- Home

- Contact Us

- News & Events

- Awards

- AAEES Awards Criteria

- 40 Under 40 Recognition Program

- Edward J.Cleary Award

- Excellence in Environmental Engineering and Science Education

- Gordon Maskew Fair Award

- Honorary Member

- International Honorary Member

- Ralph and Joe Bales Graber Science Award

- Stanley E. Kappe Award

- Environmental Communications Awards Competition

- Excellence in Environmental Engineering and Science Competition

- The AAEES Chapter Blue Marble Award

- Resources

- AAEES Microcredentials

- Annual Reports

- AAEES Press Releases

- AAEES Website How To VIdeos

- Environmental Engineer and Scientist

- Environmental Engineering Body of Knowledge

- PFAS Resources

- Specialty Examination Guide

- Students and Young Professionals Resources

- Who's Who in Environmental Engineering & Science®

- Leadership Opportunities

- Membership

- Donate

- Jobs

2021 Excellence in Environmental Engineering and Science® Awards Competition Winner

Grand Prize - ResearchBV Innovation Platform - MABR Research CollaborativeEntrant: Black & Veatch Entrant Profile

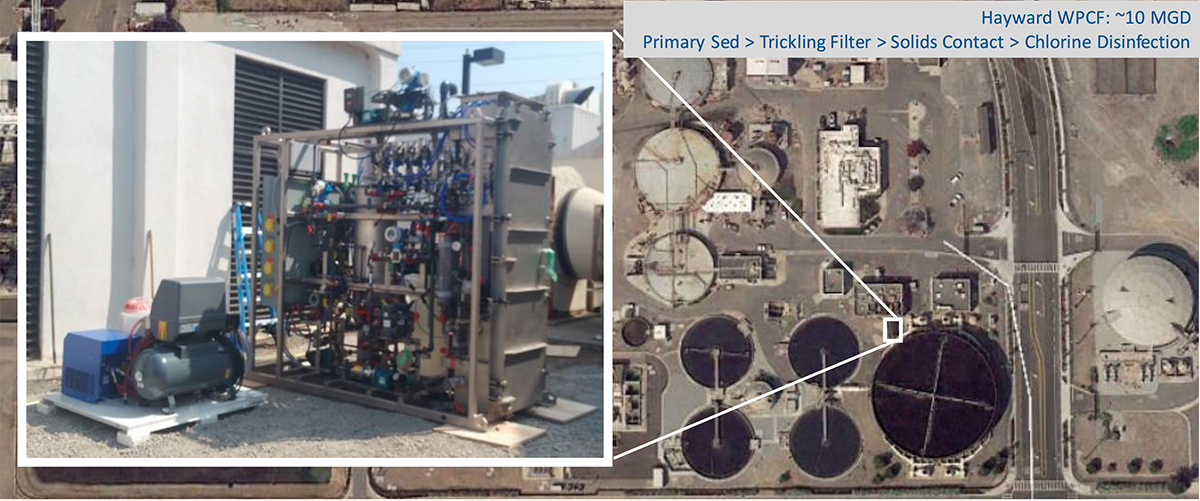

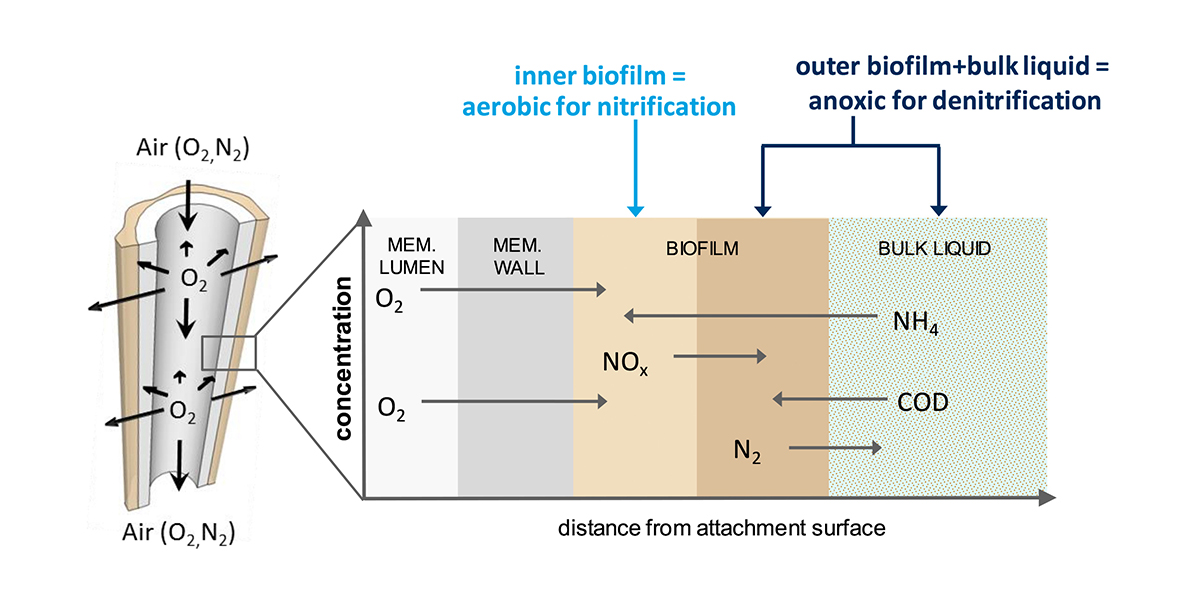

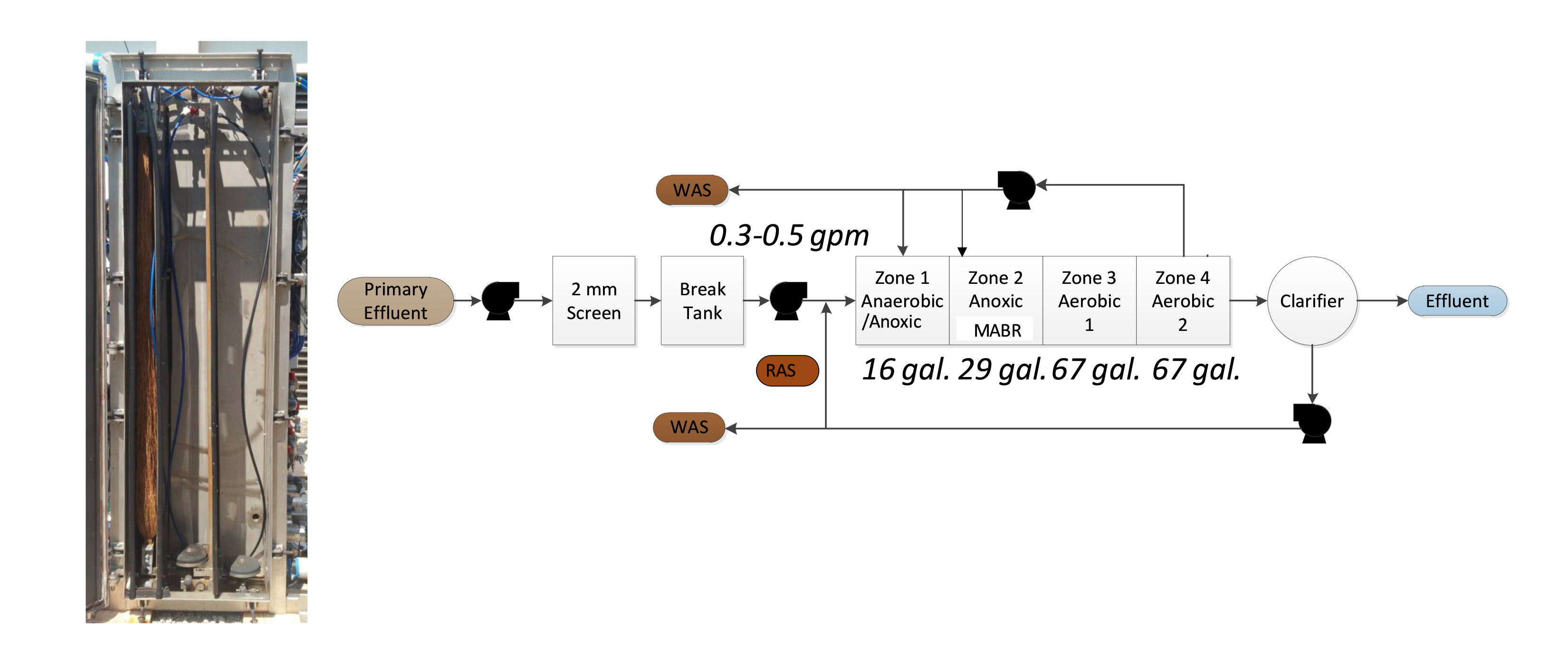

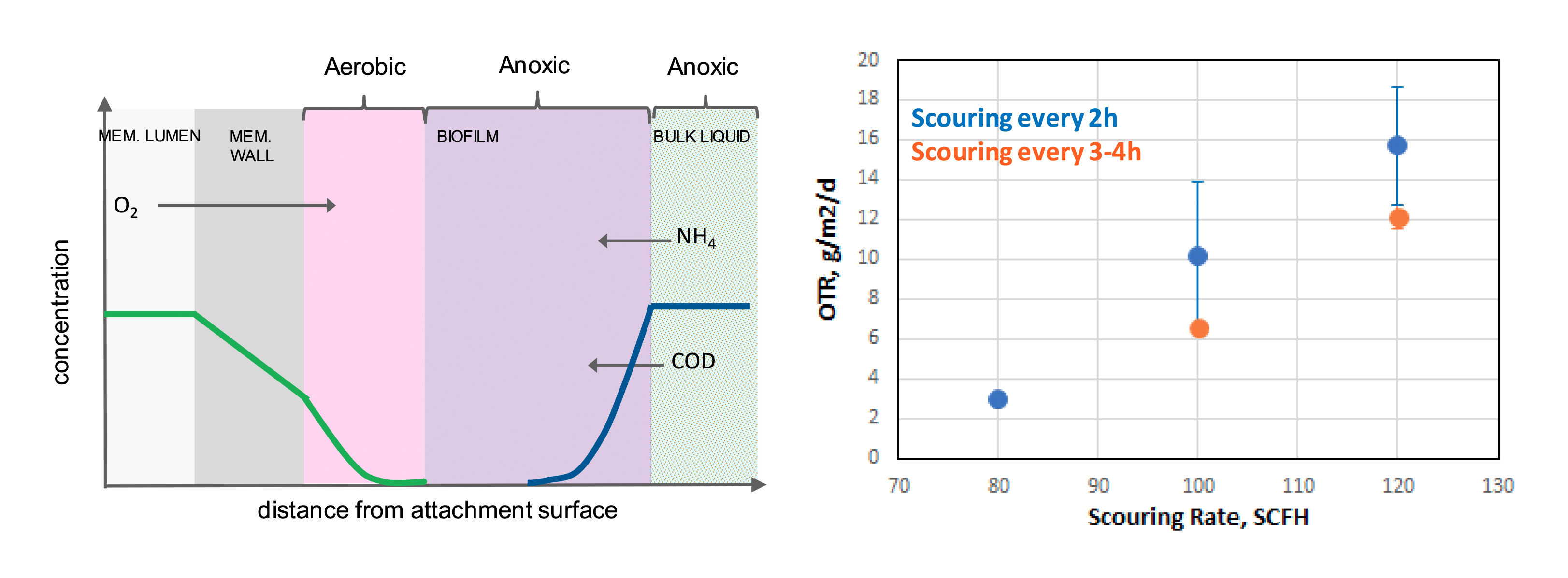

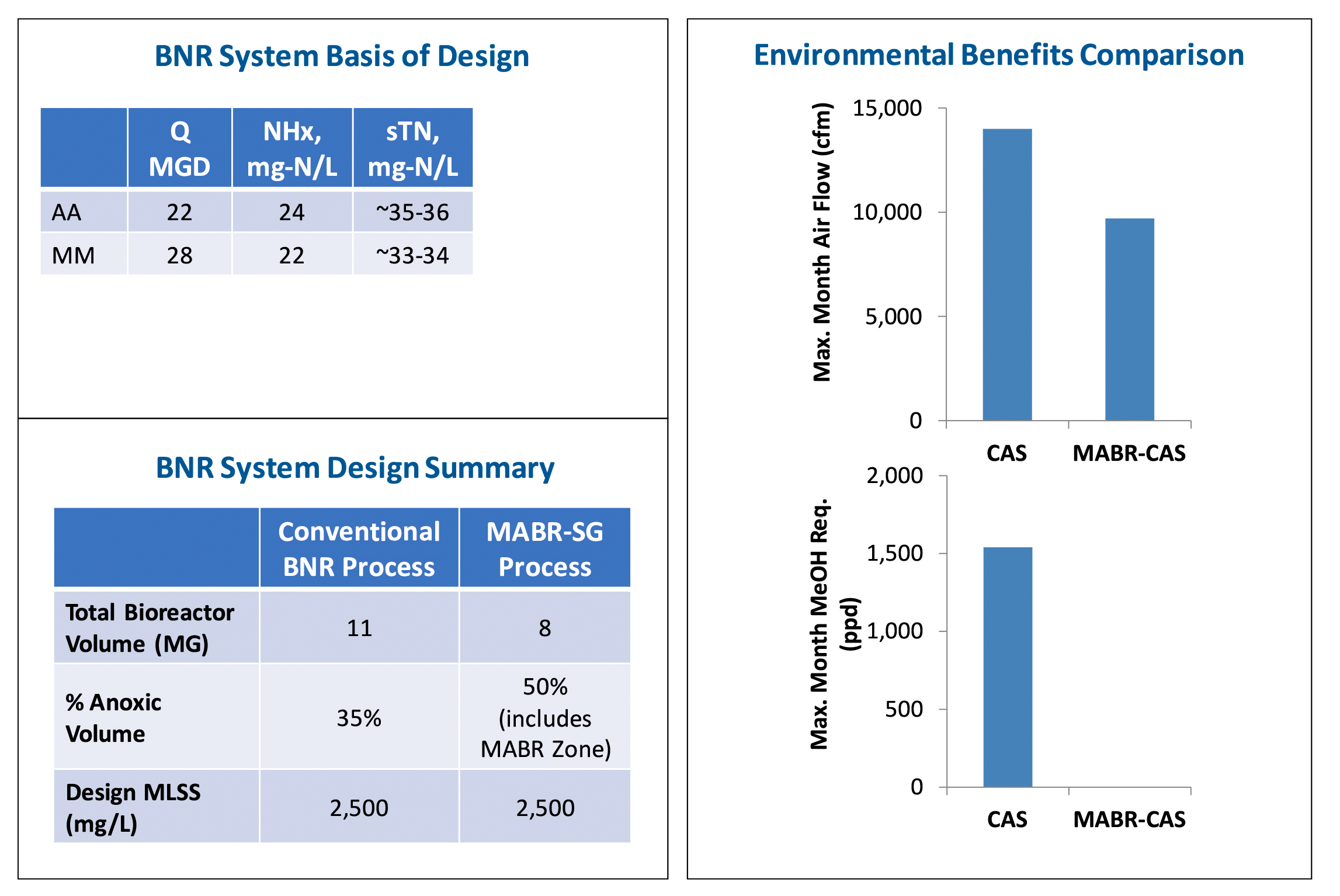

Black & Veatch (BV) is the owner of the BV Innovation Platform – MABR Research Collaborative. The BV Innovation Platform focuses on realizing resource recovery and sustainable treatment concepts, performing project-oriented research services including full-scale testing, demonstration facility design, treatability testing and technology evaluations. It assembled the team and served as Principal Investigator. It developed the plan, protocols and tests for the 170-gallon (645 L) hybrid MABR suspended-growth pilot. It further operated the pilot skid, conducted the lab-scale experiments, collected samples, and analyzed the data. The City of Hayward served as a committee member on the project. It provided space for the lab tests, helped with overnight sampling, shared electrical instrumentation equipment and assisted with the commissioning of the project. Suez was co-author of the research and provided the pilot skid with design modifications by Black & Veatch. It provided membrane-related support, including relevant data and experience on past projects. It also provided mechanical support for different components of the MABR technology. Project DescriptionResearch MotivationMembrane aerated biofilm reactors (MABRs) are an emerging biofilm-based biological nutrient removal (BNR) process intensification technology. Although the MABR process has been studied at lab-scale, a limited number of pilot or full-scale studies have been conducted. There are significant knowledge gaps, particularly related to the value proposition of the technology for process intensification. A Comprehensive, Integrated Approach to Applied ResearchOur MABR research collaborative of Black & Veatch (BV), Suez and the City of Hayward, CA evaluated a pilot-scale hybrid MABR-suspended growth (MABR-SG) process at the Hayward Water Pollution Control Facility (Figure 1). The MABR-SG process enables simultaneous, concurrent nitrification-denitrification within the MABR biofilm and denitrification in the anoxic mixed liquor, resulting in efficient total nitrogen removal in a single tank (Figure 2). An MABR-SG process offers process intensification and reduction in the greenhouse gas emissions. The MABR-SG process impacts water, air, land and system operations by enhancing BNR performance, maximizing the value of existing assets, requiring less energy, reducing GHG emissions and an opportunity produce more energy and return more carbon to the soil. Our integrated approach consisted of:

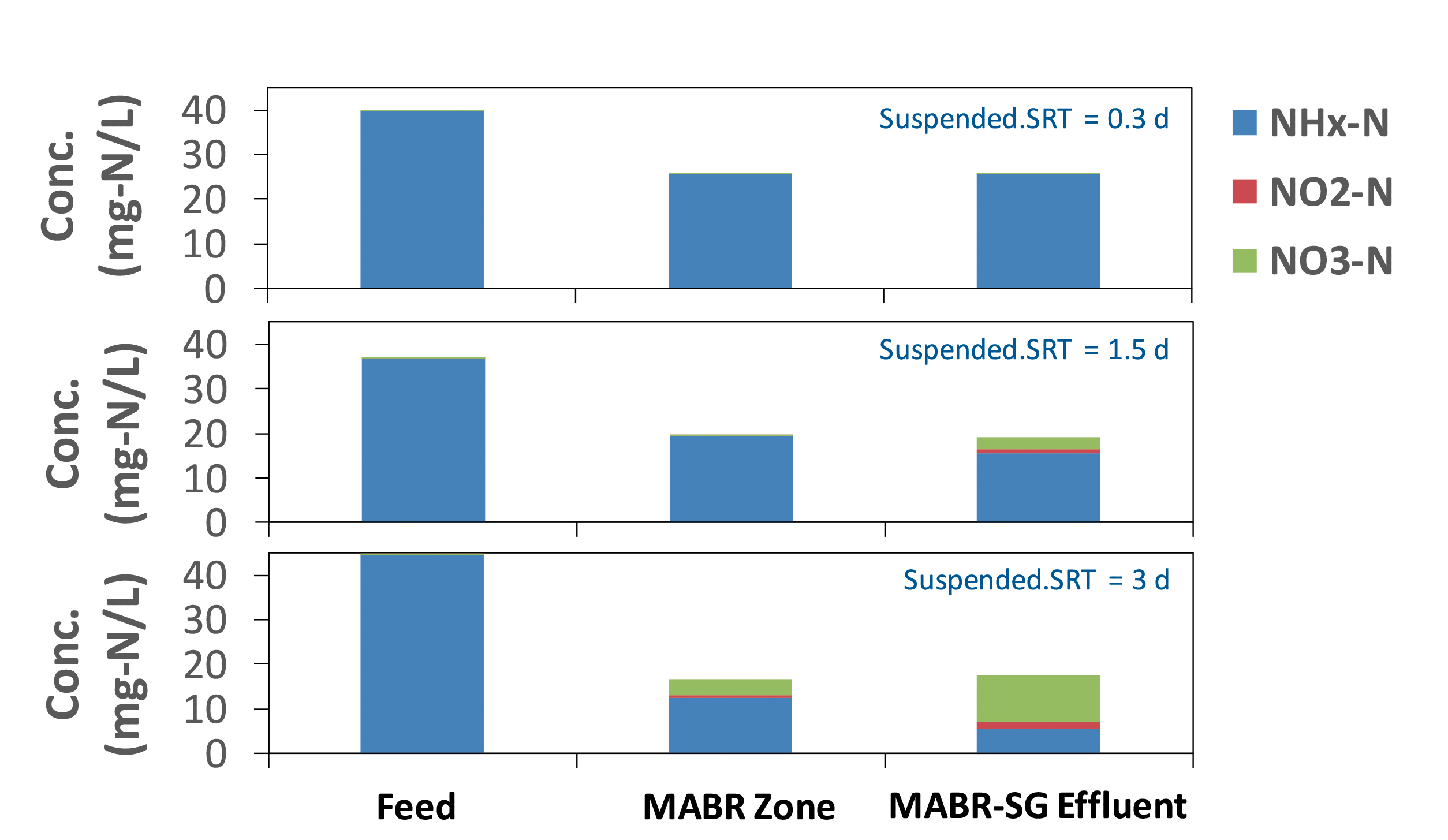

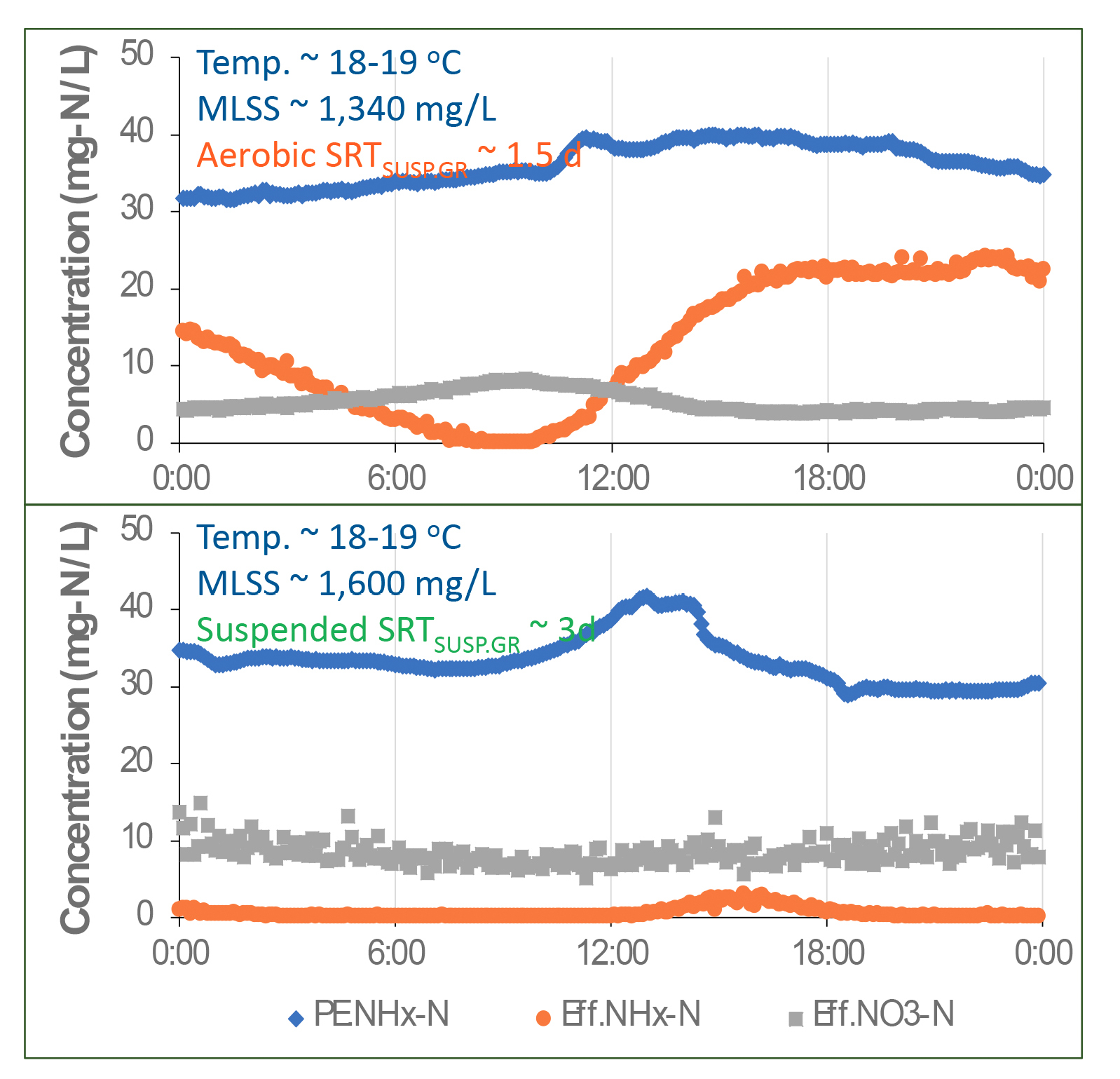

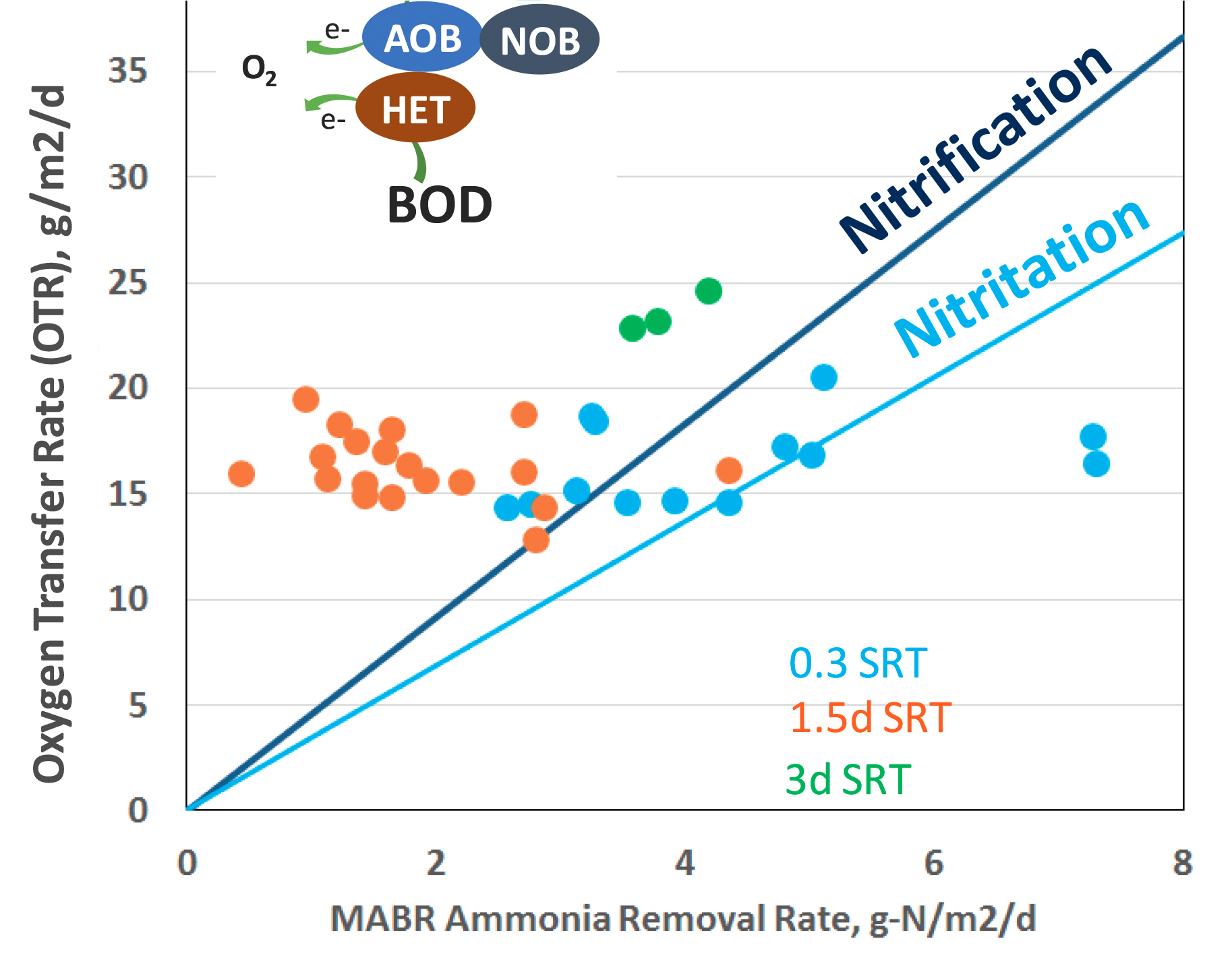

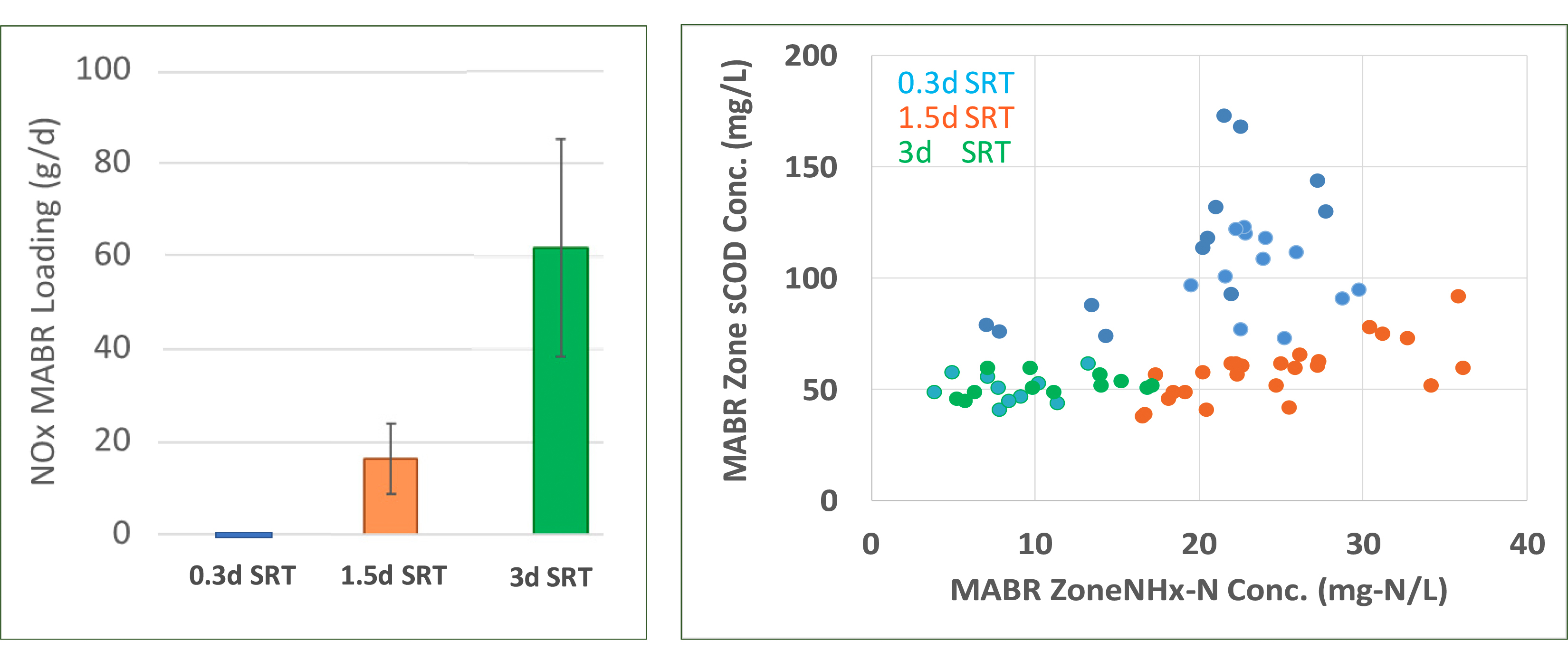

QualityA Technical Advisory Panel of industry experts from BV, Suez, Hayward and academia provided input and guidance on the research. A rigorous sampling and monitoring program was employed to characterize the performance of the MABR-SG process. Influent, bioreactor zones and effluent samples were routinely collected throughout the 2-year period and analyzed for chemical oxygen demand (COD), ammonia, total kjeldahl nitrogen (TKN), total phosphorus, alkalinity, nitrate, nitrite and total suspended solids (TSS) and volatile suspended solids (VSS). Analyses were conducted in accordance with standard methods. Additionally, during multiple short-term experiments, samples were collected every 2 hours across each zone of MABR-SG process to quantify diurnal performance. Biofilm and suspended mixed liquor were routinely sampled and the microbial communities were elucidated using high throughput 16S-rRNA sequencing and qPCR. Originality and InnovationKey findings include: An MABR-SG process can support significant process intensification.

The observed nitrification rate of the MABRSG process is variable and depends on multiple factors.

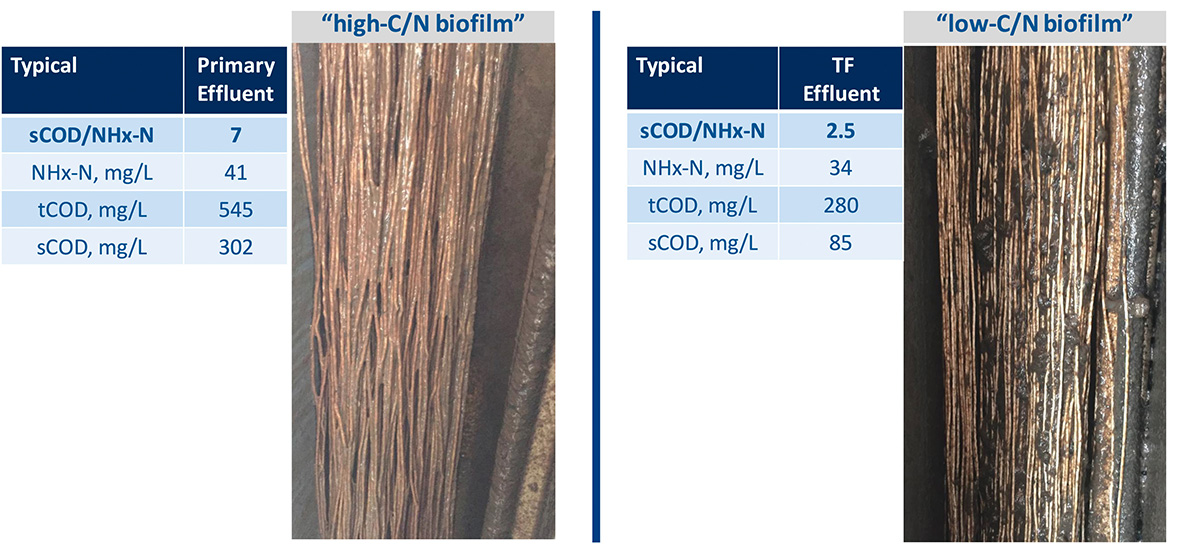

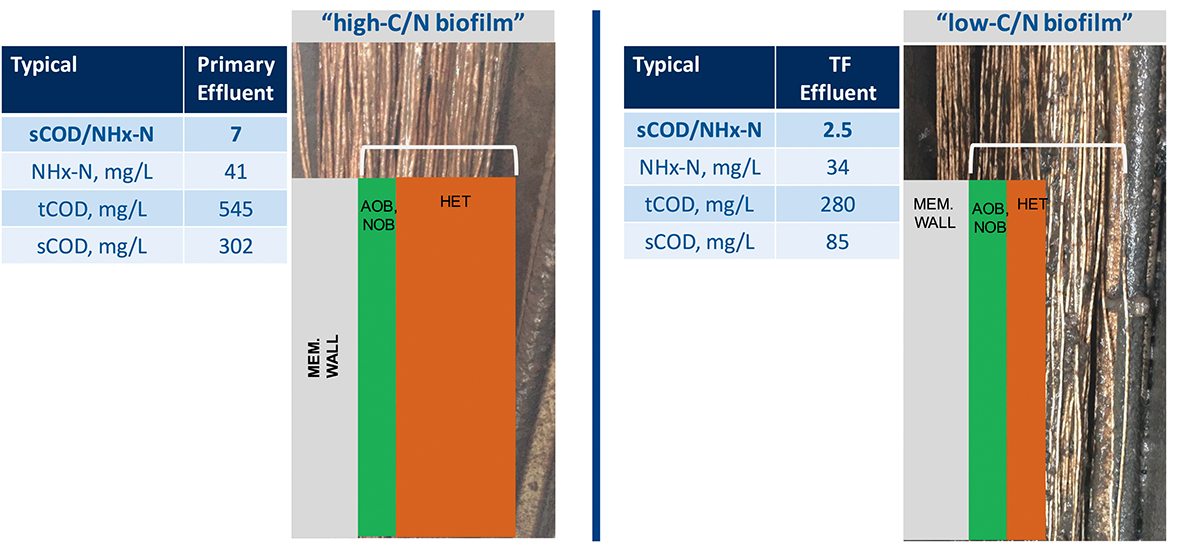

Biofilm structure and performance are strongly influenced by the BOD/N ratio of the influent.

Complexity of the ProblemThe challenges of testing MABRs at pilot scale include variability in the influent, which is an inevitable reality of “real-world” systems, lack of a controlled environment and equipment malfunction/failure. To overcome complexities associated with pilot-scale research, a multi-discipline team of professionals collaborated on the sampling, operation of the facility and analyses. This research dove deeper than typical “demonstration” work done at pilot scale. Experiments were carefully designed for specific and untested aspects. For example, the research systematically evaluated the seeding hypothesis – which has not been accomplished at this scale and is an essential basis for the value-proposition of MABR technology. Contribution to Social and Economic AdvancementThe research filled key knowledge gaps in the applicability of the MABR-SG process to achieve intensified nutrient removal. Existing biological reactors could be retrofitted to achieve a 50% to 100% increase in treatment process capacity without construction of new concrete tanks. In the San Francisco Bay Area alone, 39 utilities are working toward a collective goal to reduce their nutrient loading. This research suggests that the MABR-SG process could significantly reduce capital and operational costs of BNR upgrades, resulting in net environmental benefits (Figure 14). As utilities focus on the need for energy-efficient, low-GHG nutrient removal as part of a broader resource recovery and optimization portfolio, the MABR-SG hybrid process evaluated by this research provides an effective tool. It shows MABR technology is ready to be used in more applications. Click images to enlarge in separate window. Click here to return to the list of 2021 winners. |