- Home

- Contact Us

- News & Events

- Awards

- AAEES Awards Criteria

- 40 Under 40 Recognition Program

- Edward J.Cleary Award

- Excellence in Environmental Engineering and Science Education

- Gordon Maskew Fair Award

- Honorary Member

- International Honorary Member

- Ralph and Joe Bales Graber Science Award

- Stanley E. Kappe Award

- Environmental Communications Awards Competition

- Excellence in Environmental Engineering and Science Competition

- The AAEES Chapter Blue Marble Award

- Resources

- AAEES Microcredentials

- Annual Reports

- AAEES Press Releases

- AAEES Website How To VIdeos

- Environmental Engineer and Scientist

- Environmental Engineering Body of Knowledge

- PFAS Resources

- Specialty Examination Guide

- Students and Young Professionals Resources

- Who's Who in Environmental Engineering & Science®

- Leadership Opportunities

- Membership

- Donate

- Jobs

2017 Excellence in Environmental Engineering and Science® Awards Competition Winner

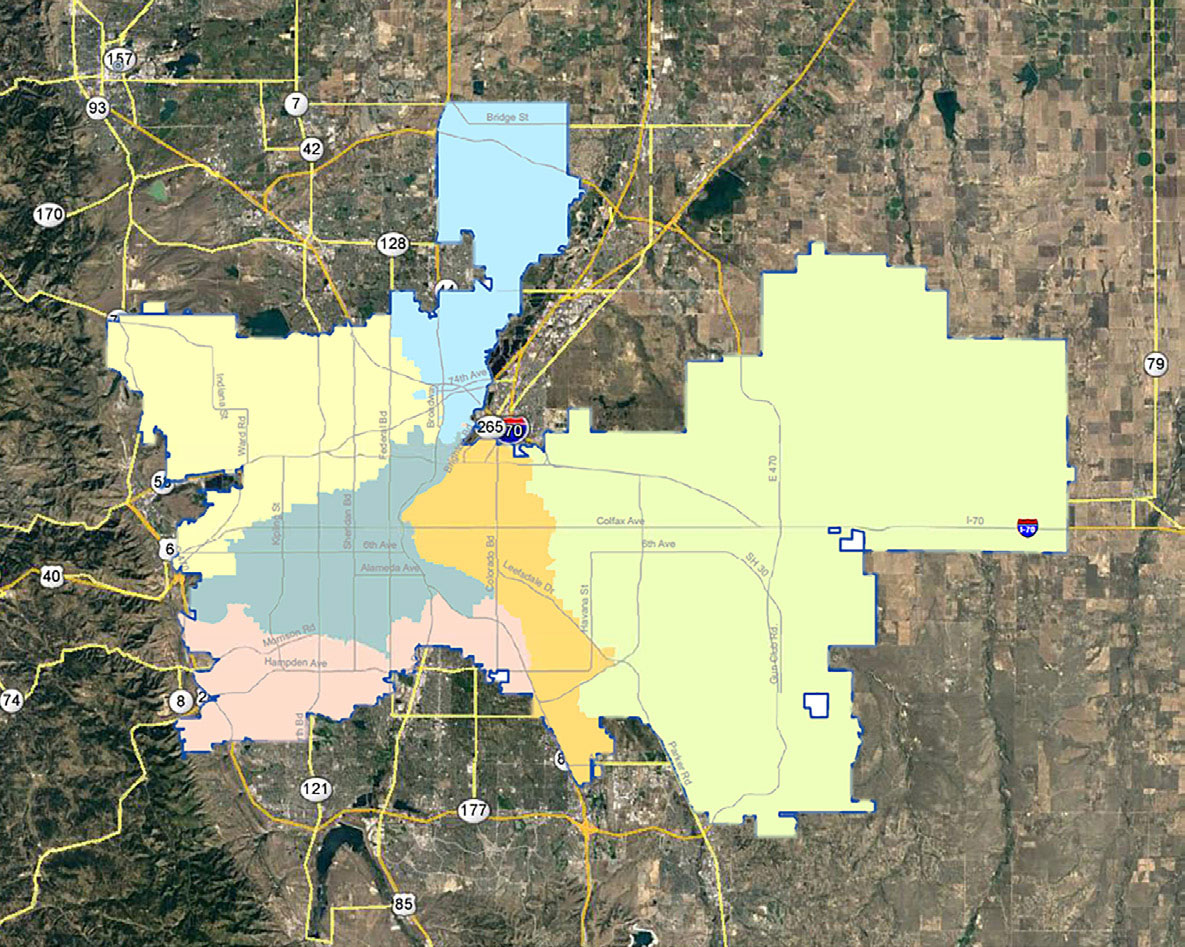

Grand Prize - DesignRobert W. Hite Treatment Facility South Secondary Improvements ProjectEntrant: Carollo Engineers, Inc.  Entrant ProfileMetro Wastewater Reclamation District (District) is comprised of 60 local governments providing wastewater services to about 1.8 million people in a 715-square-mile service area throughout greater Denver. The District currently handles 130 million gallons of wastewater each day (mgd) at the Robert W. Hite Treatment Facility (RWHTF). The RWHTF is the largest wastewater plant between the Mississippi River and the west coast, and is rated for a 220 mgd treatment capacity. Originally constructed in the mid 1960s, the RWHTF has under-gone several upgrades including the recent $151 million South Secondary Improvements Project that allows the entire plant to remove ammonia and nitrogen to below permitted discharge levels, and sets the District up for future phosphorus removal. More than 95 percent of the raw wastewater pollutants are removed at the RWHTF prior to discharge to the South Platte River. In 2016 the District commissioned the Northern Treatment Plant (NTP) located in Brighton, CO to provide 24 mgd of capacity for connectors northeast of Denver. The NTP uses advanced treatment prior to dis- charge to the South Platte River. The District's treated water makes up more than 85 percent of the South Platte River nine months of the year and is suitable for agriculture, fish and aquatic life, industrial use, water supply, and recreation. The District land applies stabilized biosolids at private farms and the District's METROGRO Farm. The award winning Resource Recovery and Reuse programs at the District serve as a national example of stewardship of our nation's agricultural and prairie lands.

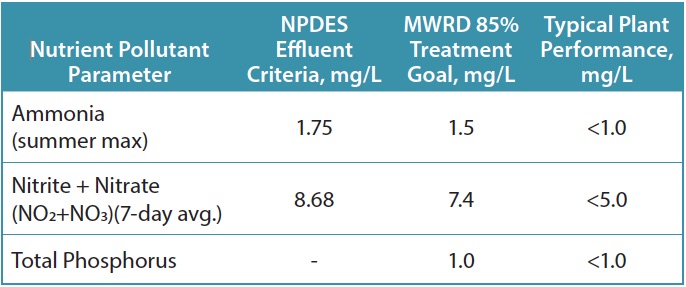

Project DescriptionThe Largest Operating Conversion of Pure Oxygen Activated Sludge to BNR in the USMetro Wastewater Reclamation District's (MWRD) 90-mgd High Purity Oxygen System (HiPOS), that provided nearly half of the 220-mgd capacity at the Robert W. Hite Treatment Facility (RWHTF), could not meet future nutrient limits. As a result, MWRD constructed a new South Aeration Complex (SAC) to treat 114-mgd to an effluent below 1.75 mg/L ammonia, 8.68 mg/L nitrogen (NO2+NO3), and prepare for future phosphorus (TP) limits. This $134 million construction project included:

Throughout the five-year construction duration, the existing plant remained in operation and compliant with discharge criteria.

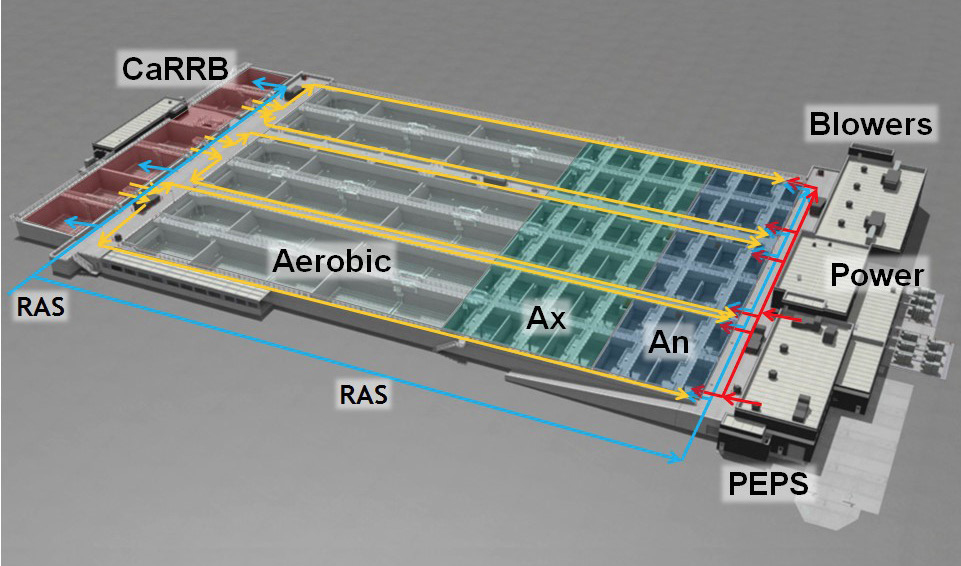

3D CADD image of the intergrated simple structure SAC, providing 114-mgd of BNR capacity including spacious piping and equipment galleries for safe O&M. "One Plant" Integrated ApproachFor decades, MWRD operated two different types of processes. This provided flexibility for effluent compliance but was difficult and costly to operate and maintain. This project created "one plant" with similar operations and maintenance (O&M) characteristics for simplified O&M. Construction costs were well under $1.50 per gallon. Savings were achieved by designing the SAC as one common, integrated structure larger than three football fields. PEPS, blower building, and electrical rooms were integrated into one multi-level West Mechanical Building. HiPOS basins were repurposed with new RAS/WAS pump stations. The existing clarifier capacity increased by 25 percent by integrating unique maze-type Energy Dissipating Inlets (EDIs). Integration Accomplishments

Quality, User Satisfaction, and PerformanceThe project provides low-cost BNR capacity, exceptional plant performance, operational flexibility, and logical layout for ease of O&M. MWRD Satisfaction and System Performance Accomplishments

Treated effluent quality is currently below the required nutrient discharge standards as indicated in the table below.

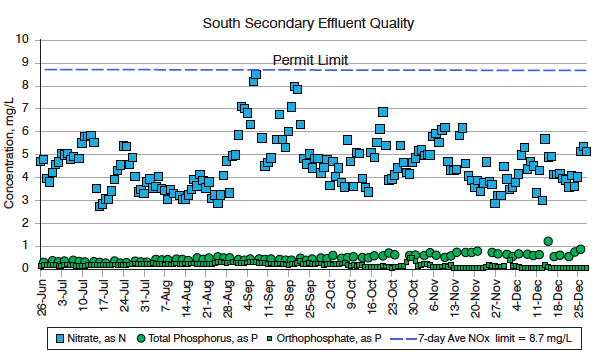

Figure 1 - Six months of data operating under A2O configuation resulted in effluent nitrate (Sec Eff NO3) ranging from about 3 to 8 mg/L and averaging less than 5 mg/L. Secondary effluent ortho phosphate (SE OP) and total phosphorus (SE TP) was consistently less than 1 mg/L.

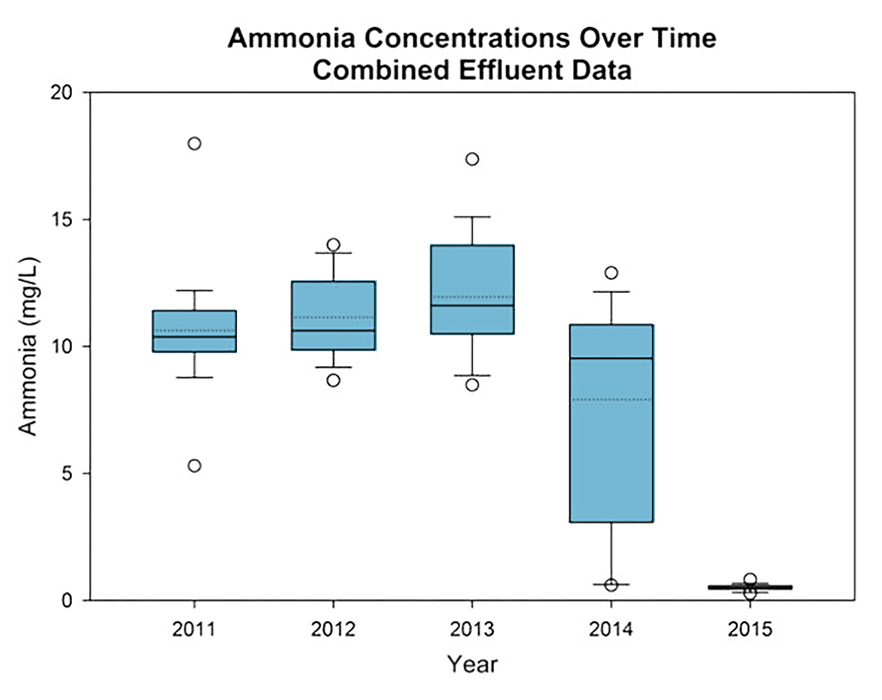

Figure 2 - Effluent ammonia prior to new plant startup ranged from 10 to 13 mg/L with significant variability. After full operation in 2015, the facility consistently achieved values of less than 1 mg/L.

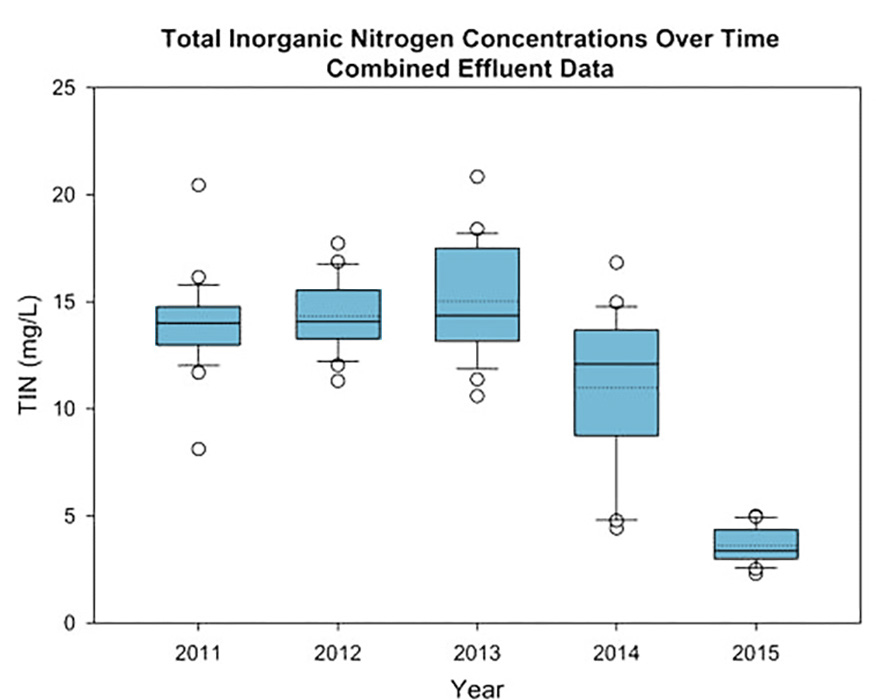

Figure 3 - Effluent total inorganic nitrogen (TIN) prior to new plant startup ranged from 13 to 17 mg/L with significant variability. After full operation in 2015, average TIN values were consistently under 5 mg/L.

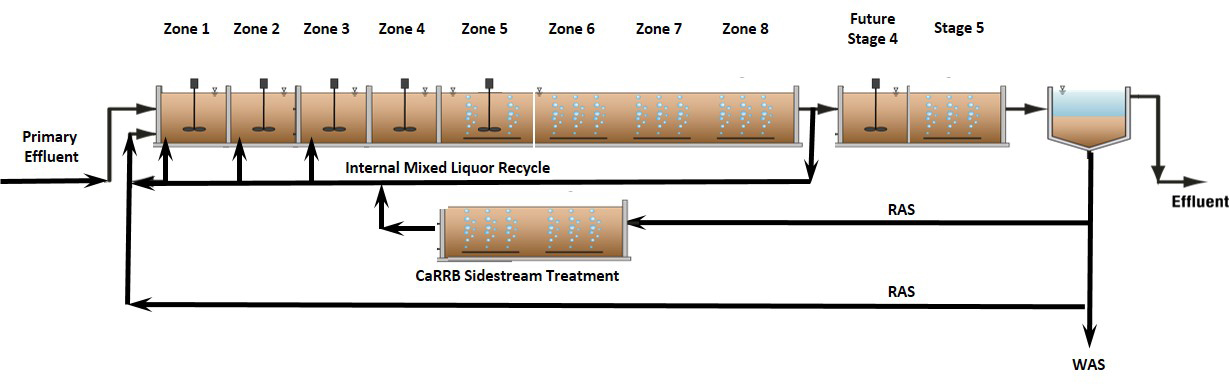

Figure 4 - Flexible aeration basin configuration allows MWRD staff to operation under a variety of modes optimizing performance and reducing treatment costs. The CaRRB sidestream treatment process provides reduction of ammonia and mainstream bioaugmentation for supercharged performance.

Rendering of interconnected SAC and modified existing HiPOS, clarifiers, and underground piping illustrates the project complexity. Effluent nitrogen and phosphorus are presented in Figure 1. Figures 2 and 3 illustrate before and after improvement for ammonia and nitrogen, respectively. The project reduced pollutant loadings to the South Platte River by over 4.0 million pounds per year. The BNR process provides a wide range of operating modes to meet changing operational goals and can be modified to 5-stage Bardenpho. Flexibility provides the operations staff with the ability to run in MLE, A2O, or other modes. The process illustrated in Figure 4 consists of four anaerobic/anoxic zones to manage nitrogen and phosphorus reduction, three larger aerobic zones for nitrification, and a "swing zone" that can operate anoxic or aerobic. CaRRB sidestream treatment reduces ammonia from dewatering and provides bioaugmentation to supercharge mainstream performance. Originality and InnovationThe project includes examples of new and innovative processes, and improvement of established engineering procedures to create one of a kind originality. Key Accomplishments in Innovation and OriginalityTreatment Process

Structural Design

Mechanical Equipment

Electrical Gear

ComplexityThe size of the new South Secondary Complex alone required complex engineering solutions. Notable Project Complexities:

Large, complex basins and equipment incorporated into the project:

Final tie-ins and startup used a complex temporary bypass pumping system. The 128-mgd pumps were staffed 24/7 and operated continuously for six months. Social and Economic AdvancementAt a unit cost of under $1.50 per gallon, the project was completed significantly below the national average cost for secondary treatment, which ranges from $2 to $4 per gallon. Innovations such as CaRRB sidestream treatment, anti-foam trapping baffle walls, axial flow dry pit MLR pumps adapted from the power industry, and single structure design serve as a model to help others reduce construction costs and improve O&M. Managing treatment costs reduces user fees for ratepayers contributing to economic sustainability. The elimination of more than 4.0 million pounds of nitrogen discharge to the South Platte River and provision for future phosphorus removal protects receiving waters, improves aquatic habitat, and reduces impacts on lakes and reservoirs used for downstream water supply. Click images to enlarge in separate window. Click here to return to the list of 2017 winners. |