- Home

- Contact Us

- News & Events

- Awards

- AAEES Awards Criteria

- 40 Under 40 Recognition Program

- Edward J.Cleary Award

- Excellence in Environmental Engineering and Science Education

- Gordon Maskew Fair Award

- Honorary Member

- International Honorary Member

- Ralph and Joe Bales Graber Science Award

- Stanley E. Kappe Award

- Environmental Communications Awards Competition

- Excellence in Environmental Engineering and Science Competition

- The AAEES Chapter Blue Marble Award

- Resources

- AAEES Microcredentials

- Annual Reports

- AAEES Press Releases

- AAEES Website How To VIdeos

- Environmental Engineer and Scientist

- Environmental Engineering Body of Knowledge

- PFAS Resources

- Specialty Examination Guide

- Students and Young Professionals Resources

- Who's Who in Environmental Engineering & Science®

- Leadership Opportunities

- Membership

- Donate

- Jobs

2022 Excellence in Environmental Engineering and Science® Awards Competition Winner

Grand Prize - Design and Grand Prize - 50th Anniversary of the Clean Water ActRegional San EchoWater BNR ProjectEntrant: Black & Veatch Entrant Profile

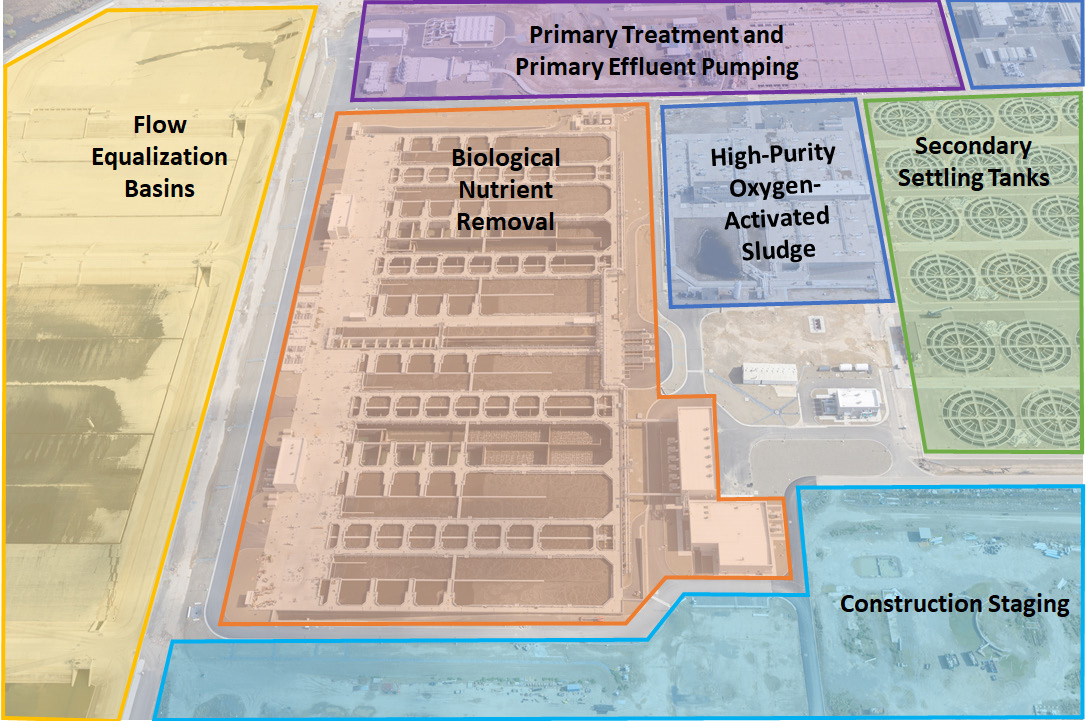

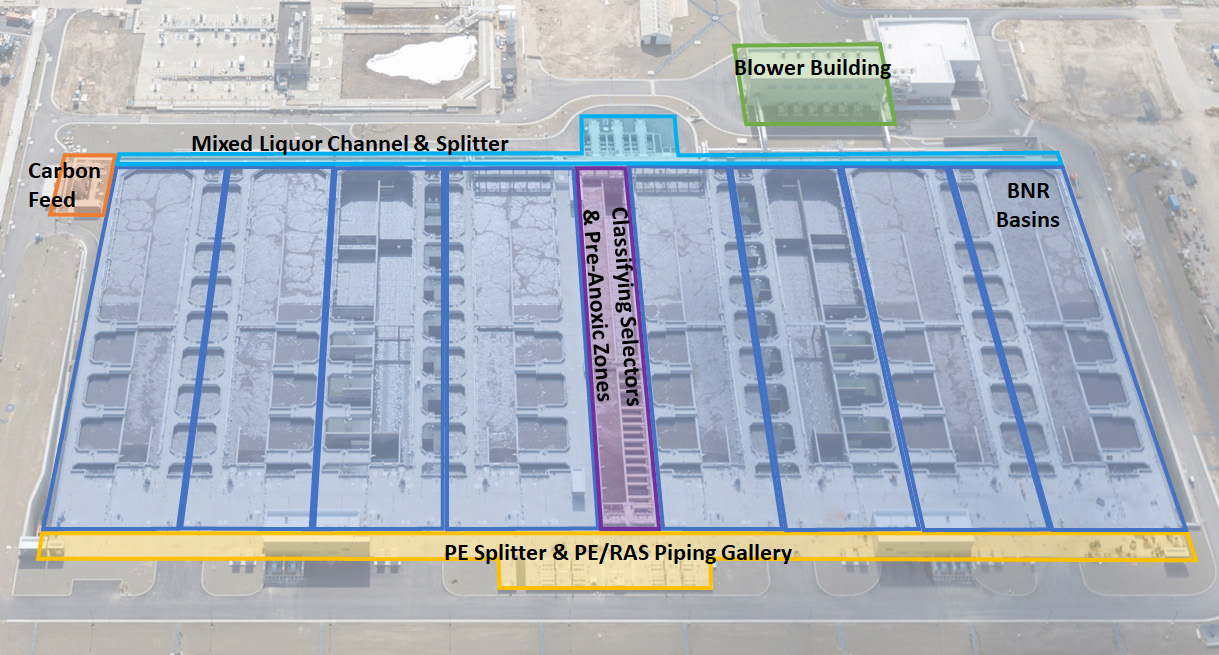

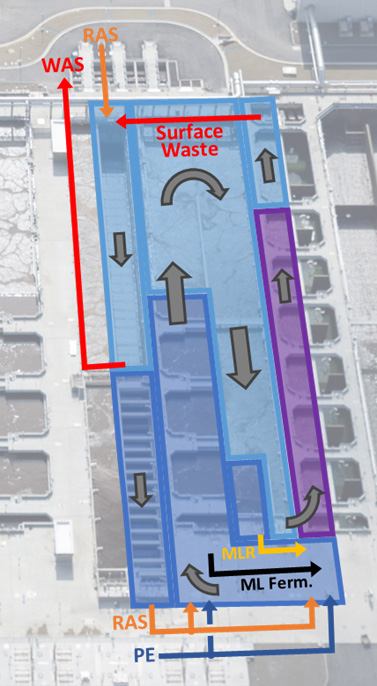

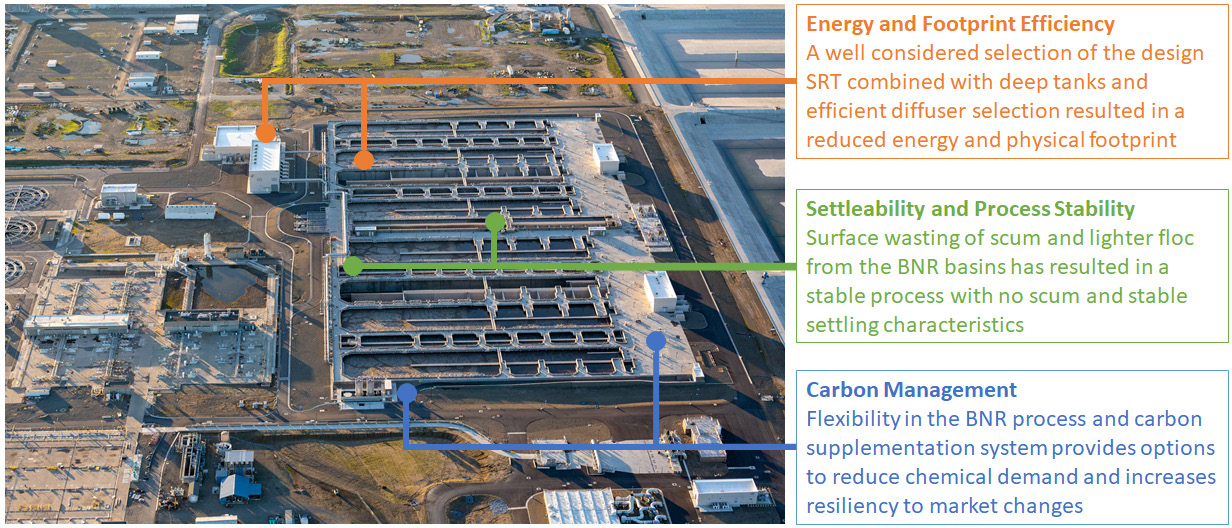

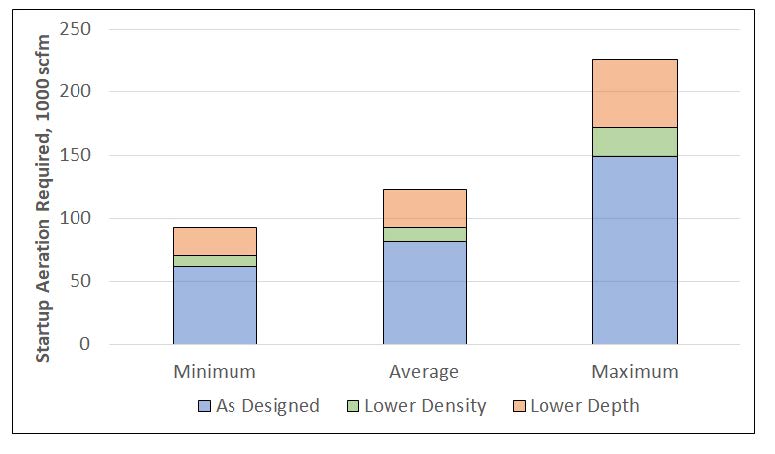

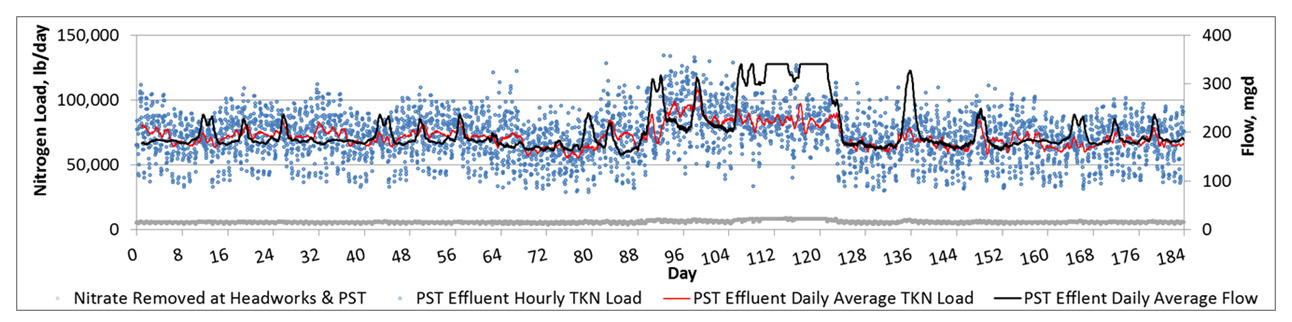

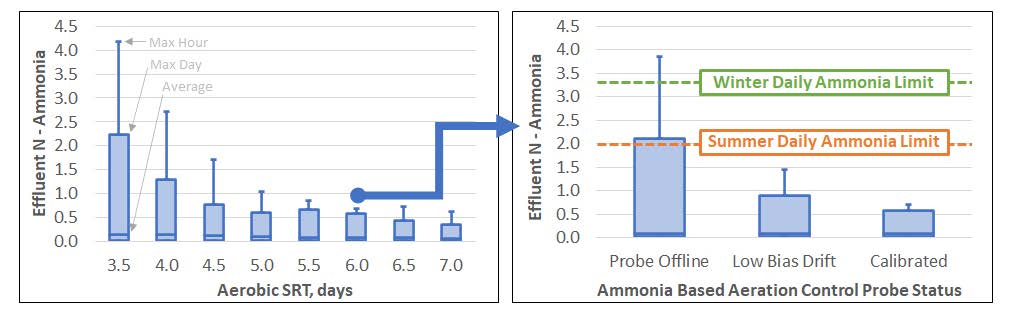

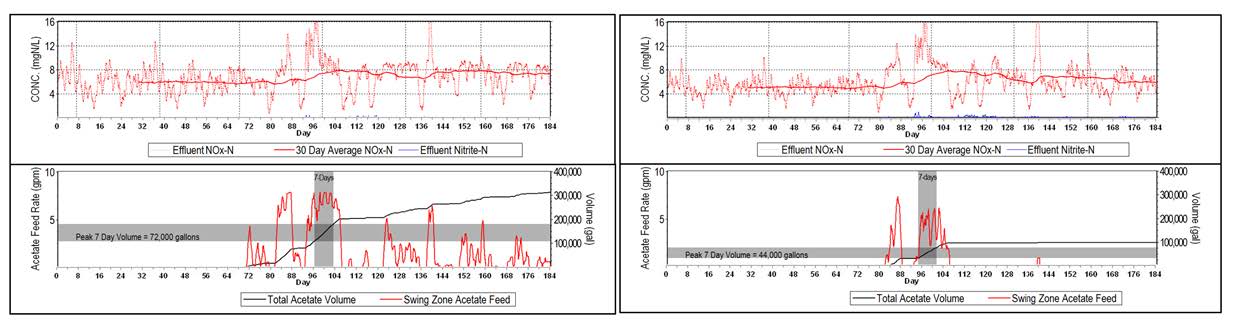

Black & Veatch (BV) provides integrated engineering, procurement, consulting, and construction services to public and private clients, promoting the resilience and reliability of infrastructure assets that improve the quality of life. The company is a global leader in advanced wastewater treatment, particularly the management of nutrients. It designed the biological nutrient removal facilities added under the EchoWater project by Regional San to improve the effluent discharged by Sacramento’s wastewater treatment plant and promote its reuse for landscaping and agricultural applications. Project DescriptionDrivers and ChallengesIn 2010, the Sacramento Regional County Sanitation District (Regional San) was issued stringent new treatment requirements to be met by 2023. At the time, the district’s secondary treatment facility used High Purity Oxygen Activated Sludge (HPOAS) to remove of organics and solids only. As a central component of the EchoWater project, which was implemented by the district to comply with the new treatment requirements, new biological nutrient removal (BNR) basins were added to the facility. Their purpose: to achieve ammonia and nitrogen (N) removal in the secondary process, thereby replacing the HPOAS system and reducing N discharge to the Sacramento River. Production of high-quality secondary effluent was also needed to serve as source water for Title 22 reuse and because water from the Sacramento River is intercepted downstream from the plant and pumped to southern California to augment water supplies there. Specific design challenges were posed by the intersection of extreme influent dynamics and stringent effluent ammonia limits. Storms result in sustained influent flow of 330 million gallons per day (MGD) coinciding with peak influent N loads while the average daily ammonia cannot exceed 2.0 mg/L-N in summer and 3.3 mg/L-N in winter. Other challenges impacted the ability to meet nitrate limits. Influent wastewater was septic, and at the time of design high doses of chlorine were used to combat odors, oxidizing influent organics (COD) required for denitrification. This resulted in 6-7 mgCOD/mgN in the influent, necessitating carbon augmentation to meet the monthly nitrate limit of 10 mgN/L. Chlorination has been replaced by nitrate addition (from centrate nitrification), which somewhat reduced N loading to secondary treatment. Other challenges were presented by schedule, site, and environmental impact drivers. The schedule required rapid execution, but due to the immense scale many years passed between conceptual design and startup, adding to design uncertainty. A constrained site using the existing primary and secondary clarifiers and the desire to limit energy use and overall environmental impact meant that efficiency in design and operational energy use were critically important. To address these challenges efficiently without undue risk, a combination of dynamic seasonal modeling and full-scale pilot testing, and the application of cutting-edge applied research were used during design. Efficiency of Footprint and Energy UseA primary design objective was the selection of an appropriate solids retention time (SRT) to meet the stringent ammonia requirement while minimizing footprint. The greatest challenge comes when winter storms result in high flow and N loads at low temperature resulting from the collection system and equalization processes. By explicitly modeling these influent dynamics, safety factors typically applied to SRT to address influent variability could be reduced. A sensitivity analysis of SRT impact on peak effluent ammonia was used to select a 6-day aerobic SRT, reducing the required aerobic volume by approximately 20% versus a more traditional approach. Volume requirements were further reduced by incorporating diffused aeration into post-anoxic swing zones and counting this as aerobic volume. Incorporation of ammonia or nitrate-based control of swing zone aeration or carbon dosage ensured that daily ammonia and monthly nitrate limits could be met. Careful analysis of influent data, piloting to estimate nitrification rates, extensive dynamic modeling with incorporation of controls, and the incorporation of online SRT control into the design lent further confidence to this approach. A high-efficiency diffuser design was also implemented by leveraging applied research into diffuser fouling and aging, and applying that to an evaluated bid process to select an efficient aeration system using tubular silicone diffusers. Selection was based on life-cycle cost and used extensive testing to validate efficiency guarantees that, combined with a basin depth of 26 feet, resulted in a design that reliably exceeds performance demands while also being efficient in terms of construction and operation, and low in environmental impact. Effluent Quality and ResiliencyFast-settling and well-flocculating biomass is necessary to achieve high-quality effluent for discharge and reuse while being resilient to increasingly frequent high-flow events. Various bulking and foam forming organisms are detrimental to this aim, and the construction of an entirely greenfield BNR basin presented the opportunity to incorporate comprehensive industry knowledge of growth pressures into the design to out-select these organisms. This is achieved by surface wasting of lighter foam or scum from various hang-up points in the process, resulting in free flow across the surface of BNR basins. Surface waste from the process is then discharged to a surface wasting classifying selector that receives return sludge and where lighter foam-forming sludge is ultimately wasted from the process. Because of the low COD/N ratio, carbon management within the secondary process is also critically important to effluent quality and resiliency. The carbon feed system is flexible and allows for feed of different carbon sources to several locations and, further, the carbon supplementation requirements are minimized by providing sufficient unaerated volume at the front of the BNR process. This volume, which the process flexibility provided, and high mixed liquor recycle capacity allow for different operational strategies, depending on influent characteristics and N removal or carbon management goals. By accumulating mixed liquor and fermenting it within unaerated zones, endogenous carbon can be used to reduce the need for external supplementation. Together, these design features reduce the impact of supply chain disruptions and allow excess nitrate to be removed without external carbon addition under ideal circumstances. ResultsBased on the first year of full-scale operation, the design approach relying on extensive dynamic modeling, testing and the application of cutting-edge process understanding has addressed many project-specific challenges. Effluent quality is stable with lower aeration and carbon requirements than would be expected for the level of treatment achieved. Further, scum and foam have been almost non-existent on the basin and settling rates in the final clarifiers have been stable while staying well below design values. A record storm in October 2021 during the first year of full-scale operation tested the design beyond what was planned for at the outset of the program. Despite the challenge, the process was stable. No upsets in operation or effluent quality resulted. Click images to enlarge in separate window. Click here to return to the list of 2022 winners. |