- Home

- Contact Us

- News & Events

- Awards

- AAEES Awards Criteria

- 40 Under 40 Recognition Program

- Edward J.Cleary Award

- Excellence in Environmental Engineering and Science Education

- Gordon Maskew Fair Award

- Honorary Member

- International Honorary Member

- Ralph and Joe Bales Graber Science Award

- Stanley E. Kappe Award

- Environmental Communications Awards Competition

- Excellence in Environmental Engineering and Science Competition

- The AAEES Chapter Blue Marble Award

- Resources

- AAEES Microcredentials

- Annual Reports

- AAEES Press Releases

- AAEES Website How To VIdeos

- Environmental Engineer and Scientist

- Environmental Engineering Body of Knowledge

- PFAS Resources

- Specialty Examination Guide

- Students and Young Professionals Resources

- Who's Who in Environmental Engineering & Science®

- Leadership Opportunities

- Membership

- Donate

- Jobs

2021 Excellence in Environmental Engineering and Science® Awards Competition Winner

Superior AchievementCategory Entered: Environmental SustainabilitySustainable Green Fleet: Clean Fuel for LA TodayEntrant: Los Angeles County Sanitation Districts Entrant Profile

Figure 1: Material handler with smart hydraulics which reduces fuel consumption.

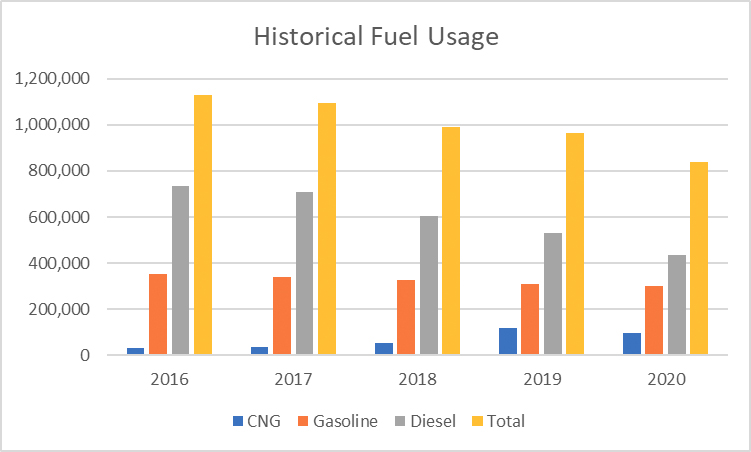

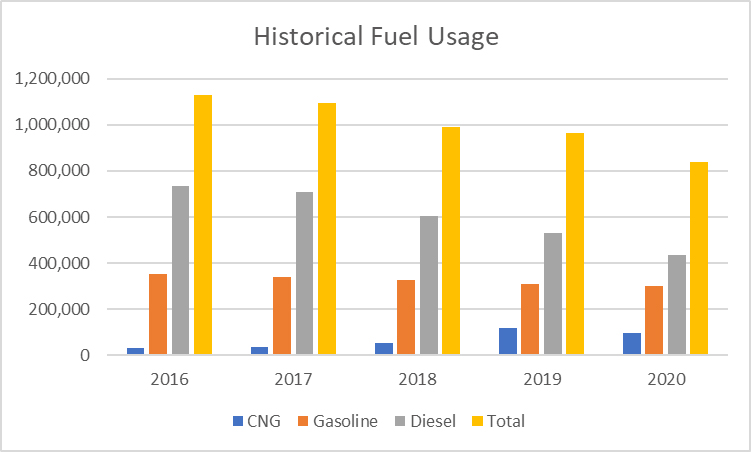

Figure 2: Sanitation Districts fuel usage (2016 to 2020).

Figure 3: CNG powered vacuum/jetter sewer cleaning truck.

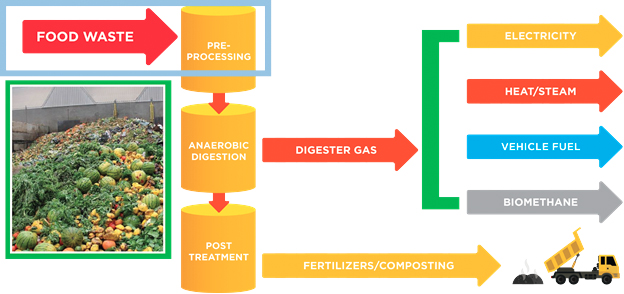

Figure 4: Sanitation Districts Food Waste to renewable energy program.

Figure 5: Mean Green Rival electric mower.

Figure 6: Maintenance on RNG powered transfer truck.

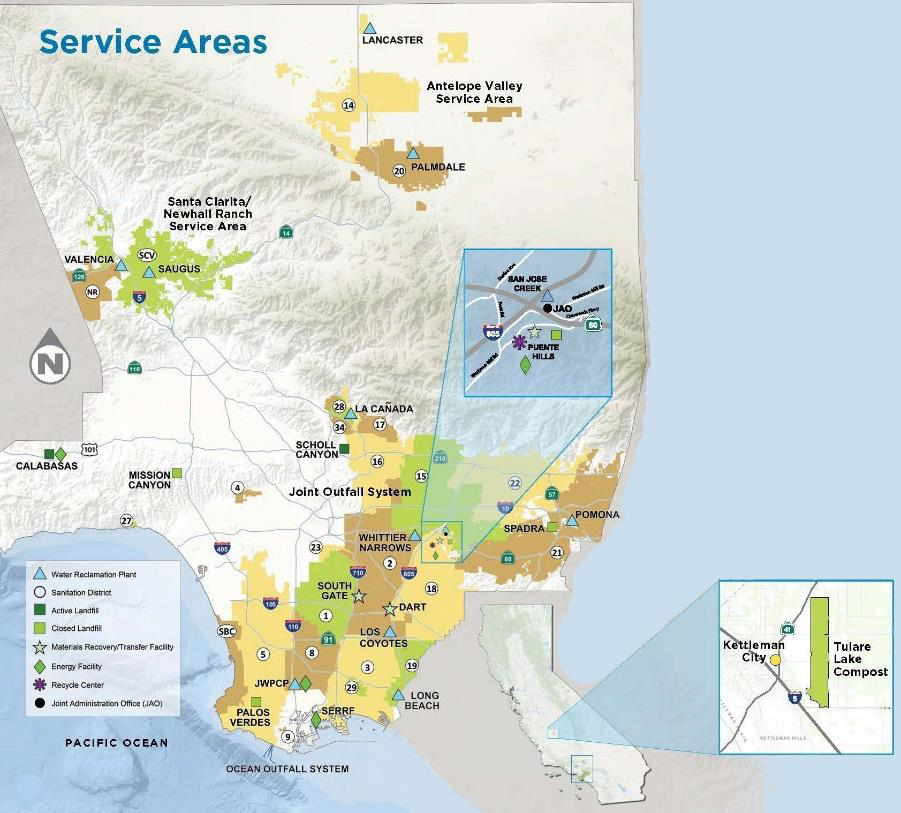

Figure 7: DC fast charging stations at the Sanitation Disticts main office. The Los Angeles County Sanitation Districts (Sanitation Districts) are a regional public agency that serves the wastewater and solid waste management needs of 78 cities and unincorporated areas in Los Angeles County. The agency protects public health and the environment and, in doing so, converts waste into resources like recycled water, green energy and recycled materials. The agency operates and maintains a regional wastewater collection system (which includes approximately 1,400 miles of sewers, 48 pumping plants, and 11 wastewater treatment plants) that treats about half the County’s wastewater or about 400 million gallons of sewage per day. The recycled water produced by our treatment plants is beneficially reused at more than 950 sites, which contributes to a more sustainable Southern California. The agency also operates and maintains a regional solid waste management system (which includes two active landfills, two energy recovery facilities, three materials recovery facilities, and one recycle center) that accommodates about one-fourth of the County’s solid waste management needs. The Sanitation Districts utilize an extensive fleet of vehicles and off-road equipment to provide its essential services. Historically, the agency’s fleet was powered by fossil fuel that, when combusted, produces greenhouse gases that contribute to global climate change. In 2015, the agency began its “Sustainable Green Fleet: Reducing Our Carbon Footprint” program to reduce greenhouse gas impacts from its fleet. The program has resulted in the agency electrifying some of its fleet, utilizing renewable fuels, and producing renewable vehicle fuel. Project DescriptionSustainable Green Fleet: Reducing Our Carbon FootprintThe Los Angeles County Sanitation Districts (Sanitation Districts) rely on a fleet of 687 on-road vehicles, 85 utility carts, and 354 pieces of off-road equipment to help provide regional wastewater and solid waste management. In 2020, the agency’s vehicles travelled 4,151,990 miles and their off-road equipment was operated over 140,000 hours. The vehicles and equipment used to perform the agency’s essential duties have historically relied on fossil fuels (gasoline and diesel). Fossil fuel combustion is the biggest source of human-caused greenhouse gas (GHG) emissions in the United States, which can negatively impact human health and the environment. Thus, the Sanitation Districts have been moving to a green fleet. Already, this transition has reduced the agency’s GHG emissions, including a 43% reduction in fossil fuel use in 2020 alone. Improvements have been achieved by transitioning to alternative and renewable fuels; using technology and data to optimize service and reduce fuel consumption; and purchasing more fuel-efficient vehicles and equipment with hybrid technologies (see Figure 1). Over the past five years, the Sanitation Districts have reduced their fleet fuel consumption from 1.13 million gallons per year to 840,000 gallons in 2020. That’s a 25% reduction (see Figure 2). Not only has fuel consumption been reduced, but renewable fuel usage has increased from 3% in 2016 to 53% in 2020. Increasing the use of Renewable Natural Gas (RNG) and Renewable Diesel (RD) has reduced GHG emissions. Transitioning to alternative and renewable fuels has required a lot of research and work, including verifying fuel capacity; adding fuel storage tanks without restricting operation or visibility; designing and installing new fueling infrastructure; and training staff on the new maintenance and repair procedures. Compressed Natural Gas (CNG)The Sanitation Districts have been using CNG vehicles over the past 20 years. The agency has 91 vehicles powered by CNG, which represents 13% of their on-road fleet. Nineteen are heavy-duty trucks, which have certified near-zero emission engines. This is the cleanest commercially available diesel technology today. Over the past five years, the Sanitation Districts entire fleet of vacuum/jetter sewer cleaning trucks have transitioned from diesel to CNG (see Figure 3). The trucks are critical for routine sewer maintenance and emergency response to sewer overflows. Therefore, a dependable source of fuel is a must. One challenge was finding space for the additional CNG storage tanks on trucks that are already loaded with other equipment. The CNG station at the Puente Hills Materials Recovery Facility was upgraded, making the station faster and more reliable. In summer 2021, the agency will install new CNG fueling infrastructure and upgrade an existing CNG fueling infrastructure. These improvements will provide fast and reliable fueling for the growing fleet of CNG vehicles. The CNG station at the agency’s largest wastewater treatment plant, the Joint Water Pollution Control Plant (JWPCP), will be upgraded and expanded next. Food Waste to Renewable Natural Gas (RNG)Since 2016, the Sanitation Districts have been recycling food waste into green energy to help their member cities meet state organic waste recycling requirements. In 2020, this system was expanded to produce renewable natural gas, which is used to fuel vehicles. Waste haulers bring food waste slurry to JWPCP, where the food waste is anaerobically digested and converted to biogas. Some of the biogas is used at a power plant, which makes the JWPCP essentially energy self-sufficient. The remainder is sent to a biogas purification system that produces renewable natural gas that is dispensed at a nearby Sanitation Districts fueling station, which is also open to the public. This biogas reduces the need for natural gas and reduces greenhouse gas emissions. By the end of 2021, the vast majority of the CNG dispensed at this station will be RNG (see Figure 4). Electric Vehicles (EVs)The Sanitation Districts are in the process of electrifying their fleet. Over the past three years, the agency has purchased 48 electric cars and four hybrids, which has reduced fossil fuel consumption by more than 26,000 gallons per year. To support the EV fleet, the Sanitation Districts have installed 84 EV charging stations. At most facilities, the EV chargers are used by agency vehicles, employee vehicles and the public. In 2020, the Sanitation Districts also purchased their first fully electric zero-emission ride-on mower, the Mean Green Rival (see Figure 5). Renewable Diesel (RD)Although most Sanitation Districts on-road vehicles are being transitioned to alternative fuels like CNG and electricity, the agency still needs off-road equipment that is only powered by diesel. The Sanitation Districts started using RD in September 2018. This fuel is produced from waste fats, oils and greases. RD reduces GHG emissions by about 75% and produces significantly less particulate matter and NOx (a common air pollutant) than diesel. Last year, over 80% of the agency’s diesel usage was RD. This year, the agency is targeting close to 100%. The agency is currently saving $0.24 per gallon compared to fossil-based diesel. Because RD burns cleaner, RD usage has extended maintenance intervals on engines. By summer 2021, the agency will have used over one million gallons of RD resulting in a cost savings of $193,000 and a reduction of over 7,600 metric tons of GHG emissions. That is equivalent to removing 4,260 cars from the road or planting more than 517,000 trees. MaintenanceThe transition to alternative fuels has required the agency to review and adjust maintenance practices. With EVs, there is no internal combustion engine, which means no oil changes. Mechanics and service crew workers have adapted to the increased electronics, smart hydraulic systems and transmissions, different types of fuel systems, and the need for pressure vessel inspections. What is Next?The Sanitation Districts’ transition is not complete. The agency is focused on expanding the EV charging network at its facilities to meet growing needs. This expansion will require a greater number of DC Fast charging stations to support future medium- and heavy-duty EVs. The Sanitation Districts is committed to further protecting the environment by reducing its carbon footprint and increasing its production of renewable energy for the region. Click images to enlarge in separate window. Click here to return to the list of 2021 winners. |