- Home

- Contact Us

- News & Events

- Awards

- AAEES Awards Criteria

- 40 Under 40 Recognition Program

- Edward J.Cleary Award

- Excellence in Environmental Engineering and Science Education

- Gordon Maskew Fair Award

- Honorary Member

- International Honorary Member

- Ralph and Joe Bales Graber Science Award

- Stanley E. Kappe Award

- Environmental Communications Awards Competition

- Excellence in Environmental Engineering and Science Competition

- The AAEES Chapter Blue Marble Award

- Resources

- AAEES Microcredentials

- Annual Reports

- AAEES Press Releases

- AAEES Website How To VIdeos

- Environmental Engineer and Scientist

- Environmental Engineering Body of Knowledge

- PFAS Resources

- Specialty Examination Guide

- Students and Young Professionals Resources

- Who's Who in Environmental Engineering & Science®

- Leadership Opportunities

- Membership

- Donate

- Jobs

2019 Excellence in Environmental Engineering and Science® Awards Competition Winner

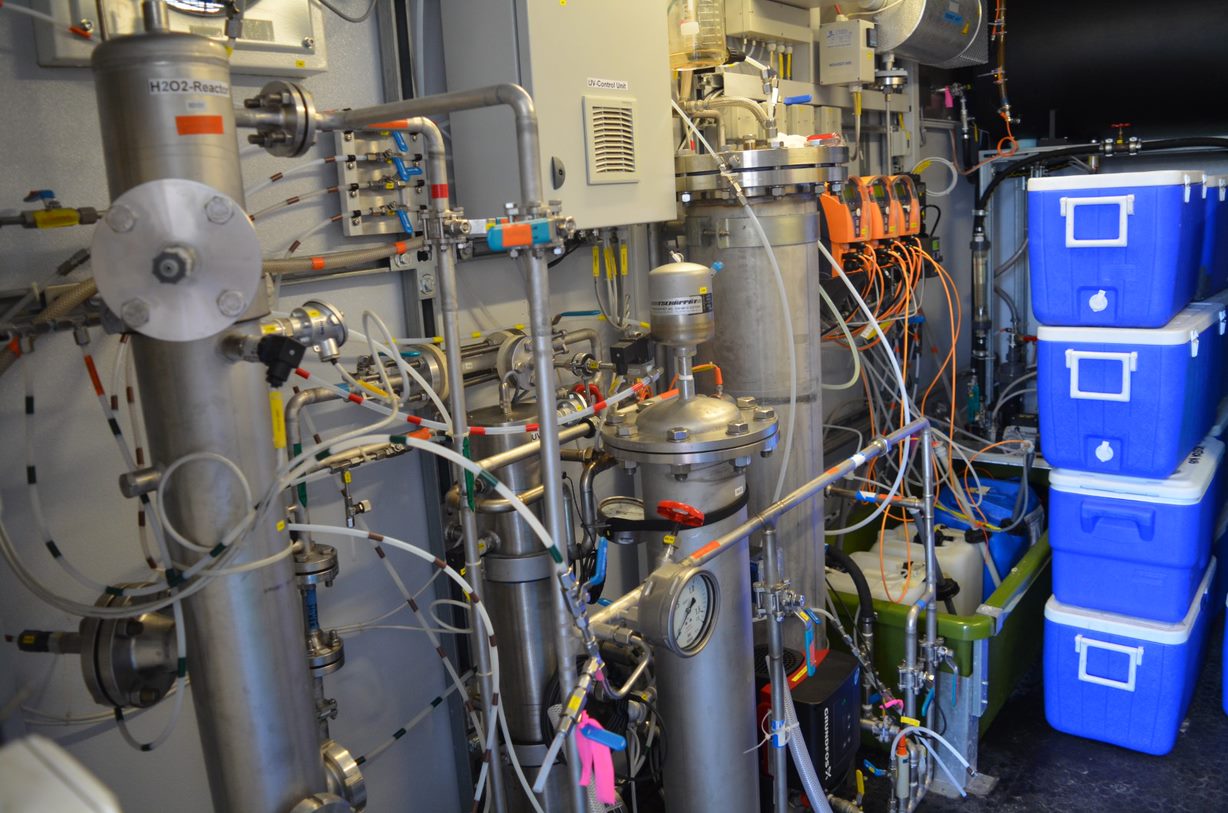

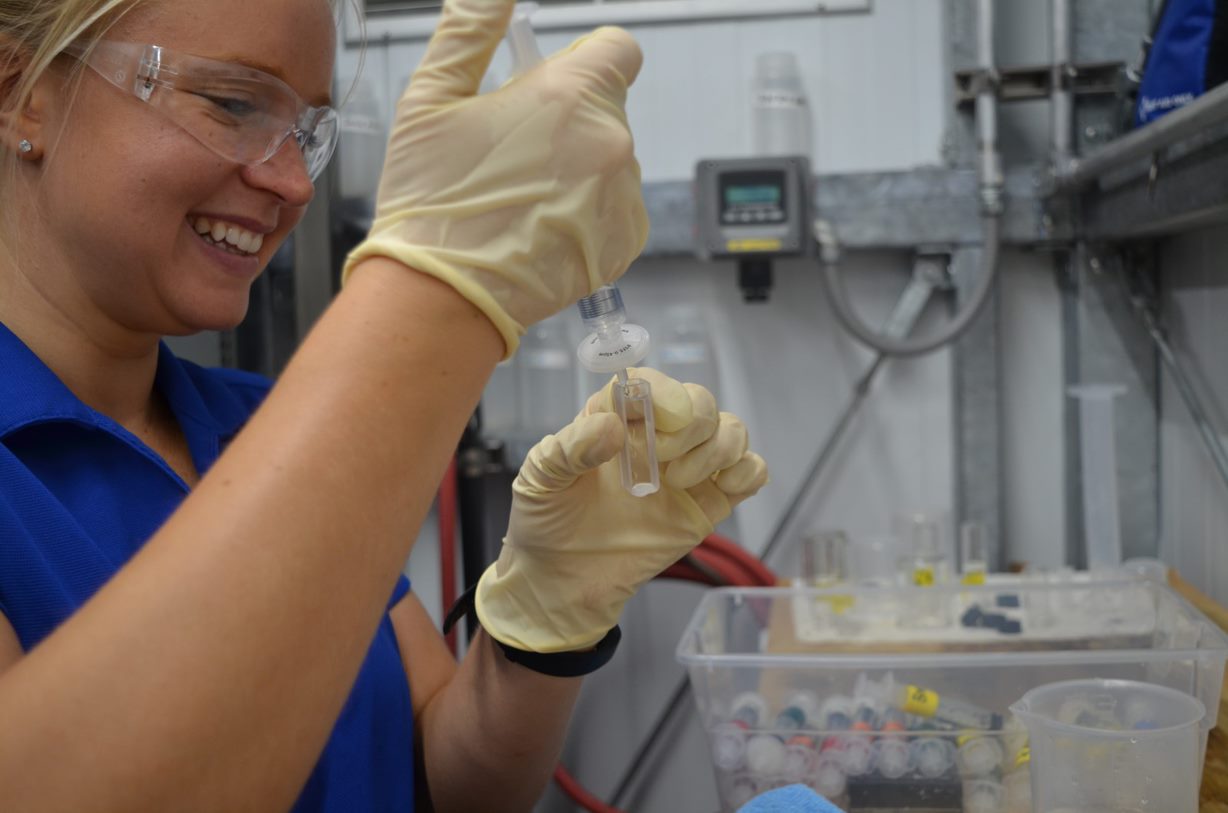

Honor Award - ResearchWater Purification Technology Evaluation and R&D Testing ProjectEntrant: CDM Smith Entrant Profile JEA is the eighth largest community-owned utility in the United States and Florida's largest community-owned utility, providing water, sewer and power services to over 330,000 customers in the Jacksonville area. JEA implemented a water purification technology (WPT) program to explore new ways to prepare for the area's future water supply needs through indirect potable reuse. Phase I of the program is the WPT Evaluation and Research and Development (R&D) Testing Project, which tested two leading technologies for water purification and provided a roadmap for future phases of the project, including a Phase II demonstration facility and Phase III full-scale facility. JEA selected CDM Smith to conduct the research project. CDM Smith is a full-service engineering and construction firm that provides lasting and integrated solutions in water, environment, transportation, energy and facilities to public and private clients worldwide. CDM Smith's staff provided all R&D plant operational services, including equipment procurement, start-up and commissioning, water quality sampling and final data reporting. Plant operators worked closely with equipment providers, including Wigen Water Technologies, Intuitech Inc., and Suez Water Technologies to ensure 24/7 operations throughout the 10-month study. Eurofins Eaton Analytical LLC performed both weekly and monthly water quality analyses of over 250 regulated and non-regulated parameters. The Dalton Agency, New Water Resources and Katz and Associates helped JEA and CDM Smith develop an outreach campaign geared toward public education and acceptance. Through the partnership of these stakeholders, JEA is providing leadership and driving innovation for potable reuse in Florida. Project DescriptionInterest in water reuse technologies is growing as the demand for potable water approaches the limit of conventional water supplies. The Floridan aquifer is the primary water supply for over 330,000 customers in Jacksonville, Florida. With a growing population and economy, potable water demands are anticipated to increase. The local utility company, JEA, proactively launched a three-phased, multi-year water purification technology (WPT) program to evaluate potable reuse for aquifer recharge. Phase I of JEA's program is research and development (R&D) to evaluate and compare the treatment performance of two competing water purification technologies:

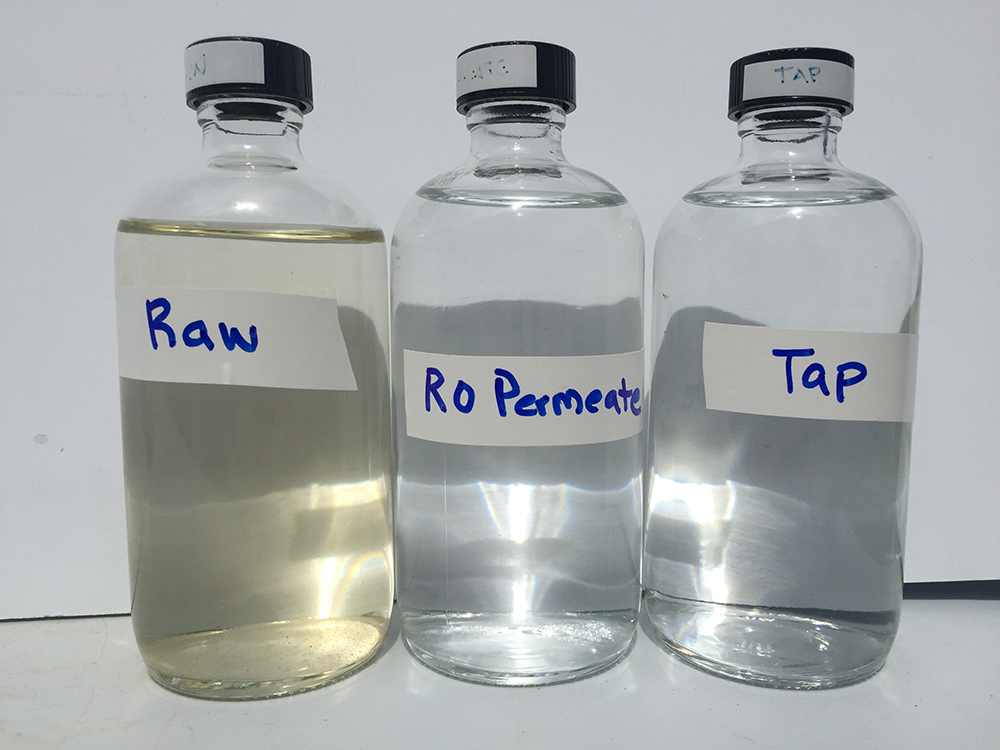

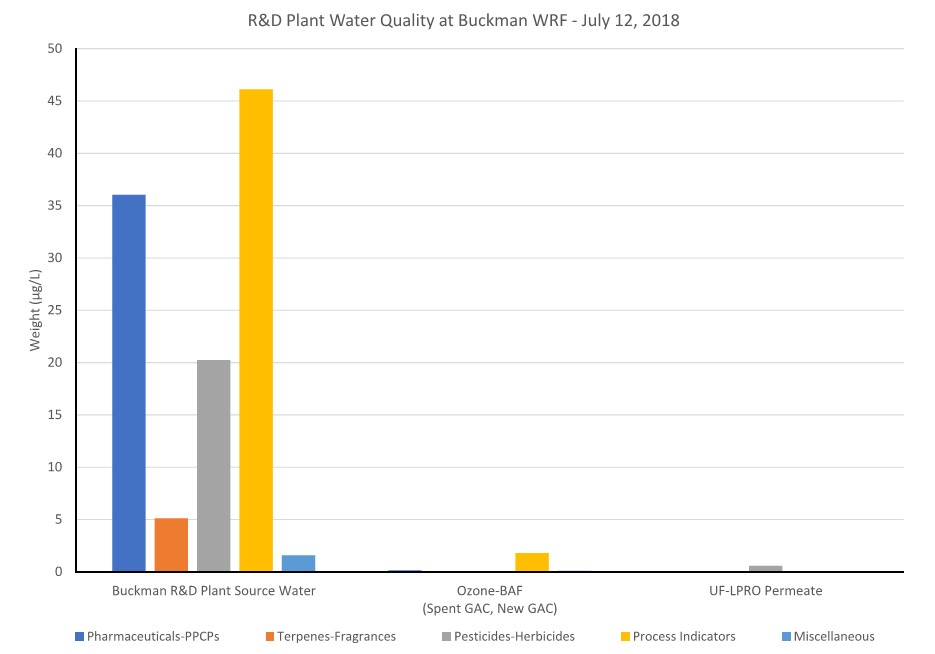

These two systems operated in parallel at two different water reclamation facilities (WRFs) for approximately 5 months each. Phase I culminated in the identification of the most technically and economically viable treatment process for JEA's subsequent phases of the program: UF-LPRO-AOP. Phase II will implement the selected process for a 0.5-million-gallon-per-day (mgd) demonstration facility. Phase III involves a commercial-scale facility, producing 10-50 mgd of purified water. An Integrated ApproachA turnkey R&D system delivered comprehensive results for JEA. This included design of both treatment systems, full procurement of the R&D plant equipment, and development of an experimental design and testing protocol for a variety of conditions at two WRFs. CDM Smith staff provided all R&D plant operational services, including start-up and commissioning at both WRFs, water quality sampling, and additional operational support beyond basic troubleshooting and maintenance necessary for continuous operation. In addition to monitoring approximately 77 regulated contaminants, more than 250 unregulated parameters were analyzed during sampling events to provide a comprehensive assessment of the source and purified water quality. Quality ResultsThorough testing and organization ensured quality. CDM Smith provided detailed project planning and schedules, test protocols, experienced operations staff, and a comprehensive data reporting criteria modification process. The project team worked closely with JEA staff to understand operations at the full-scale WRF to overcome challenges associated with potable reuse R&D piloting. Dual-facility testing strategy yielded decisive treatment observations. The R&D facility was tested at two WRFs to directly evaluate treatment performance with two distinctly different wastewater effluents. The Southwest WRF was considered more traditional with primarily domestic sources, while the Buckman WRF treated daily influxes of landfill leachate and received significant flows from industrial users across a range of sectors, including the fragrance industry and steel manufacturing industry. Conclusions

Data from Phase I allowed JEA to optimize the treatment processes and provided critical design and operational information for future WPT facilities. Due to the characteristics of the source waters tested, the UF-LPRO-AOP process produced higher quality purified water compared with the Ozone-BAF-AOP process, exhibited more reliable operation and was less subject to variations in source water quality. Based on this comparison and lifecycle cost estimates, CDM Smith recommended the UF-LPRO-AOP system for future phases of the WPT program. Originality and InnovationPioneering study enhances the potable reuse industry's grasp of two leading technologies by testing them side-by-side at two different WRFs. The Ozone-BAF-AOP treatment process, while widely used in the drinking water industry, is just beginning to warrant consideration in the potable reuse arena. The primary advantage of the Ozone-BAF-AOP treatment system compared with UF-LPRO-AOP is that Ozone-BAF-AOP does not produce concentrate. The cost and environmental concerns associated with concentrate management can impose limitations for some utilities. Multi-year outreach campaign gained public trust. Earning and maintaining the community's trust as it relates to water supply and public health is a top priority. CDM Smith helped JEA develop a rigorous, multi-year public outreach campaign early in Phase I to clearly explain the treatment processes and safeguards for protecting public health. More than 250 people toured the R&D plant, including elected officials, university students, regulatory agencies, water operators from neighboring counties and local news agencies. A baseline JEA customer survey performed by CDM Smith and the Dalton Agency gauged the community's understanding and attitude towards potable reuse. Surveys will continue to be used throughout the WPT program. Complexity of the ProblemCustom, 22-week plan ensured sound testing of each process system and individual parameters. Carefully selected conditions for each unit process maximized data collection to achieve primary test objectives, demonstrate the efficacy and robustness of individual unit process, and optimize parameters that significantly influence capital and/or operations and maintenance (O&M) costs (e.g., chemical dosages, overflow rates, media type, flux rates, operating pressures). To understand which water purification process systems met water quality goals for aquifer recharge, a thorough water quality sampling plan was developed to fully characterize the nature of the source and treated water, including a suite of regulated and non-regulated parameters (e.g., terpenes and fragrances, pharmaceuticals, pesticides and herbicides). Contribution to Social or Economic AdvancementWPT program underscores importance of aquifer recharge to United States water supply sustainability. Florida state legislators, the Florida Department of Environmental Protection, Florida's water management districts, and local municipalities and utilities have realized the need for alternative water supplies and are working to enact policies that will help expand potable reuse. This project demonstrates the feasibility of integrating alternative water supplies, such as indirect potable reuse, into a diverse portfolio of water resource supply options. Additional benefits of JEA's WPT program included more integrated planning, improved environmental sustainability and an informed public. What's next? R&D testing concluded in September 2018 with the selection of UF-LPRO-AOP for Phases II and III. CDM Smith recently published the final technical report, which documents the testing, water quality results, capital and O&M cost estimates, and provides a recommended strategy for full-scale implementation. Click images to enlarge in separate window. Click here to return to the list of 2019 winners. |