- Home

- Contact Us

- News & Events

- Awards

- AAEES Awards Criteria

- 40 Under 40 Recognition Program

- Edward J.Cleary Award

- Excellence in Environmental Engineering and Science Education

- Gordon Maskew Fair Award

- Honorary Member

- International Honorary Member

- Ralph and Joe Bales Graber Science Award

- Stanley E. Kappe Award

- Environmental Communications Awards Competition

- Excellence in Environmental Engineering and Science Competition

- The AAEES Chapter Blue Marble Award

- Resources

- AAEES Microcredentials

- Annual Reports

- AAEES Press Releases

- AAEES Website How To VIdeos

- Environmental Engineer and Scientist

- Environmental Engineering Body of Knowledge

- PFAS Resources

- Specialty Examination Guide

- Students and Young Professionals Resources

- Who's Who in Environmental Engineering & Science®

- Leadership Opportunities

- Membership

- Donate

- Jobs

2019 Excellence in Environmental Engineering and Science® Awards Competition Winner

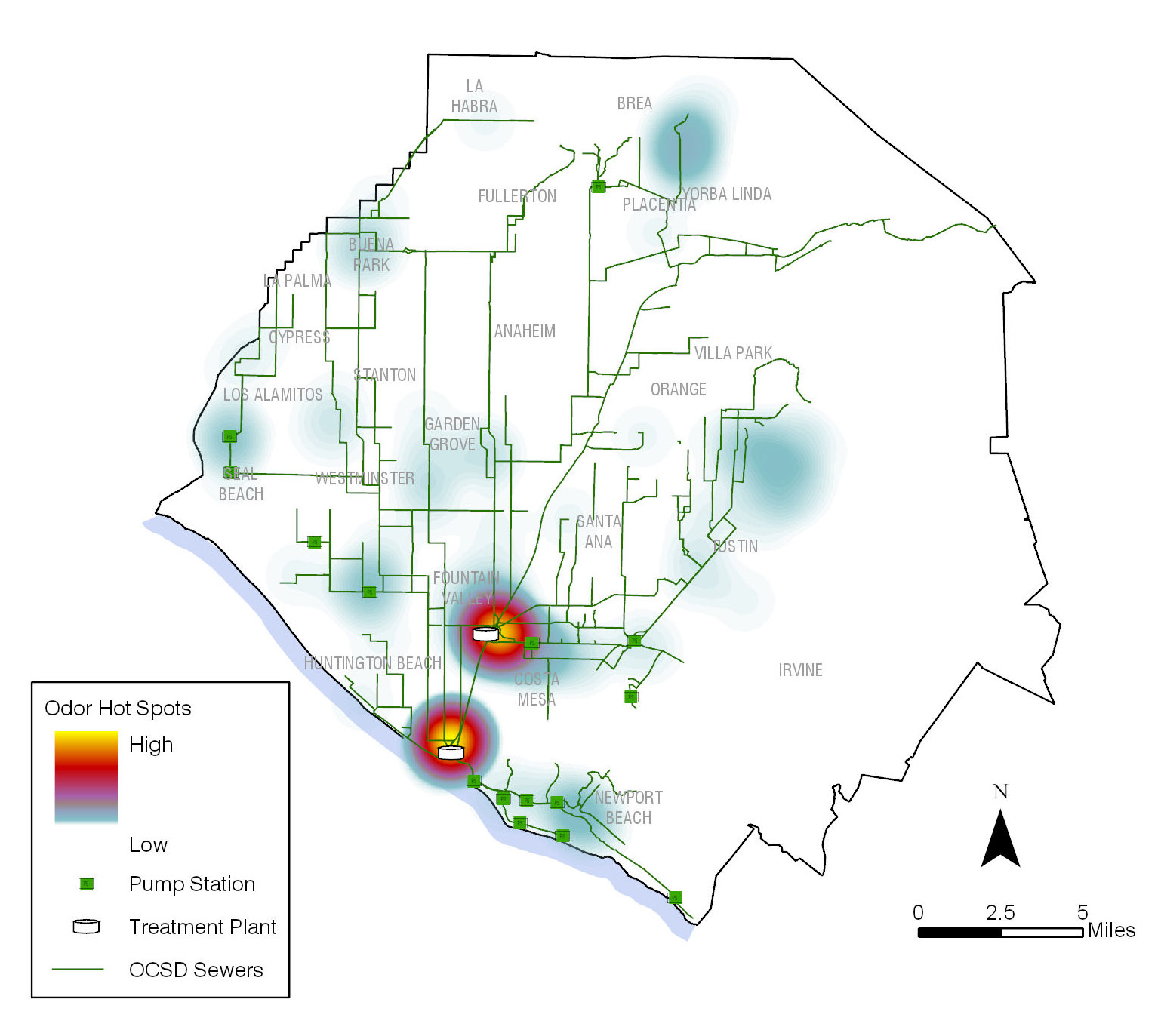

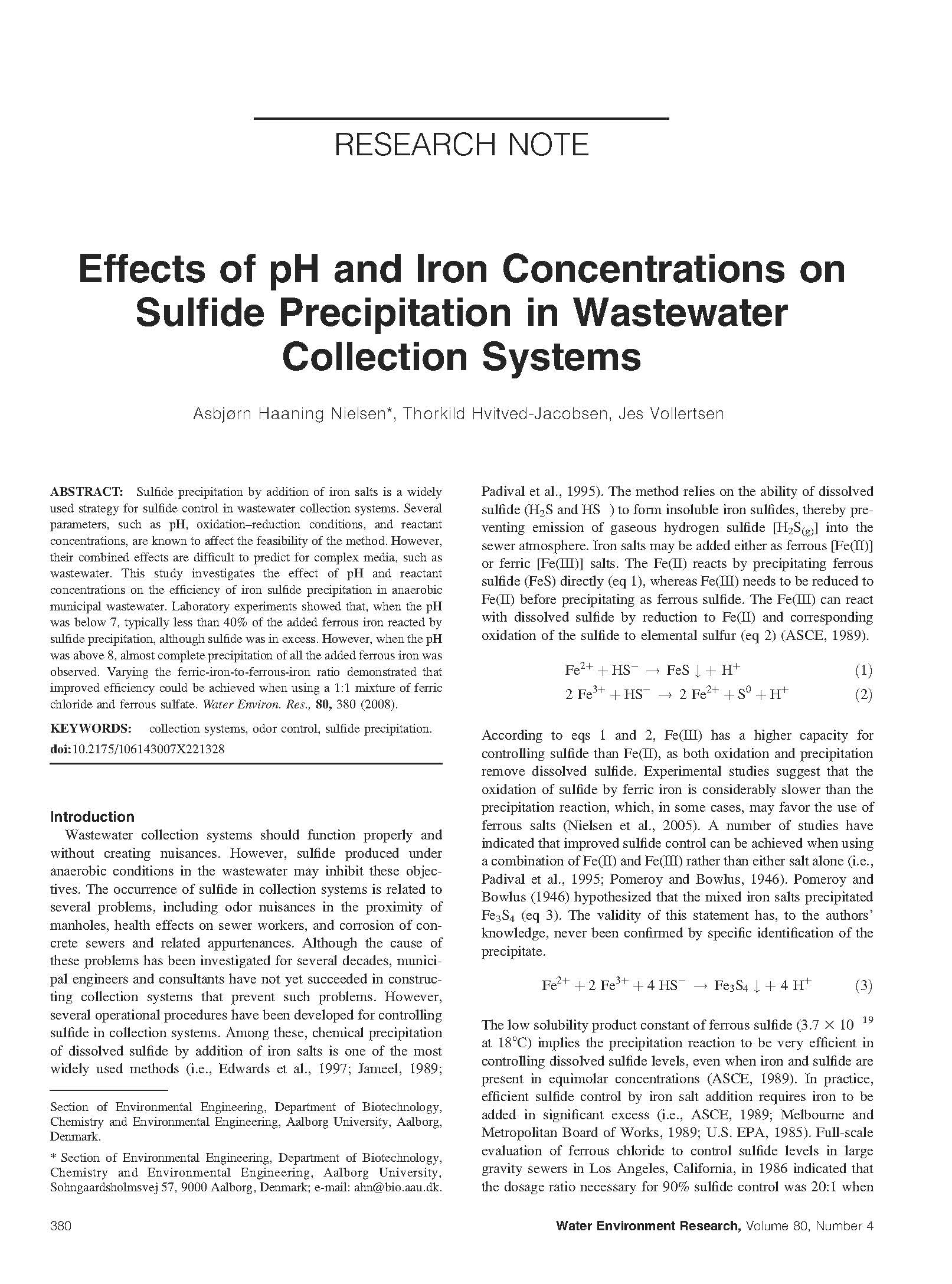

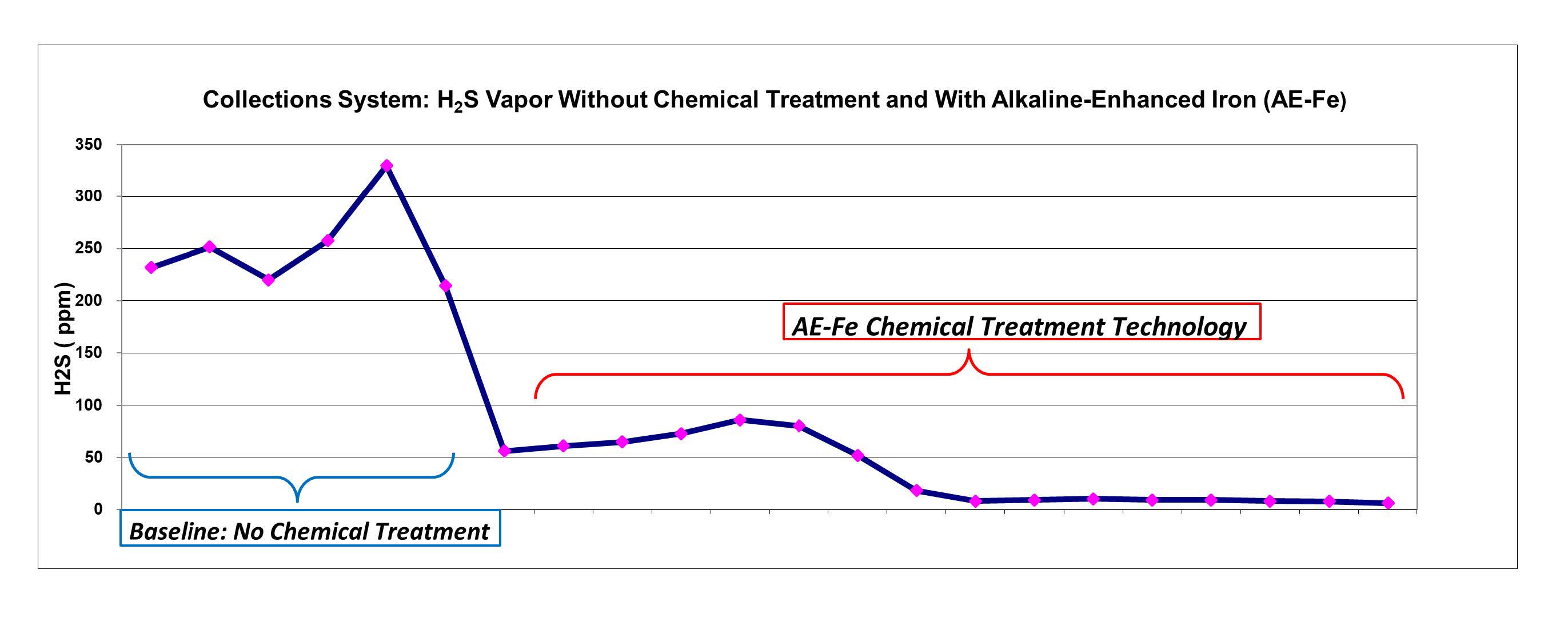

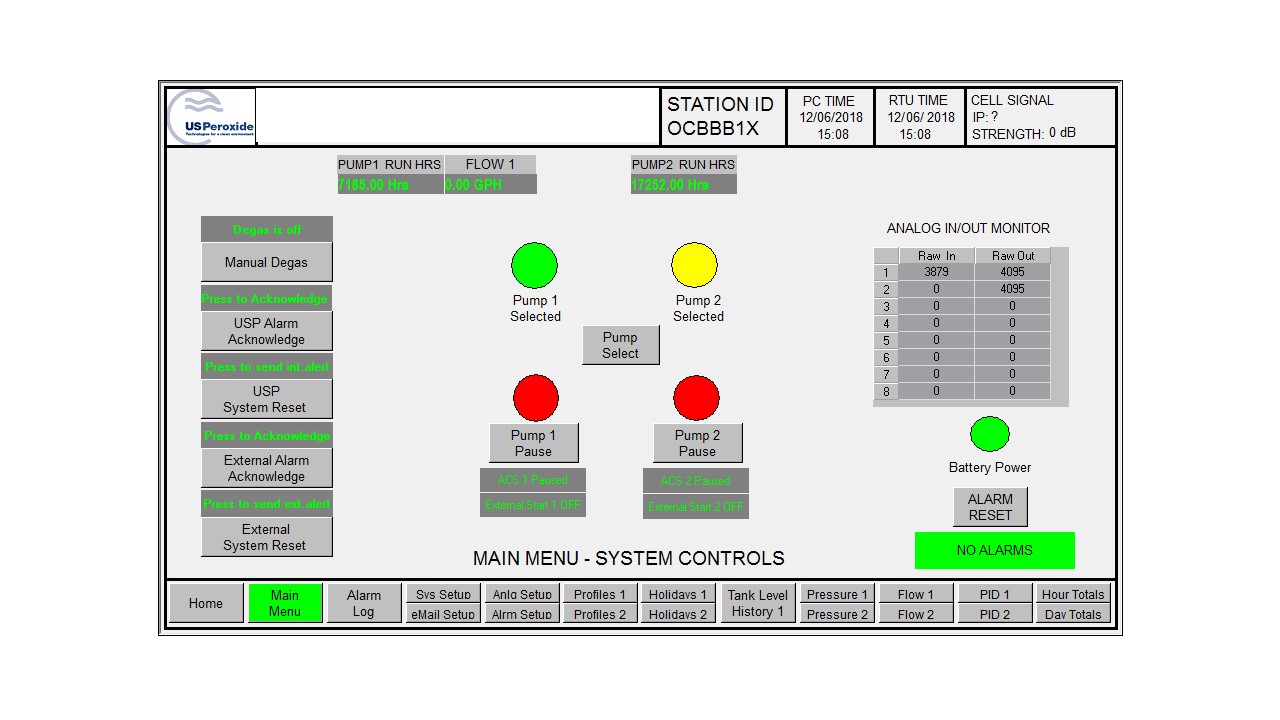

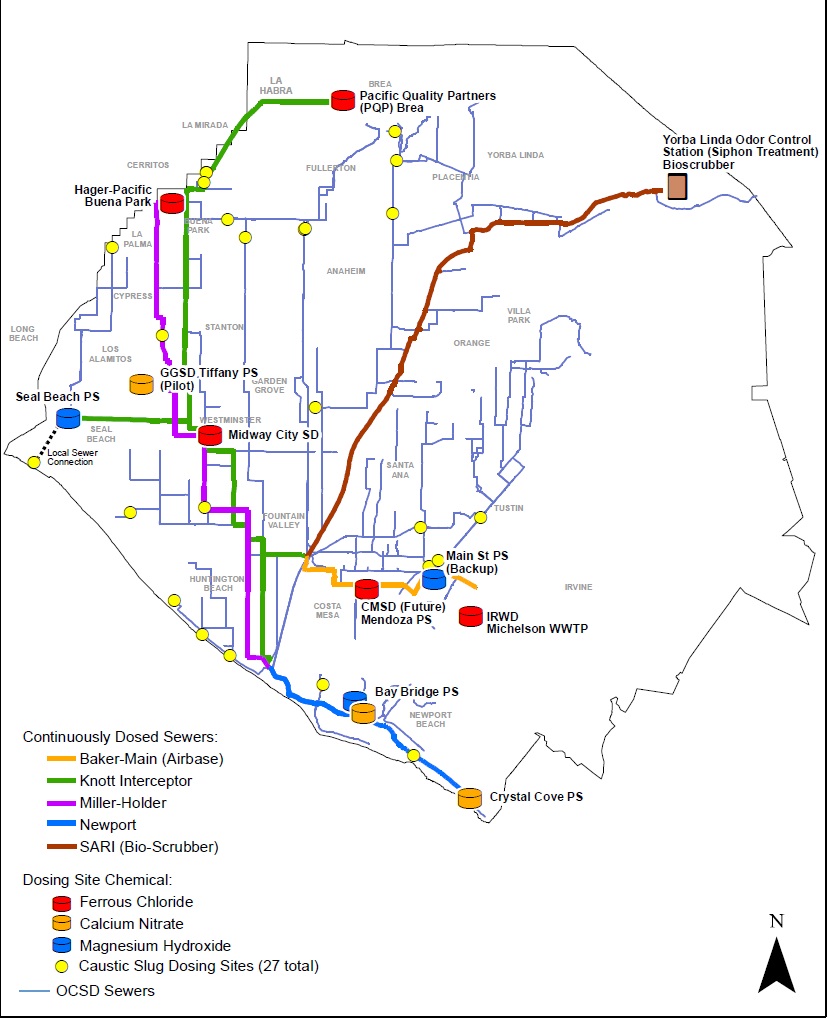

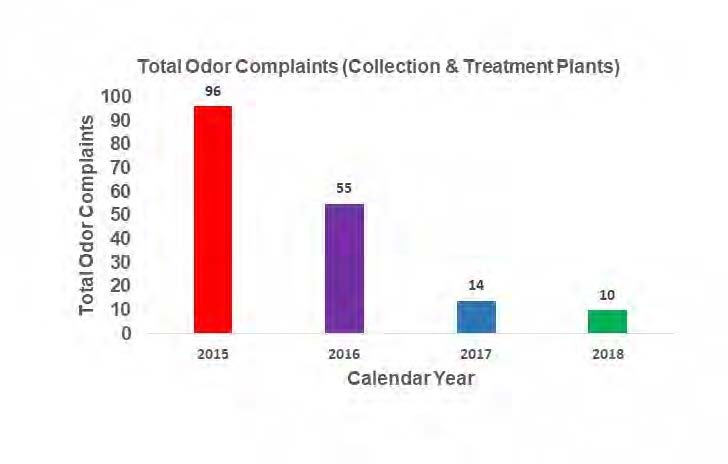

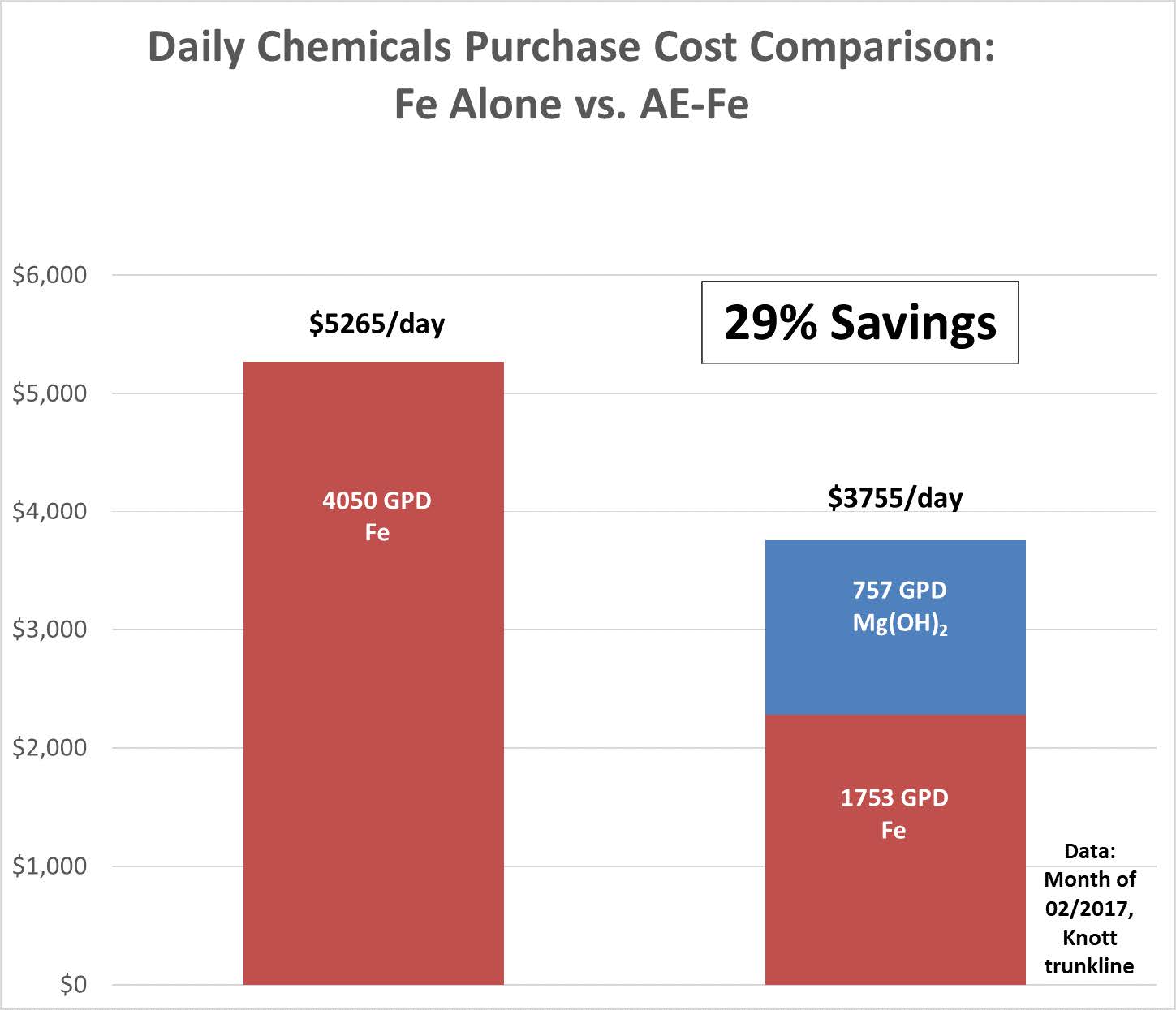

Superior Achievement in Environmental Engineering and ScienceCategory Entered: Operations/ManagementMultipronged Collection System Odor Control Program at OCSD; Less Odors and Lower CostsEntrant: Orange County Sanitation District Entrant Profile The Orange County Sanitation District (OCSD) is a special district governed by a 25- member Board of Directors comprised of 20 cities, four special districts, and one representative from the Orange County Board of Supervisors. OCSD provides wastewater collection, treatment, and recycling for approximately 2.6 million people living within a 479-square-mile area of central and northwestern Orange County, California (CA). Our facilities include 396 miles of sewer pipes, located throughout the county. Each day we treat approximately 185 million gallons of wastewater from residential, commercial, and industrial sources that is sent to our two treatment plants: Plant No. 1 in Fountain Valley and Plant No. 2 Huntington Beach, CA. Located in the second most densely populated county in the state, OCSD has operated since 1954 and is the third largest wastewater agency west of the Mississippi River. Also, Orange County is the third most populous county in the state, and the sixth most populous county in the Unite States. The treatment of wastewater is inherently an odorous process. To combat the persistent odors and to be good neighbors, OCSD has implemented several operational and process improvements using a combination of innovative and well- established odor control strategies to reduce public odor complaints. Project DescriptionThe conveyance and treatment of wastewater is a naturally odorous process. The public rightly expresses concern about, and intolerance of, noxious odors from wastewater facilities, including the collections systems that run through residential neighborhoods and business districts. The Orange County Sanitation District (OCSD) has developed an extensive collection system odor control program that combines optimized chemical treatment using a patent-pending process. It includes continuous dosing optimization using state-of-the-art data collection and process control, and proven mechanical abatement techniques to minimize fugitive odor emissions throughout its extensive service area. In addition to its two large wastewater treatment plants, OCSD is responsible for 396 miles of sanitary sewers and 15 offsite pump stations. Liquid-phase odor control that maintains average vapor-phase hydrogen sulfide below 25 parts per million (ppm) reduces odors and corrosion in the regional trunk system and suppresses odors at the treatment plants. Frequent dosing of single chemicals (e.g., ferrous chloride (FeCl2), magnesium hydroxide (Mg(OH)2) sodium hydroxide, calcium nitrate) is common in the industry. OCSD generally used ferrous chloride and magnesium hydroxide more than others because ferrous chloride is effective against hydrogen sulfide (H2S), and magnesium hydroxide targets a wide range of other compounds. But in its efforts to reduce overall chemical usage and also achieve lower net costs, OCSD needed to use the best characteristics of both chemicals synergistically. Building on a Research Note published in Water Environment Research (80, 380 (2008)), OCSD developed an optimized technology dubbed Alkaline-Enhanced Iron (AE-Fe), which is based on ferrous iron in wastewater reacting with dissolved sulfide to form insoluble iron sulfide, which prevents emissions of gaseous hydrogen sulfide. The effectiveness of the reaction depends on pH: a pH less than 7 will provide only 40% precipitation efficiency, while a pH at or near 8 will yield nearly complete precipitation. In AE-Fe, the wastewater pH is increased by adding magnesium hydroxide, which shifts the proportion of hydrogen sulfide toward the liquid phase. OCSD has demonstrated that elevating the wastewater pH to at least 8 allows the same amount of iron dosing to achieve lower liquid- and vapor-phase sulfide concentrations. At lower total iron concentrations, comparable hydrogen sulfide control is realized, thus reducing iron costs and incoming solids loadings to the treatment plant. This is the subject of OCSD's pending patent (application No. 13/247138). AE-Fe treatment efficiency is optimized through remote telemetry and dosing control designed specifically for each site's chemical mix, feed rate requirements, and desired delivery frequency. Every site includes a monitoring and control system platform to support remote inventory management and customized dosing profiles that can be changed to reflect historical and anticipated process conditions. Chemical dosing optimization is supported by other parts, both high- and low-tech, of a multipronged odor control program. Odor complaints from the public are continually tracked and visualized on GIS maps that allow any odor "hot spots" to be identified and corrected quickly, An FLIR optical gas imaging camera is used to pinpoint invisible odor sources. Low-tech elements include manhole biofilters, interceptor sewer gas flaps, and even stringent QA/QC protocols for the treatment of chemicals. Integrated ApproachAir: Air quality is improved by reducing the releases of fugitive odors from wastewater conveyance and treatment. Public odor nuisances are avoided. Water: Odor control is achieved without increasing the use of potable water or negatively impacting water sources or watersheds. Odor control supports the overall process of wastewater treatment, which is necessary to protect receiving waters and promote water reclamation and reuse. Land: Inorganic components of odor treatment chemicals (such as iron) add to the solids loading of a treatment plant and ultimately to the residual solids that are land applied or landfilled. Reduced chemical usage reduces the land impacts of wastewater treatment. QualityThe effectiveness and quality of the odor control program is shown by the dramatic decrease in odor complaints received during the past two years while also reducing chemicals costs. OCSD's stated goal is to have no more than 12 complaints annually from its 479 square mile service area. Since 2015, complaints have been reduced 90% to a total of 10 complaints in 2018. The cost savings with AE-Fe are evident in representative data from February 2017. Uncontrolled vapor-phase H2S (350 ppm) would have been reduced 95% with iron alone and was reduced 98% with AE-Fe with 29% lower chemicals costs. The 3,905 lb/day iron that were not used id not add to OCSD's residual biosolids, saving hauling costs of $900/day more.

Originality and InnovationThe centerpiece of the multipronged odor control program is the patent-pending AE-Fe technology and its implementation with advanced telemetry and process control features. Accompanying this is GIS-based complaint tracking and state-of- the-art odor source imaging, supplemented by physical barriers and biological filters to minimize fugitive odors throughout an extensive regional collection system. ComplexityOCSD's 396-mile collection system serves residential, commercial, and industrial customers. The wastewater characteristics and flow profile in any given trunk line are impacted by water conservation measures, periodic drought conditions, changes in industrial dischargers in the service area, and flow diversions for the Groundwater Replenishment System's indirect potable reuse. In addition, OCSD receives desalter concentrate and industrial and domestic wastewater from the upper Santa Ana River Basin and sludge from the Irvine Ranch Water District's treatment plant. These factors combine to make odor control requirements throughout the system site- specific and very dynamic. Contribution to Social or Economic AdvancementThere is public intolerance of odors associated with wastewater treatment operations. This is codified in the local air quality regulators' nuisance prohibition ["A person shall not discharge from any source whatsoever… air contaminants…which cause injury, detriment, nuisance, or annoyance…to the public…" (SCAQMD Rule 402)]. Social Advancement: OCSD's odor mitigation program has dramatically decreased odor nuisances in one of the most densely populated areas of California, allowing residents to enjoy the region's natural resources and improving their quality of life. Economic Advancement: An efficient and optimized program provides effective odor control while decreasing operational costs. This reduces the costs to our ratepayers, which helps stimulate the local economy. Click images to enlarge in separate window. Click here to return to the list of 2019 winners. |