- Home

- Contact Us

- News & Events

- Awards

- AAEES Awards Criteria

- 40 Under 40 Recognition Program

- Edward J.Cleary Award

- Excellence in Environmental Engineering and Science Education

- Gordon Maskew Fair Award

- Honorary Member

- International Honorary Member

- Ralph and Joe Bales Graber Science Award

- Stanley E. Kappe Award

- Environmental Communications Awards Competition

- Excellence in Environmental Engineering and Science Competition

- The AAEES Chapter Blue Marble Award

- Resources

- AAEES Microcredentials

- Annual Reports

- AAEES Press Releases

- AAEES Website How To VIdeos

- Environmental Engineer and Scientist

- Environmental Engineering Body of Knowledge

- PFAS Resources

- Specialty Examination Guide

- Students and Young Professionals Resources

- Who's Who in Environmental Engineering & Science®

- Leadership Opportunities

- Membership

- Donate

- Jobs

2019 Excellence in Environmental Engineering and Science® Awards Competition Winner

Honor Award - Small ProjectsDevelopment of Floating Solar for use in Reservoir and Coastal Marine ConditionsEntrant: Housing & Development Board Entrant Profile The Housing & Development Board (HDB) is Singapore's public housing authority. We plan and develop Singapore's housing estates; building homes and transforming towns to create a quality living environment for all. We provide various commercial, recreational, and social amenities in our towns for our residents' convenience. As the public housing agency that houses over 80% of Singapore's population, HDB has a key role in supporting Singapore's commitment to sustainable development. In 2011, HDB successfully invented and implemented an innovative modular floating wetlands system along the Punggol Waterway. HDB has been spearheading solar initiatives and accelerating solar adoption island wide over the past 10 years. In land-scarce Singapore, there is a need to explore new areas to harness solar energy. HDB collaborated with M/S Million Lighting Co Pte Ltd and Assoc Prof Ang Kok Keng from National University of Singapore (NUS) to explore the idea of floating solar system. In May 2018, HDB piloted a 100 Kilowatt Peak (KWp) floating solar system in Tengeh Reservoir, Tuas. This system can generate approximately 120 MWh of electricity and can reduce carbon emissions by 60 tonnes annually. This one-of-its-kind floating system can be easily assembled and deployed in both reservoir and coastal marine conditions. HDB is also working with M/S ISO-Landscape Pte Ltd and NUS to scale up the implementation and deploy the first large scale offshore floating solar system of approximately 5 Megawatt Peak (MWp) in 2019. The floating system is designed to overcome the challenges of stronger waves and wind conditions, as well as weight of biofouling and corrosion. This system has an area of approximately 50,000 m2 or equivalent to five soccer fields, and is estimated to generate about 6,000 MWh of electricity and can reduce carbon emissions by 3,000 tonnes in a year. Project DescriptionDemonstration of a comprehensive, integrated approach that considers all environmental media, i.e., air, water, and land. For example, solution of an air pollution problem must not create a land disposal problem or an adverse water impact that is not addressed by the project.In 2015, Singapore pledged to reduce our Emissions Intensity (EI) by 36 per cent from 2005 levels by 2030, and stabilise emissions with the aim of peaking around 2030. Our strategies to achieve our 2030 pledge is to reduce carbon emissions in power generation. Singapore does not have many alternative renewable energy options and solar energy is presently the most technically and economically-viable option. Through the SolarNova programme, the Housing & Development Board (HDB) will progressively roll out 220MWp of Solar panels across 5,500 HDB residential blocks, which will align with Singapore's plans to generate 350MWp of solar power by 2020. Beyond 2020, Singapore has set an ambitious target to increase adoption of solar energy to 1GWp. However, as solar energy generation is dependent on surface area, Singapore's land constraints remain a challenge. Hence, harnessing solar energy in more innovative and efficient ways, such as floating solar PV on our reservoirs and surrounding seas, will help Singapore achieve its solar deployment plans. The development of Floating Solar System (FSS)- Figure 1 supports Singapore's strategy in reducing carbon emissions in power generation. Being designed for deployment in both reservoir and coastal marine environment, the FSS system is able to tap the sun' s boundless energy and vast surface area of waterbody as alternative energy clean source for Singapore. The materials used for the floating system are environmentally friendly and recyclable, and the deployment does not affect water quality and biodiversity. The complexity of the problem addressed.As the first locally-designed floating solar system, the development of FSS has overcome several complex engineering challenges as follows.

The FSS has demonstrated several unique advantages over the other systems in the world's largest floating solar photovoltaics cell test-bed in Tengeh Reservior. Some of the key features of the FSS are:

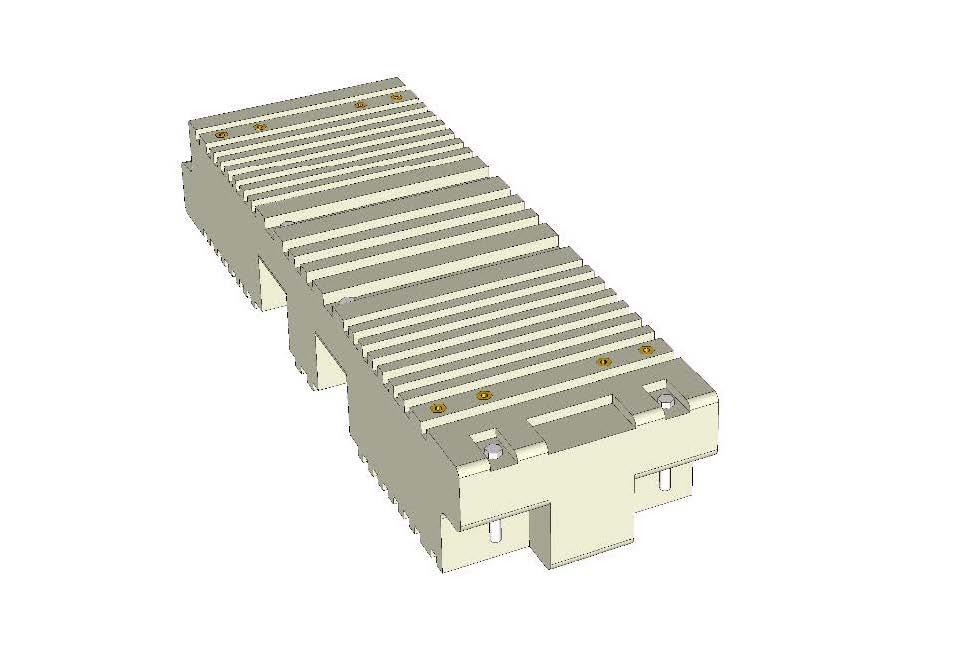

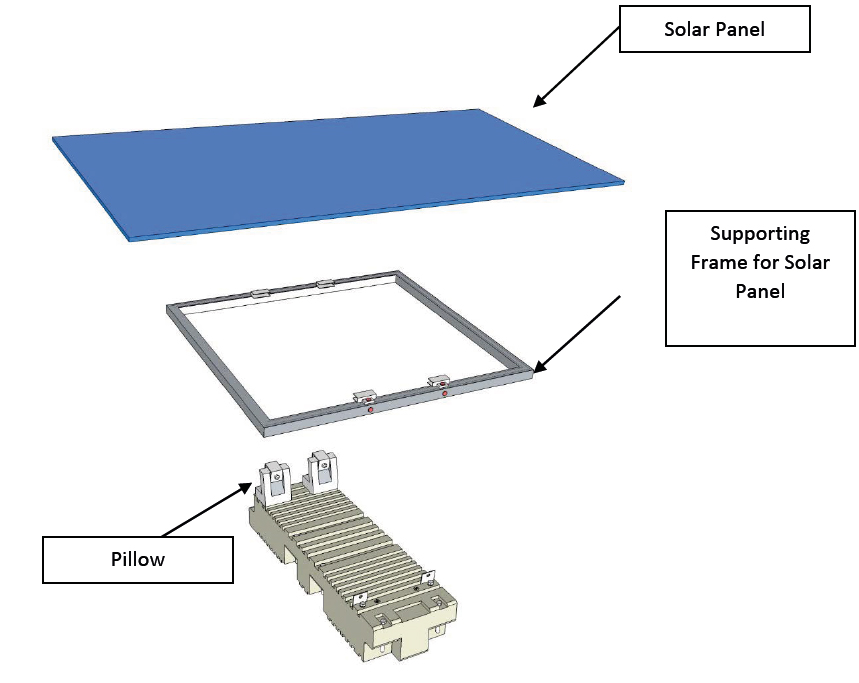

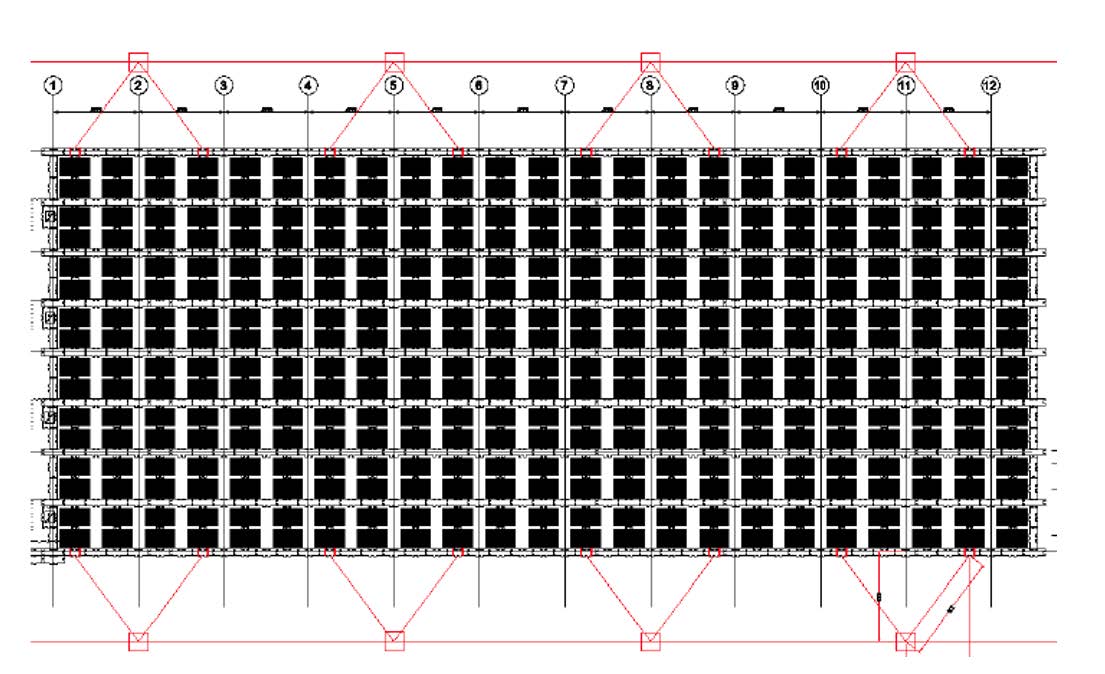

Originality and innovation, representing the application of new knowledge, a new application of existing knowledge, or an innovative mix of existing knowledge.The development of the Floating Solar System (FSS is a further extension of HDB's effort in floating structure development. In 2011, HDB successfully invented and implemented an innovative modular Floating Wetlands System (FWS) deployed along the Punggol Waterway. Through the development, HDB also invented and patented a unique interlocking solution that enhanced the rigidity and stability of the modules. As the solution is practical and can be scaled up easily, several local SMEs and Institutions of Higher Learnings (IHLs) have approached HDB to collaborate and expand the applications of the floating module to other areas. From a floating wetland system that evolves to a floating solar system, the development of FSS demonstrates creativity in innovation, design and the ability to push the boundary of innovation and research. HDB has filed for patent for the corrugated surface and interlocking design for the floating module in April/May 2018 in Singapore and India. HDB plans to file patent in Malaysia, Thailand, Hong Kong and China in 2019. Design innovation focus on both the micro design of module and macro layout of the entire floating solar system using Static and Hydroelastic Analysis. Some of the key considerations in designing the floating modules include the stability of the system and ease of maintenance. Each rectangular module is designed with a row of grooves and ridges which serve as structural elements to provide rigidity and strength (Refer to Figure 2), so that the module can carry the imposed loading of up to 75Kg due to operation and maintenance activities effectively. The corrugated surface is also cambered to drain off water so as to minimize ponding of water, which may lead to breeding of mosquitoes. On each side of the floating module, there are at least two connectors that can be bonded to another floating module with stainless steel pins. The interlocking inter-modular connection ensures a safe and stable maintenance walkway. There is also flexibility within the connections, which enable the entire floating solar system to withstand oncoming waves and winds. Detailed floating module accounting for various loading conditions and load patterns were carried out. A nonlinear finite element model for the inter-modular connection was also constructed and the stiffness of the connector was investigated through load-response analyses. The computed connection stiffness was then used in a global model of the PV farm (Refer to Figure 5) to derive the forces and moments developed at the inter-modular connectors. Finally, the serviceability and strength of the connectors were checked using the nonlinear connector model. This modular floating system can be deployed in reservoir and coastal marine condition and the design can be modified to suit the environment. Some of the key achievement and plans for the FSS are:

By End 2019, publication of technical paper in international journal to share with the industry on the design approach and deployment of FSS The extent to which the project contributes to or offers the prospect of contributing to social or economic advancement.The Committee on the Future Economy outlined seven strategies for Singapore to stay ahead in a challenging global climate. Some of the strategies include:

The development of the first locally designed floating solar system FSS has benefited government agencies, local industry and academia. This is a trans-disciplinary research project that involved the different disciplines (Environmental, Civil & Structural, Mechanical & Electrical Engineering, material and manufacturing technologies) working in close collaboration to build up new engineering capabilities and skills. For example, HDB and its business partner acquired new skills from NUS on the design of floating system using Finite Element Analysis, and there is transfer of engineering knowledge from the manufacturer to all collaborators on the manufacturing processes for the floating system. In supporting the strategies outlined by the Council, the development of FSS has achieved the following milestone:

Quality as evidence by the degree of user satisfaction and proven performance.The project team conducted guided tours at the Tengeh Reservoir and shared with various stakeholders on the design and benefits of the floating solar system (FSS). Six enterprises have expressed strong interest on the design, and the HDB is exploring with these enterprises to deploy the floating solar system in local and overseas projects. These companies evaluated the design of floating system and found that it is lightweight, strong, cost effective and easy to deploy on a large-scale basis. The anchoring system also does not require heavy machineries to install. The project team also carried out rigorous structural tests on the loading capacity of the floating modules and its connectors at a factory and on site, and concluded it is able to carry up to 75 kg per module. There is also no permanent deformation being observed for the floating module and its connectors. In addition, the tests also showed that it passed the stringent requirement for connector stiffness and connector loading capacity. The overall layout of the floating solar system is also proven that it is able to withstand waves and wind and water current speed in the reservoir, as there are no visible damages to the floating solar system and its since May 2018. The global behavior of the FSS with regards to vertical displacement is also within design requirement. The floating modules are also durable and there are no visible cracks due to loadings and ultraviolet. In addition, the material used for the floating modules does not affect the water quality. The project team has also carried out a survey on the receptiveness of members of the public with over 240 members of public, and over 97% think that the deployment of floating solar in reservoirs and surrounding seas of Singapore is a good initiative, and over 96% would like to see more floating solar to be deployed in Singapore. Click images to enlarge in separate window. Click here to return to the list of 2019 winners. |