- Home

- Contact Us

- News & Events

- Awards

- AAEES Awards Criteria

- 40 Under 40 Recognition Program

- Edward J.Cleary Award

- Excellence in Environmental Engineering and Science Education

- Gordon Maskew Fair Award

- Honorary Member

- International Honorary Member

- Ralph and Joe Bales Graber Science Award

- Stanley E. Kappe Award

- Environmental Communications Awards Competition

- Excellence in Environmental Engineering and Science Competition

- The AAEES Chapter Blue Marble Award

- Resources

- AAEES Microcredentials

- Annual Reports

- AAEES Press Releases

- AAEES Website How To VIdeos

- Environmental Engineer and Scientist

- Environmental Engineering Body of Knowledge

- PFAS Resources

- Specialty Examination Guide

- Students and Young Professionals Resources

- Who's Who in Environmental Engineering & Science®

- Leadership Opportunities

- Membership

- Donate

- Jobs

2022 Excellence in Environmental Engineering and Science® Awards Competition Winner

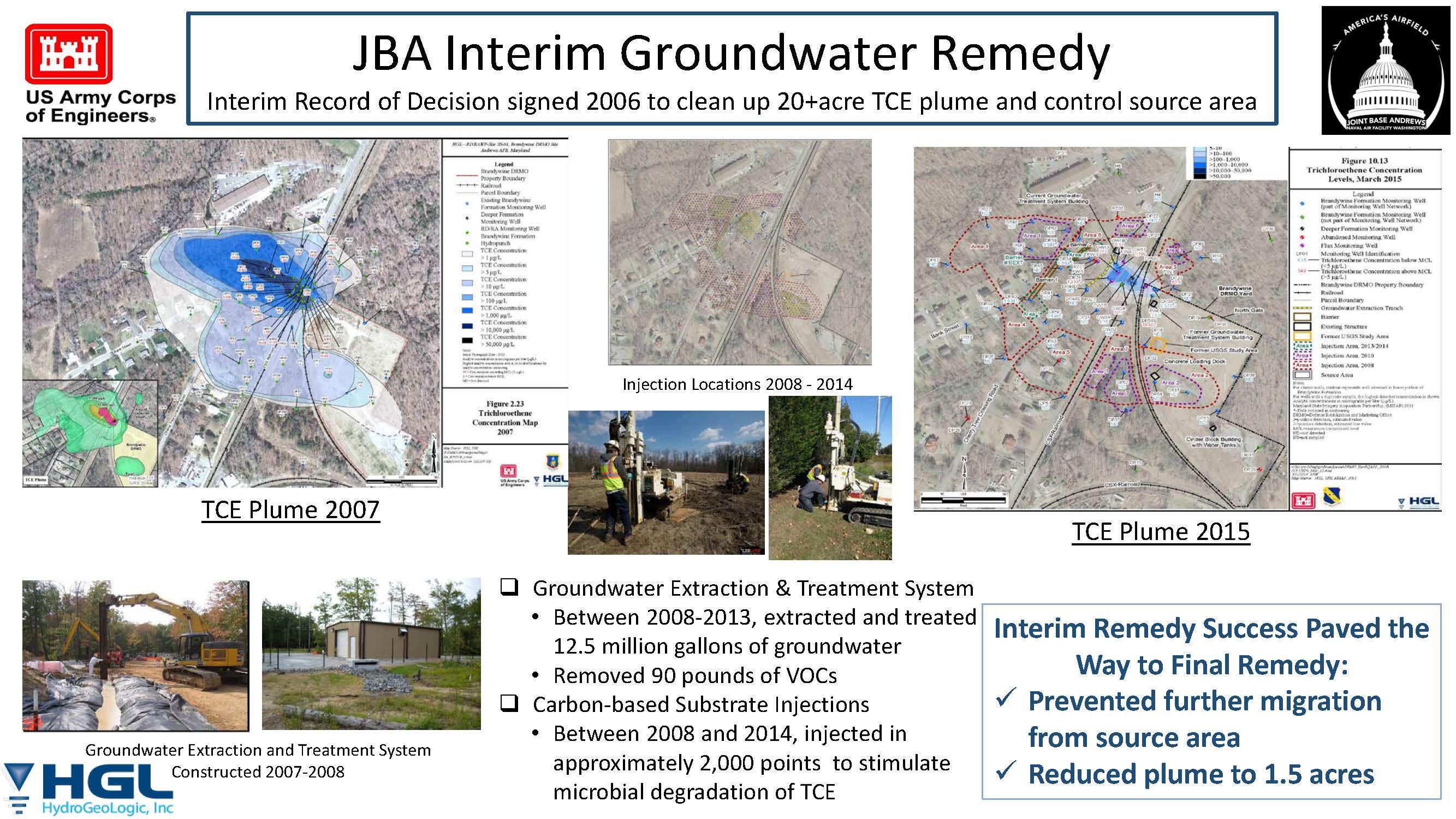

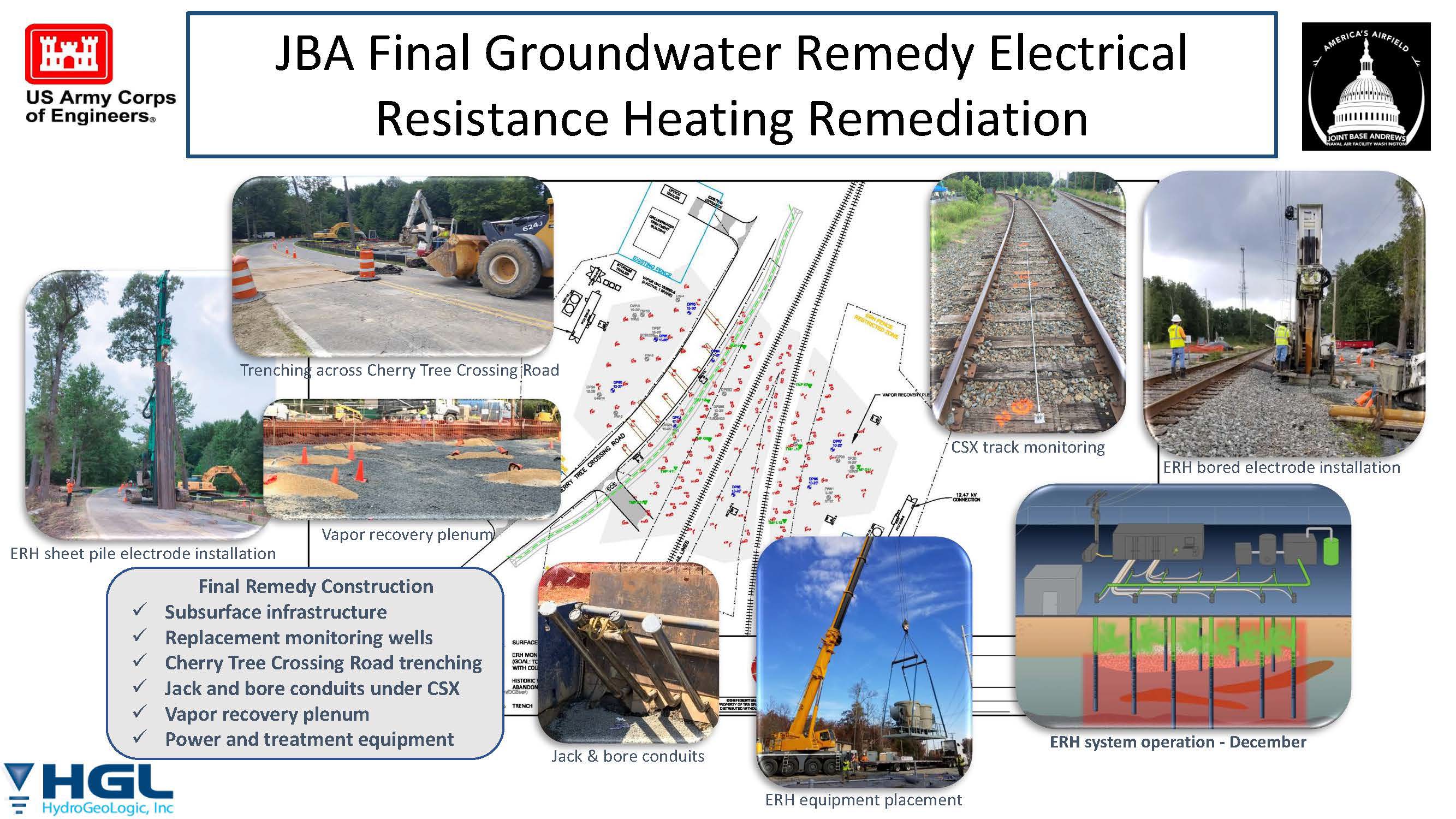

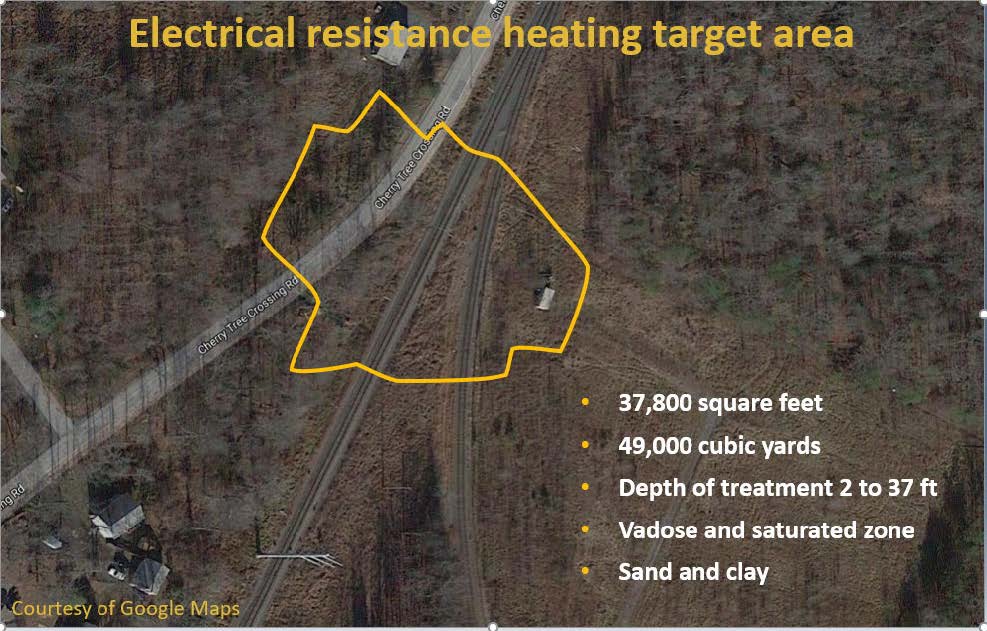

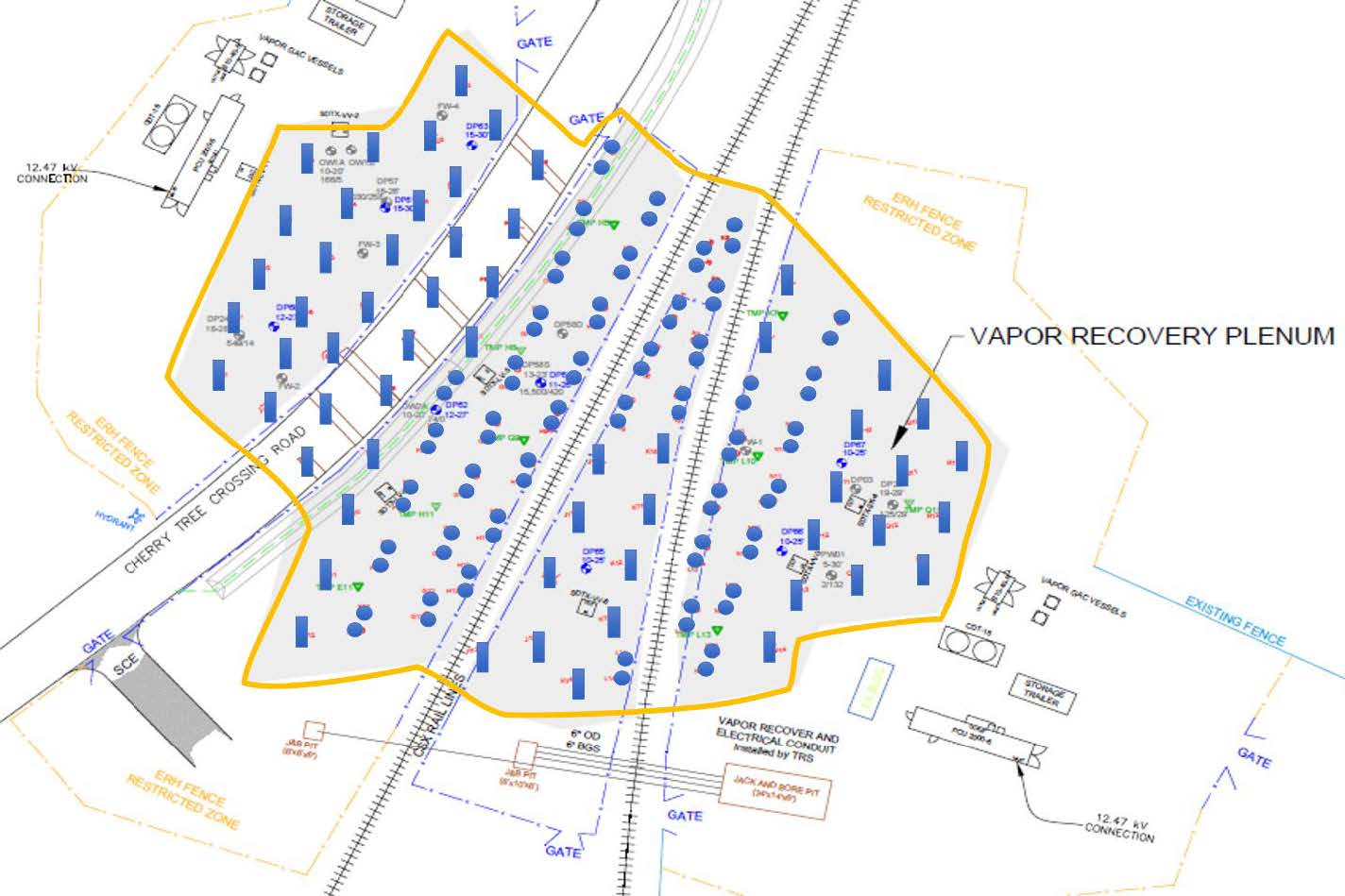

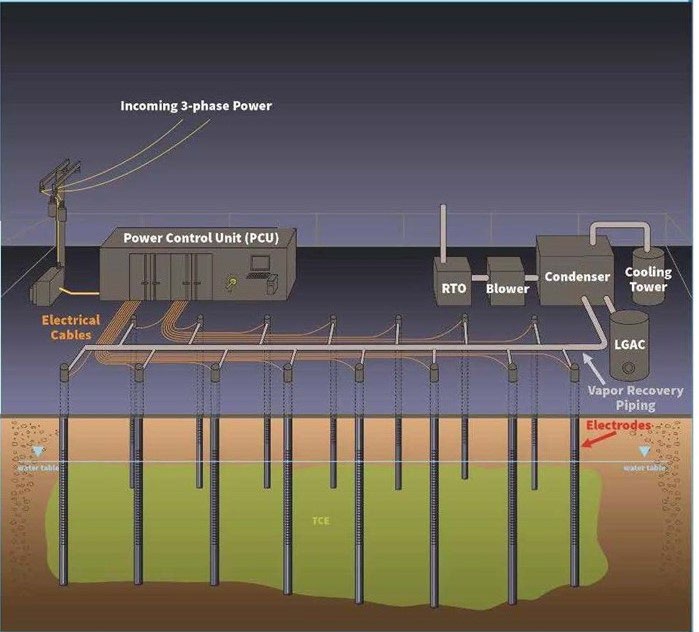

Superior AchievementCategory Entered: Industrial Waste PracticeInnovative Use of In Situ Treatment Technologies at Joint Base AndrewsEntrant: HydroGeoLogic, Inc. Entrant Profile Entrant ProfileHydroGeoLogic, Inc. (HGL) is a nationally prominent independent, employee-owned environmental engineering and water resource services firm. Established in 1987 and now with nearly 500 employees, HGL has extensive experience providing hazardous waste site characterization, remedy design, construction, operation and maintenance, optimization, mine reclamation, and munitions response services. The Engineering News-Record has listed HGL as one of the top 200 environmental firms since 2001. HGL has supported the U.S. Environmental Protection Agency (EPA), branches of the Department of Defense (DoD), the Department of Interior, and the Department of Energy (DOE) under several full-service remediation contracts. HGL has received numerous “Very Good” and “Exceptional” U.S. Government Contractor Performance Assessment Reporting System (CPARS) ratings from its DoD and EPA clients. Joint Base Andrews (JBA) is a high-profile U.S. military facility in Maryland and the home of Air Force One. As prime contractor, HGL remediated a 21-acre trichloroethene (TCE) plume in groundwater extending from the JBA-controlled former Brandywine Defense Reutilization and Marketing Office (DRMO) yard into an adjacent residential area, with a railroad, a public road, and water and sewer utilities crossing the site. Work was conducted under multiple contracts with the U.S. Army Corps of Engineers. Multiple remedial technologies were employed including the innovative electrical resistance heating thermal in situ remediation with soil vapor recovery and an extensive in situ enhanced reductive dechlorination remedy. The project met/exceeded established remedial goals, and HGL received “Exceptional” interim and final CPARS ratings in all categories for this work. Project DescriptionJoint Base Andrews (JBA) is a high-profile military facility in Maryland and the home of Air Force One. As prime contractor, HGL remediated a 21-acre trichloroethene (TCE) plume in groundwater extending from the JBA-controlled former Brandywine Defense Reutilization and Marketing Office (DRMO) beneath active railroad tracks owned by CSX Transportation (CSX) into an adjacent residential area. Work was conducted under multiple contracts with the U.S. Army Corps of Engineers. Site features complicating HGL’s characterization and remediation efforts included complex geology with interbedded low permeability geologic units, a suspected paleochannel, and an underlying aquitard that influenced plume migration and remained the primary source of contamination via matrix diffusion. This complex project addressed a dense nonaqueous phase liquid (DNAPL) source area and a dissolved chlorinated volatile organic compound (cVOC) plume in a busy residential area, with a railroad, public road, and water and sewer utilities crossing the site. HGL used a comprehensive integrated approach that considered multiple environmental media (including water, soil, and air) and involved review and application of multiple in situ treatment technologies. HGL managed communication among numerous stakeholders, fostering open communication and transparency, including speaking regularly at civic association meetings and establishing a toll.free number to respond to citizen concerns. HGL developed productive relationships with the client and regulatory agencies by providing comprehensive and credible presentations to convey information and justify site strategies. This collaborative relationship allowed HGL to manage expectations effectively and mitigate critical site issues. For example, HGL met with the Washington Suburban Sanitation Commission to resolve issues with utility re-routes and with CSX to corroborate Federal Railroad Administration track monitoring requirements. For the interim remedy, HGL designed, constructed, and operated a groundwater extraction and treatment system (GETS) to achieve hydraulic control of the DNAPL source area. In addition, HGL designed and executed an extensive in situ enhanced reductive dechlorination remedy that included injection of carbon substrate mixed with zero-valent iron (ZVI) in select areas to support biological reductive dechlorination, aquifer buffering using sodium bicarbonate to neutralize the naturally acidic groundwater to the optimum pH range, and bioaugmentation to provide the requisite microbial community. In residential areas, HGL used gravity-fed amendment injection to provide amendment distribution while limiting the need to work on private property. As part of the project’s initiative to promote the health of the public and environment, HGL installed methane detectors in the residences to confirm that methane produced by fermentation of the carbon substrate did not intrude into the homes. As part of this innovative project, which represented the first original in situ thermal treatment project completed under an active railway, HGL worked with CSX to install electrodes within its right-of-way. HGL remediated the entire plume beneath the residential area to U.S. Environmental Protection Agency Maximum Contaminant Levels (MCLs). After 4 years of GETS operation, it became evident that contaminants from an off-site plume had migrated into the area of influence of the hydraulic capture zone. To prevent comingling of this contamination with the Brandywine site plume, HGL shut down the GETS. In the absence of hydraulic control of the source area, HGL injected oil/lactate/ZVI-based substrate in a permeable reactive barrier configuration to arrest plume migration. Continued monitoring demonstrated that the barrier remained viable while the remedial design for the final remedy was completed, with no contaminant breakthrough during the 6-year site remediation period. For the final remedy, HGL oversaw the design, construction, and operation by its thermal remediation partner, TRS Group, of a large-scale electrical resistance heating (ERH) system to address high-mass residual DNAPL sources within the underlying aquitard and a shallow source of 1,4-dichlorobenzene (1,4-DCB). The thermal treatment volume was 49,000 cubic yards, bisected by a public road, water and sewer utilities, and railroad tracks. CSX required the ERH system to incorporate real-time monitoring of the two rail lines to rapidly identify any track movement within the tolerances specified in Federal Railroad Administration regulations. To accomplish this, HGL installed an Automated Motorized Total Station and survey prism system that used a laser to measure movement of mirror survey prisms mounted on the steel rail of the tracks multiple times each day during the operational period. This large-scale ERH system successfully removed the DNAPL source located in a low permeable layer 30 to 40 ft below ground surface. The ERH system employed two electrode designs: sheet pile electrodes were installed at 58 locations and bored electrode pairs were installed at 43 locations within the treatment area. Seventeen temperature monitoring points were installed to monitor soil temperatures. Conduits were installed under the CSX rail lines using CSX-mandated drilling methods. Surface construction included placement of a gravel vapor plenum with vapor recovery (VR) screens, installation of a 20-mil liner atop the ERH treatment areas, installation of the VR system manifolds; and connection of all power cables and data communication lines to ERH equipment and field control boxes. ERH equipment included two power control units, two steam condensers and cooling towers, two VR vacuum blowers, vapor-phase granular activated carbon vessels for the vapor extraction system, and seven step-down transformers. HGL operated the ERH system for 206 days, for a total of 277 kWh per cubic yard applied. Operational parameters, including power application throughout the treatment volume, subsurface temperatures, subsurface vacuum, condensate production, VR flows/pressures, and estimates of cVOC concentrations in the recovered subsurface vapors were measured routinely. When progress toward achieving MCLs appeared to stall at three wells. HGL worked with the ERH vendor to increase power delivery to these areas and instituted more frequent sampling to assess progress and optimize power delivery. The quality (Criterion 2) of the response was exhibited by the results: ERH treatment reduced TCE levels 97.2% and 1,4-DCB levels 99.5%, with 1,700 pounds of total contaminant mass removed. The project was selected by the DCHWS symposium committee for presentation at the April 2019 Successful Applications for Thermal Treatment panel (https://www.same.org/Portals/0/posts/philadelphia/documents/DCHWS/DCHWS2019/DCHWS 2019_P3S2.pdf). HGL received “Exceptional” U.S. Government Contractor Performance Assessment Reporting System (CPARS) ratings in all categories for this work. Click images to enlarge in separate window. Click here to return to the list of 2022 winners. |