- Home

- Contact Us

- News & Events

- Awards

- AAEES Awards Criteria

- 40 Under 40 Recognition Program

- Edward J.Cleary Award

- Excellence in Environmental Engineering and Science Education

- Gordon Maskew Fair Award

- Honorary Member

- International Honorary Member

- Ralph and Joe Bales Graber Science Award

- Stanley E. Kappe Award

- Environmental Communications Awards Competition

- Excellence in Environmental Engineering and Science Competition

- The AAEES Chapter Blue Marble Award

- Resources

- AAEES Microcredentials

- Annual Reports

- AAEES Press Releases

- AAEES Website How To VIdeos

- Environmental Engineer and Scientist

- Environmental Engineering Body of Knowledge

- PFAS Resources

- Specialty Examination Guide

- Students and Young Professionals Resources

- Who's Who in Environmental Engineering & Science®

- Leadership Opportunities

- Membership

- Donate

- Jobs

2022 Excellence in Environmental Engineering and Science® Awards Competition Winner

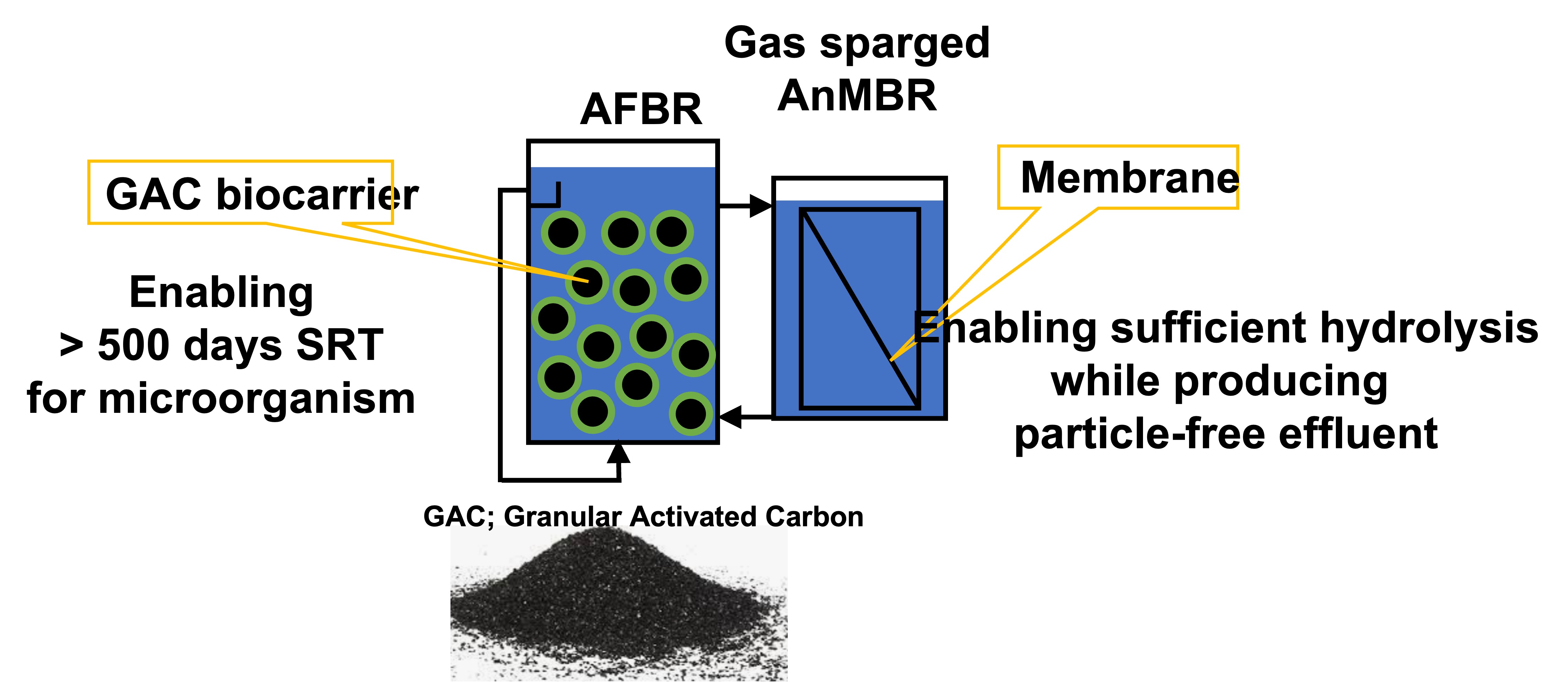

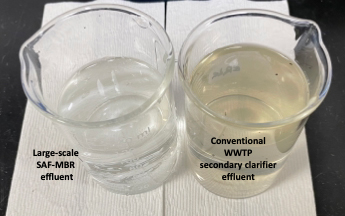

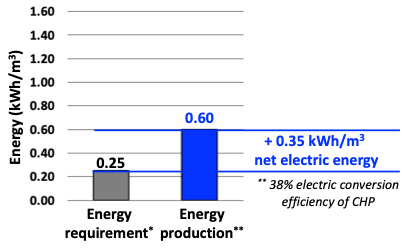

Grand Prize - University ResearchAnaerobic Fluidized Bed Membrane Bioreactor for Net Energy Production and Highly Efficient Treatment of Domestic Wastewater with Low Production of Waste BiosolidsEntrant: Craig S. Criddle, Stanford University Entrant Profile Craig Criddle is a Professor of Civil and Environmental Engineering at Stanford University and Senior Fellow in the Woods Institute for the Environment at Stanford. His specialty is microbial biotechnology for recovery of clean water, renewable energy, and renewable materials. He received his PhD from Stanford and began his academic career in 1989 at Michigan State University. After returning to Stanford in 1998, he has led research teams focused on groundwater bioremediation, biological wastewater treatment and reuse, and bioplastics from organic waste feedstocks. He has many refereed publications and patents and is co-author with award-winning San Francisco cartoonist Larry Gonick of the “Cartoon Guide to Chemistry”, a widely used supplement for high school and first year college chemistry classes. At present, he directs the Codiga Resource Recovery Center at Stanford. The Center’s goals are to accelerate development and adoption of promising resource recovery technologies and to train and inspire a new generation of students for continued innovation. Professor Criddle served as a Principal Investigator for the project entitled “Anaerobic fluidized bed membrane bioreactor for net energy production and highly efficient treatment of domestic wastewater with low production of waste biosolids.” Other members of the researcher team included Chungheon Shin, Sebastien Tilmans, and Professor Perry McCarty at Stanford University and staff members Arvind Akela and Alexandre Miot at at Silicon Valley Clean Water. Project DescriptionA team of investigators with the Stanford University Department of Civil and Environmental Engineering has developed an anaerobic staged anaerobic fluidized membrane bioreactor (SAF-MBR) for highly efficient treatment of domestic wastewater, which produces rather than consumes energy and with minimum production of waste biological solids when compared with conventional aerobic secondary wastewater treatment systems. Here, anaerobic microorganisms, including methanogens, convert biodegradable organic matter into methane. Thus, energy is recovered from domestic wastewater rather than requiring energy-intensive aeration. Because anaerobic microorganisms have low growth yields, the SAF-MBR produces minimal biosolids wastes, which are expensive to treat and dispose. The SAF-MBR system incorporates granular activated carbon (GAC) biocarriers and submerged membranes, enabling robust and energy-efficient treatment, even when operated at normal wastewater temperatures and short hydraulic retention time (HRT) as low as ~ 5 h. The GAC biocarriers coupled with low biosolids production permits a stable and long solids retention time (SRT) for anaerobic microorganisms (> 500 days), including Methanothrix, a key acetoclastic methanogen that produces extremely low acetate concentration in the effluent. Such a long SRT of anaerobic microorganisms guarantees high-quality effluent (i.e., volatile fatty acids concentration in effluent < 0.4 mg/L as COD). The GAC biocarriers also enable a low mixed liquor suspended solids (MLSS) concentration in the system, including in the membrane tank. The low MLSS concentration also facilitates energy-efficient membrane fouling control. The submerged membranes provide sufficient time for hydrolysis of complex organic matter, which can then be converted to methane, enabling more efficient COD removal and increased energy recovery. In a first version of the SAF-MBR, developed in 2013 by Prof. Perry McCarty and his former student, Prof. Jaeho Bae, membrane fouling control was achieved by allowing fluidized GAC particles to scour the membranes. Test results were promising, including high effluent quality, low biosolids production, and energy production, but resulted in rapid membrane damage due to abrasion by the fluidized GAC particles, which can cause substantial costs for membrane replacements. Professor Criddle led a team at Stanford that designed and tested a hybrid SAF-MBR system, incorporating a gas-sparged membrane fouling control system to avoid membrane damage. The resulting system uses an energy-efficient membrane gas sparging system (LEAPmbr diffusers) developed by SUEZ. The team is currently operating two hybrid SAF-MBR systems, one at a pilot scale at the Stanford Campus (Stanford, CA) and another at a larger-scale pilot plant at Silicon Valley Clean Water (Redwood City, CA). Stanford Utilities Department and other sponsors supported construction, operation, and improvements in a similar pilot-scale system at the Codiga Resource Recovery Center on the Stanford Campus. The pilot-scale system has been operated since 2018. The system’s volume is 4.5 m3 and contains two membrane modules (ZeeWeed 500D, SUEZ) with two LEAPmbr diffusers (SUEZ). Under steady-state operating conditions, the system has been treating 20 m3/d of Stanford domestic wastewater at 5 h HRT, 22 d SRT, and 12 L/m2/h net membrane flux. With a net efficiency of methane conversion into electricity of 38%, the net electrical energy produced by the system is 0.39 kWh per cubic meter of treated wastewater, compared with the energy required for system operation of 0.28 kWh/m3. No energy is required for wastewater heating. To our knowledge, this is the first anaerobic secondary treatment system that has achieved net energy positive operation at pilot scale in a temperate climate. Because of the severe California water shortage and the high cost of energy for wastewater treatment, water utility leaders at Silicon Valley Clean Water (SVCW, Redwood City, CA) were impressed with the SAF-MBR’s processes efficiency and energy potential. SVCW led a successful effort to win financial support from the California Energy Commission, and built a larger-scale demonstration system at their facility. SVCW is now beginning further work with funding from the US Bureau of Reclamation and the California State Water Resources Control Board to use the SAF-MBR for reclamation of non-potable and potable water from domestic wastewater. The Stanford team is working with SVCW in the design and operation of that facility. The SAF-MBR at SVCW has been operating since April 2021. It has a 19.4 m3 volume and is equipped with nine membrane modules (ZeeWeed 500D, SUEZ) and eight LEAPmbr diffusers (SUEZ). Under steady-state operation with 5 h HRT, 22 d SRT, and 12 L/m2/h net membrane flux, the system treats 90 m3 of primary treated influent each day. The influent has a mean COD of 550 mg/L, and the mean effluent COD is 35 mg/L, yielding a high COD removal efficiency of 94%. The COD removal efficiency was stable even while operating with wastewater temperature as low as ~ 60°F during the Winter (December 2021). Biosolids production of the SAF-MBR was only 0.02 gVSS/gCODremoved, much lower than the typical biosolids production from conventional aerobic secondary treatment of about 0.2 gVSS/gCODremoved. Cost savings and energy production by the SAF-MBR system can be substantial! At the SVCW facility, the produced methane could be used to generate 0.60 kWh/m3 electric energy (assuming 38% conversion efficiency), significantly more than the energy required for operation of 0.25 kWh/m3. Thus, net energy production is estimated to be 0.35 kWh/m3. In addition to that, waste biosolids production is expected to be 90% less than that normally produced in an aerobic system. The surplus energy alone could largely compensate for the energy required in a post-treatment process for potable water recovery (i.e., reverse osmosis energy requirement of ~ 0.5 kWh/m3, including pretreatment). Click images to enlarge in separate window. Click here to return to the list of 2022 winners. |