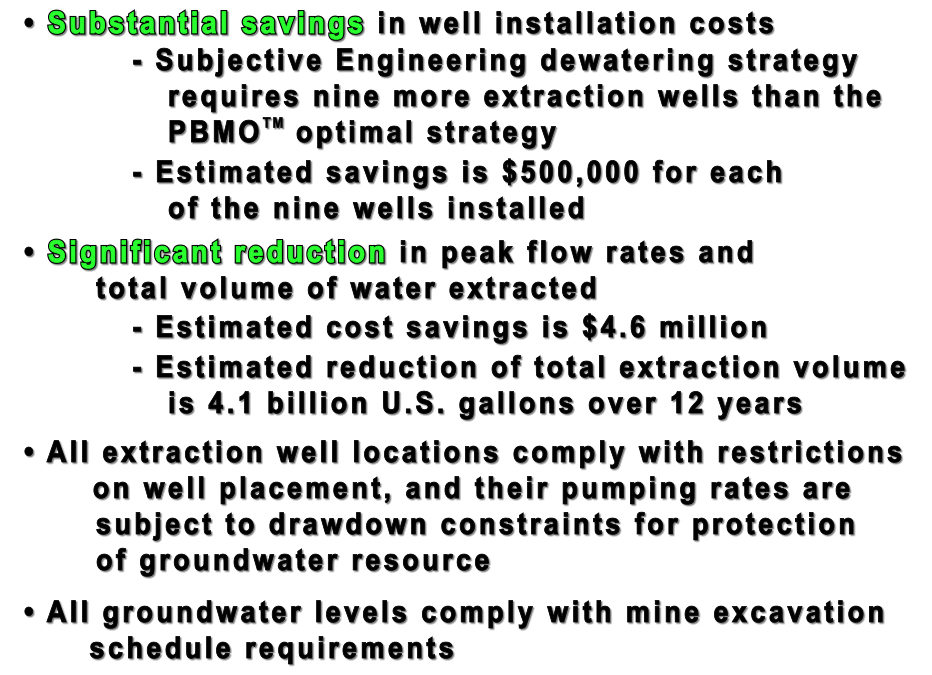

Grand Prize - ResearchPhysics-Based Management Optimization Technology for Supporting Environmental and Water Resource ManagementEntrant: HydroGeoLogic, Inc.  Entrant ProfileHydroGeoLogic, Inc. (HGL) is a prominent independent, employee-owned environmental engineering and water resources services firm. Established in 1987, HGL has over 300 employees and has earned a spot in Engineering News-Record's top 200 environmental firms rankings since 2006. HGL also conducts research and development (R&D) and has created cutting-edge software (MODFLOW-SURFACT® and MODHMS®) for integrated groundwater-surface water modeling. The software has been licensed for use in 50 countries. Over the past several years, HGL's R&D efforts have focused on linking formal numerical optimization techniques with physics-based flow and transport models, culminating in the development of Physics-Based Management Optimization (PBMO®) technology. PBMO® captures important site physics and financial constraints to produce optimal solutions that satisfy multiple competing objectives. Applied to environmental restoration, PBMO® identifies optimal remedy design and operation approaches that lead to timely and cost-effective cleanups. For water resource management, the tool balances water needs with resource protection. The technology has been configured to run on multi-core PCs in a cloud-based environment that allows it to solve large, complex environmental and water resources problems rapidly. PBMO® was developed for a wide range of applications. It can address remediation challenges with mass transfers between interconnected media and can reduce the environmental footprint of remedial systems by minimizing cleanup times and reducing capital and energy inputs. Benefits from PBMO® applications include reduction of potential human health risks, conservation of natural resources, realization of significant cost savings, timely attainment of cleanup goals, and facilitation of stakeholder consensus. Project DescriptionProblem StatementRemedial systems designed to restore contaminated environments to beneficial use are increasingly required to address multiple objectives. Engineered remedies must decontaminate or contain pollutants in complex media while minimizing factors such as cleanup time, cost and energy inputs, and secondary waste generation. Often remedial designs are constrained by surrounding property use, adjacent contamination, sensitive habitats, and regulatory requirements. While environmental simulation models can support remedial design, models alone cannot identify an optimal solution that balances multiple objectives, design options, and constraints. Computational optimization strategies provide robust mathematical frameworks to solve multi-objective problems; however, until recently, these algorithms, when coupled with site-specific models, have proved to be cumbersome, time-consuming, and expensive to implement. CPU time required to run even a limited number of simulations has been excessive (~days or weeks), thereby making use of computational optimization impractical for most environmental remediation problems. ApproachTo address these deficiencies, HydroGeoLogic, Inc. (HGL) has developed an integrated system called Physics-Based Management Optimization (PBMO®) that links environmental modeling with management optimization. The PBMO® tool identifies optimal remedial design and operational approaches that lead to timely and cost-effective cleanups. Applied to water resource management, the tool balances water extraction needs with resource protection. By linking modeling and computational optimization, PBMO® can realistically capture important site physics and financial constraints; achieve a coherent interpretation of disparate site data using all relevant information; and produce structured, credible solutions acceptable to stakeholders and regulators. PBMO® is conceptualized as a medallion with two interdependent and complementary halves. One half contains a module with calibrated physics-based, multimedia, flow, and transport models that seamlessly interacts with the optimization module in the other half. Examples of physics-based models frequently used to assist in remedial system design and operation include groundwater and integrated surface water/groundwater flow and transport models based on HGL's state-of-the-art codes such as MODFLOW-SURFACT® and MODHMS®. The optimization module consists of a collection of advanced optimization algorithms. Optimization is based on global optimization, which handles multimodal objective functions and strives to provide the best solution known as the "global optimum." Examples of advanced algorithms include the Lipschitz global optimization, branch and bound, and globally adaptive random search with machine learning. Data input/output in PBMO® is facilitated by graphical and optimization user interfaces. Software interfaces allow users to specify objective functions, decision variables, and constraints, and to enter site-specific data supporting the model. The cloud-based computational environment used in conjunction with highly efficient global search algorithms allows PBMO® to obtain solutions in a practical amount of time (a few minutes for small problems to a day for very large problems). Software interfaces also provide efficient visualization of optimization results. The PBMO® tool has provided optimized solutions to a variety of environmental remediation and water resource management problems. Presented here are three examples that highlight its capabilities: Example 1: Umatilla Army Depot, ORPBMO® was benchmarked against a well-documented problem involving minimization of the total life cycle cost of a pump-and-treat remedial system while accounting for possible remedy- in-place infrastructure expansions as well as operation and maintenance and sampling costs. The original solution, as reported in the literature, required ~5,000 model simulations and 2.6 days of run time on a desktop computer. Cloud-based PBMO® obtained an an improved optimal solution in 3 minutes with only 60 model simulations. The computational peformance breakthrough achieved by PBMO® technology is unprecedented! Example 2: Superfund Site, NEPBMO® was used to develop an optimal remedy design for a large chlorinated solvent plume. The problem involved minimizing total life cycle costs, including those for the initial remedy installation, operation and maintenance, and sampling. This problem was very large and complex, with 4,514 decision variables and over 2 million constraints. A flow and transport model with over one million grid cells was used to describe the contaminant migration through a complex aquifer system, and it represents one of the most challenging problems ever solved with an optimization software. PBMO® fostered communications among stakeholders. Initially, constraints specified by stakeholders were too stringent and yielded infeasible solutions. PBMO® was used to devise a modified set of contrainsts to identify a feasible region for optimization. With the final set of mutually agreed upon constraints, the optimal solution was obtained. Example 3: Iron Ore Mine, Western AustraliaPBMO® was used to design a dewatering strategy for two adjacent iron-ore lenses at an open- pit mine in Australia. The problem was complex, with 113 decision variables and 178 constraints. Additionally, the model used was a non-linear variably saturated flow model with over 200,000 grid cells. PBMO® yielded an optimal solution with estimated savings in well installation costs ($4.5M) and in water extraction costs ($4.6M). PBMO® was developed for a wide range of applications with a comprehensive, integrated approach. It is compatible not only with multimedia but also with multiphase flow and transport models. PBMO® is capable of handling remediation problems with mass transfers between interconnected media. It can reduce the environmental footprint of remedial systems by minimizing cleanup times and reducing capital and energy inputs, thus decreasing overall secondary waste generation. The innovation and originality of PBMO® is evidenced by the way it synergistically combines multimedia environmental modeling software with advanced optimization and efficient global search algorithms in a cloud-based computational environment. PBMO® was developed to be flexible and capable of handling environmental and water resource management problems of varying complexity. The complexity may include physical attributes, process-related aspects, or the procedural steps. Social and economic advancement resulting from PBMO® applications is reflected by a reduction of potential human-health risks, conservation of natural resources, realization of significant cost savings and timely attainment of cleanup goals, and facilitation of stakeholder consensus. The breadth of opportunity for application of PBMO® in addressing challenging environmental and water resource management problems is immense. The more complex the problem, the more value PBMO® provides in finding optimal solutions. The quality of PBMO® and its future potential are attested to by testimonials provided by two world-renowned subject matter experts. Click images to enlarge in separate window. Click here to return to the list of 2017 winners. |