- Home

- Contact Us

- News & Events

- Awards

- AAEES Awards Criteria

- 40 Under 40 Recognition Program

- Edward J.Cleary Award

- Excellence in Environmental Engineering and Science Education

- Gordon Maskew Fair Award

- Honorary Member

- International Honorary Member

- Ralph and Joe Bales Graber Science Award

- Stanley E. Kappe Award

- Environmental Communications Awards Competition

- Excellence in Environmental Engineering and Science Competition

- The AAEES Chapter Blue Marble Award

- Resources

- AAEES Microcredentials

- Annual Reports

- AAEES Press Releases

- AAEES Website How To VIdeos

- Environmental Engineer and Scientist

- Environmental Engineering Body of Knowledge

- PFAS Resources

- Specialty Examination Guide

- Students and Young Professionals Resources

- Who's Who in Environmental Engineering & Science®

- Leadership Opportunities

- Membership

- Donate

- Jobs

2019 Excellence in Environmental Engineering and Science® Awards Competition Winner

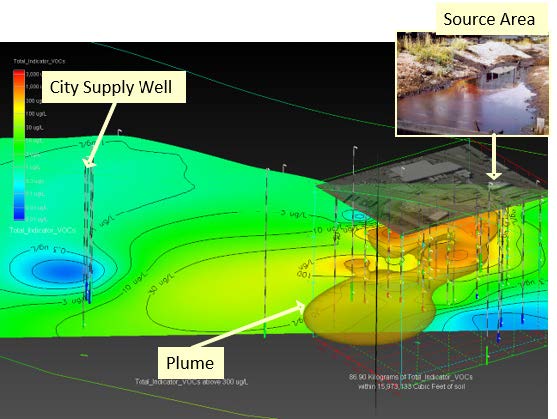

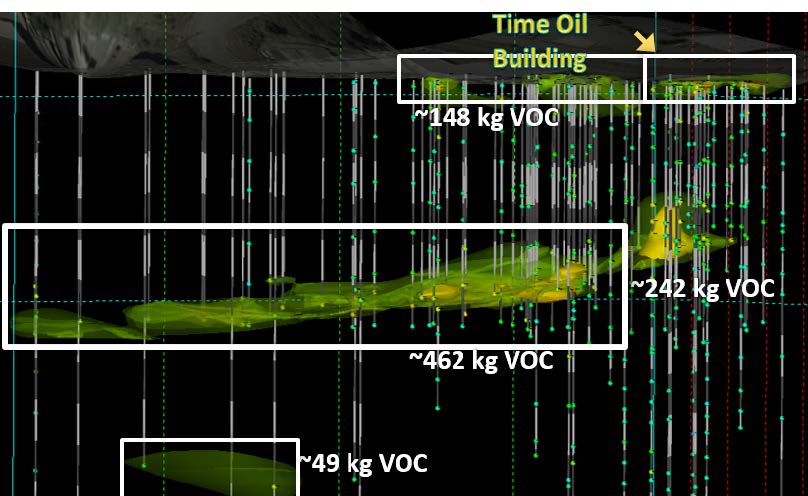

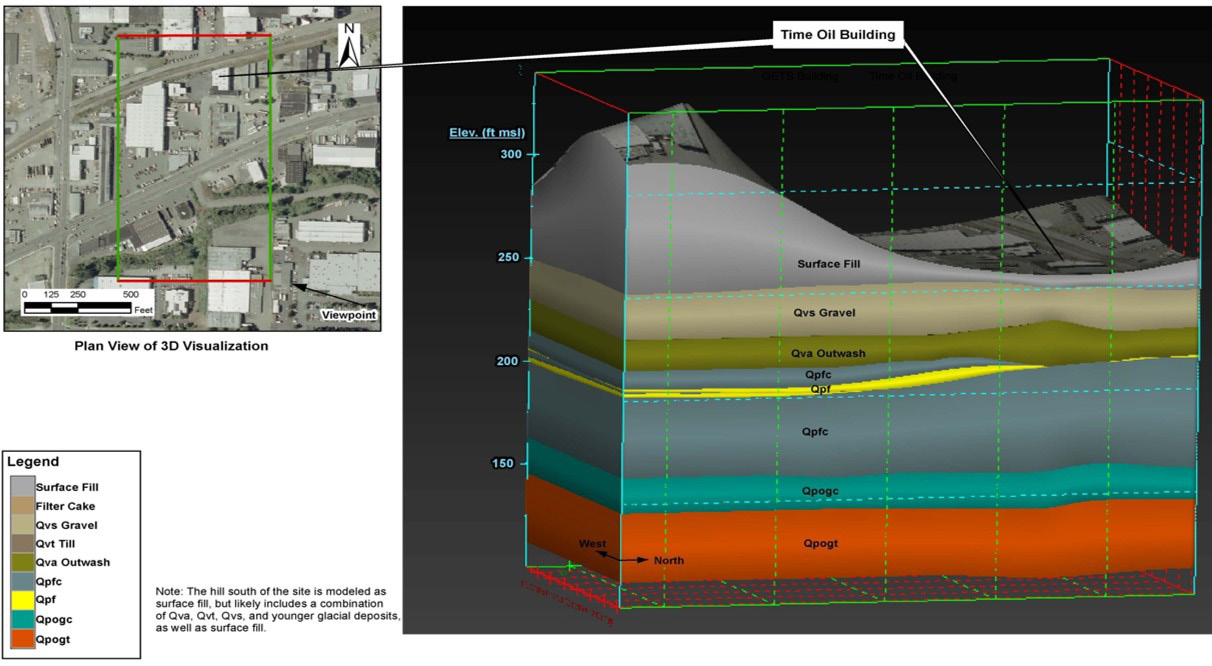

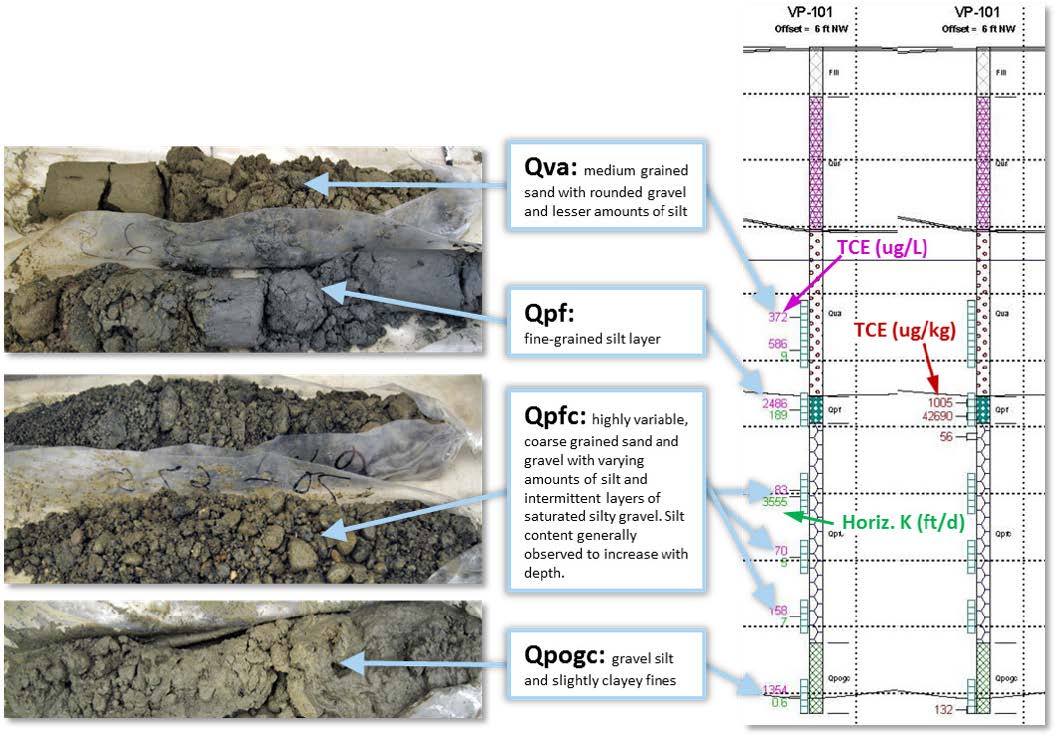

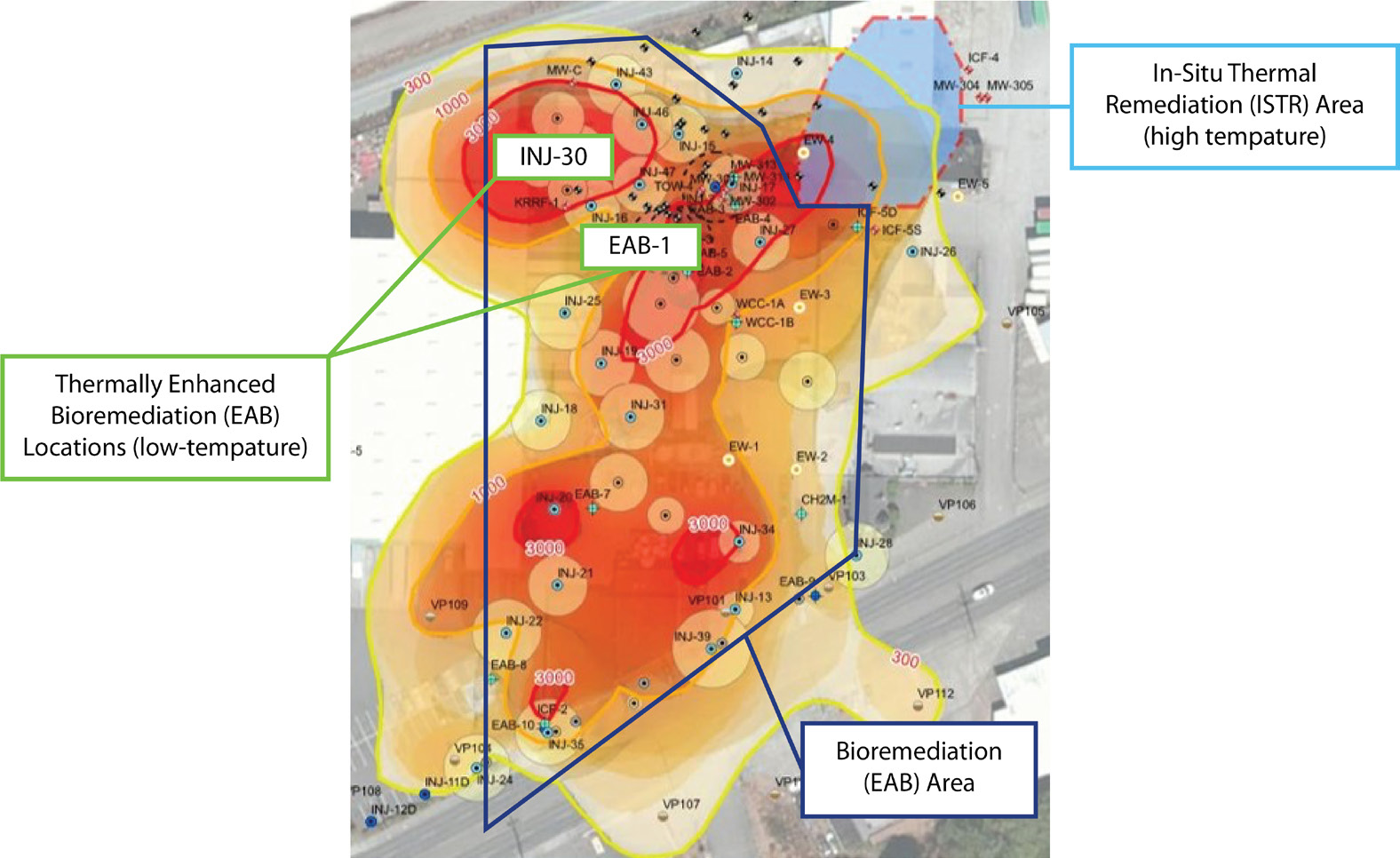

Honor Award - Environmental SustainabilityWell 12A Technical, Design, and Remediation SupportEntrant: CDM Smith Entrant Profile CDM Smith is a full-service engineering and construction firm providing lasting and integrated solutions in water, environment, transportation, energy, and facilities to public and private clients worldwide. The 2.5 square-mile Commencement Bay, South Tacoma Channel Superfund Site in Tacoma, WA is a designated remediation area consisting of three separate sites. This project focuses on one of those sites, Well 12A, which includes a former oil processing plant on mostly industrial and commercial land with some residential housing. The Environmental Protection Agency is the lead agency responsible for the site, with support from the Washington State Department of Ecology. The USACE Seattle District is implementing remedial actions on behalf of EPA. Despite 25 years of remedial action, a review of the existing remedy for the site concluded that it was inadequate to meet remedial goals of achieving groundwater restoration in a timeframe sufficient for the City of Tacoma's projected future water use. In 2009, EPA contracted CDM Smith to perform a feasibility study, which resulted in a new Record of Decision (ROD) amendment to address deficiencies in the original remediation approach. CDM Smith designed, implemented, and monitored performance of the multi- technology remedial action. The combined remedy included excavation, in-situ thermal remediation, in-situ bioremediation, and thermally enhanced bioremediation to augment the existing pump-and-treat, wellhead treatment, and soil vapor extraction remedial actions that had failed to achieve cleanup objectives. Kemron performed the excavation and Kemron and TRS Group, Inc. designed and implemented the electrical resistance heating component of the in situ thermal remediation. Project DescriptionFollowing nearly a half century of industrial manufacturing and waste oil recycling, cleanup of legacy contamination at the South Tacoma Channel Well 12A Superfund site has made dramatic progress. Designated as a hazardous waste site in the early 1980s, traditional efforts to remove harmful contaminants like trichloroethene (TCE) have given way to cutting-edge, and ultimately more effec- tive, strategies. Due to an innovative mix of treatment methods, the project team has accomplished ambitious cleanup targets approved by the Environmental Protection Agency (EPA) to allow transfer of management of the formerly toxic site back to the state of Washington. ComplexityProject site located in busy commercial and industrial district near public drinking water source. The 162,000 square-foot source area extended nearly 100 feet into a drinking water aquifer and extended nearly half a mile to a municipal supply extraction well, known as Well 12A. Projected water use needs by the City of Tacoma added a sense of urgency to make meaningful progress towards aquifer restora- tion at the already complex Superfund site. Following decades of traditional pump-and-treat-style remediation efforts with no end in sight, a more aggressive approach was needed. Site contained mix of dense nonaqueous phase liquids (DNAPLs). The presence of DNAPLs, one of the most challenging types of hazardous waste to characterize and clean up, created a challenging project environment. DNAPLs can sink in the aquifer, and "smear" over large vertical distances adsorbing onto soils, and their low solubility combined with low parts-per-billion cleanup standards results in contaminating large volumes of aquifer that can last for centuries. Coordination required between multiple public agencies. Though officially under the purview of EPA as an official Superfund site, Well 12A required additional collaboration between the United States Army Corps of Engineers (USACE), the State of Washington, and the City of Tacoma. Originality and InnovationA robust conceptual site model helped narrow the target area and save more than $1 million in treatment costs. A rigorous vertical profiling investigation along with three-dimensional (3D) visualization modeling of the data helped to pinpoint a discrete zone of DNAPL-impacted aquifer responsible for over 96 percent of contaminant discharge to the aquifer and significantly reduce the target treatment volume for remediation. First use of mass discharge reduction as a remediation metric. Deviating from traditionally-used maximum contaminant levels (MCLs) to achieve compliance, the project team decided to take an alternate path and use mass discharge reduction to accommodate the unique characteristics of the Well 12A site. This represented the first Record of Decision (ROD) for a Superfund site that included a goal to reduce mass discharge by 90% from the source area as a compliance metric. Innovative design of bioremediation amendments resulted in more targeted, successful treatment. By blending shear-thinning polymers with emulsified vegetable oil amendments, the project team opti- mized the bioremediation approach and improved amendment distribution in low-permeability zones that contained significant contaminant mass. The project team manufactured the blended amendment onsite, as it was not a commercially available product. This resulted in one injection event required to sustain treatment over 5 years post-injection. Project DescriptionIntegrated ApproachMost treatment technologies have a "sweet spot" where they can provide maximum contaminant mass removal within a certain geological locale. Due to the varied conditions at Well 12A, there was no single treatment method that would reach the 90% mass discharge reduction goal. Therefore, a combination of synergistic remedial technologies were employed:

QualityAmbitious goals combined with unique mix of innovative technology resulted in unmitigated success. The latest sampling results revealed that water flowing to the city's drinking wells is below the MCL for TCE and other contaminants. In total, TCE mass discharge was reduced by over 97 percent from the DNAPL source area. Effective treatment choices and efficient implementation resulted in accelerated timeline. After decades of steady but slow treatment of the contaminated site, remediation efforts conducted in the past five years met EPA goals and resulted in the upcoming turnover of the site back to the state of Washington. The Well 12A project team achieved the record of decision goals and made more progress in reducing the contaminant impacts to the drinking water aquifer than the previous 30 years of treatment. Social and Economic AdvancementThis project represents a significant investment in the restoration of the aquifer to its beneficial use as a drinking water source for the City of Tacoma. Post-remediation sampling and evaluations have demon- strated that the project has lowered contaminant mass discharge well below acceptable levels and that residual contaminants will attenuate to below MCLs prior to reaching Well 12A. Additionally, the project has set a precedent for the continued use of mass discharge as a measure of success. Incorporating mass discharge into a project ROD can lead to more efficient treatment combinations and ultimately a more cost-effective and streamlined remediation process. Click images to enlarge in separate window. Click here to return to the list of 2019 winners. |