- Home

- Contact Us

- News & Events

- Awards

- AAEES Awards Criteria

- 40 Under 40 Recognition Program

- Edward J.Cleary Award

- Excellence in Environmental Engineering and Science Education

- Gordon Maskew Fair Award

- Honorary Member

- International Honorary Member

- Ralph and Joe Bales Graber Science Award

- Stanley E. Kappe Award

- Environmental Communications Awards Competition

- Excellence in Environmental Engineering and Science Competition

- The AAEES Chapter Blue Marble Award

- Resources

- AAEES Microcredentials

- Annual Reports

- AAEES Press Releases

- AAEES Website How To VIdeos

- Environmental Engineer and Scientist

- Environmental Engineering Body of Knowledge

- PFAS Resources

- Specialty Examination Guide

- Students and Young Professionals Resources

- Who's Who in Environmental Engineering & Science®

- Leadership Opportunities

- Membership

- Donate

- Jobs

2019 Excellence in Environmental Engineering and Science® Awards Competition Winner

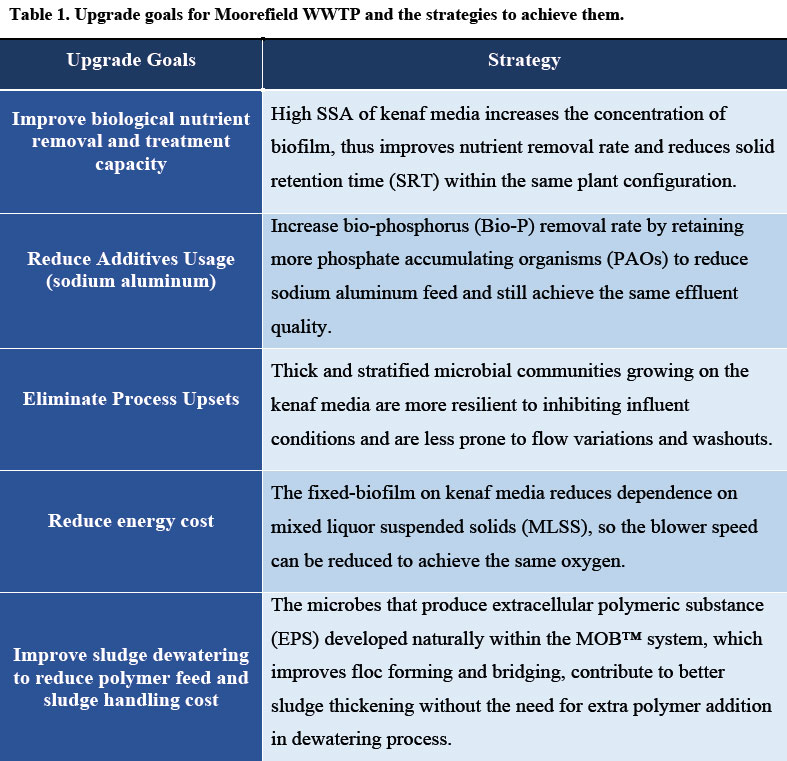

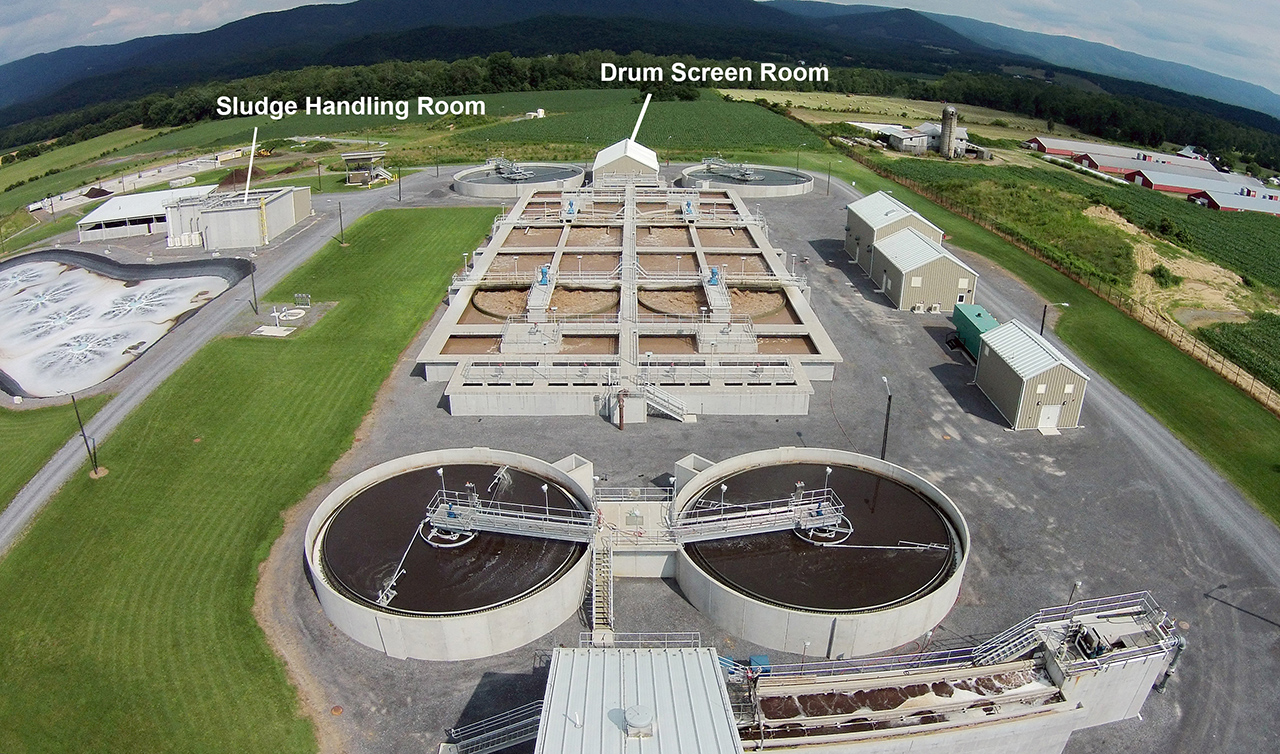

Grand Prize - Small FirmsTown of Moorefield/Hardy County Regional WWTP Upgrade with the MOB® ProcessEntrant: Nuvoda, LLC Entrant Profile Nuvoda, LLC is an environmental engineering company dedicated to innovative, sustainable and renewable wastewater technologies geared directly towards water reuse. Headquartered in Raleigh, NC with a R&D department located in Blacksburg, VA, Nuvoda's core competency lies in researching, developing, manufacturing, integrating and delivering industry leading, cutting-edge biofilm and granular technologies. From industrial to municipal, Nuvoda has clients throughout north America and has continued to solve the most pressing issues faced by modern wastewater treatment systems. The Moorefield/Hardy Regional WWTP was constructed in 2013 as an effort to preserve the Chesapeake Bay Watershed. The project was a collaboration between the town and poultry giant JBS Pilgrim's – a major local employer. However, because the WWTP receives 90% of its influent from the industrial process, the imbalanced nutrient and flow level often impacted the biological treatment performance and stressed operational cost. To help reduce operation cost, system upsets and improve treatment efficiency, Nuvoda engineers proposed a full upgrade in 2017 using the company's patented Mobile Organic Biofilm (MOB®) Process. Nuvoda provided the engineering design plans, oversaw the construction and manufactured the necessary components for the MOB® process. Crismon Construction was the contractor. The upgrade took 3 months to complete and was finished in March 2017. Project Description

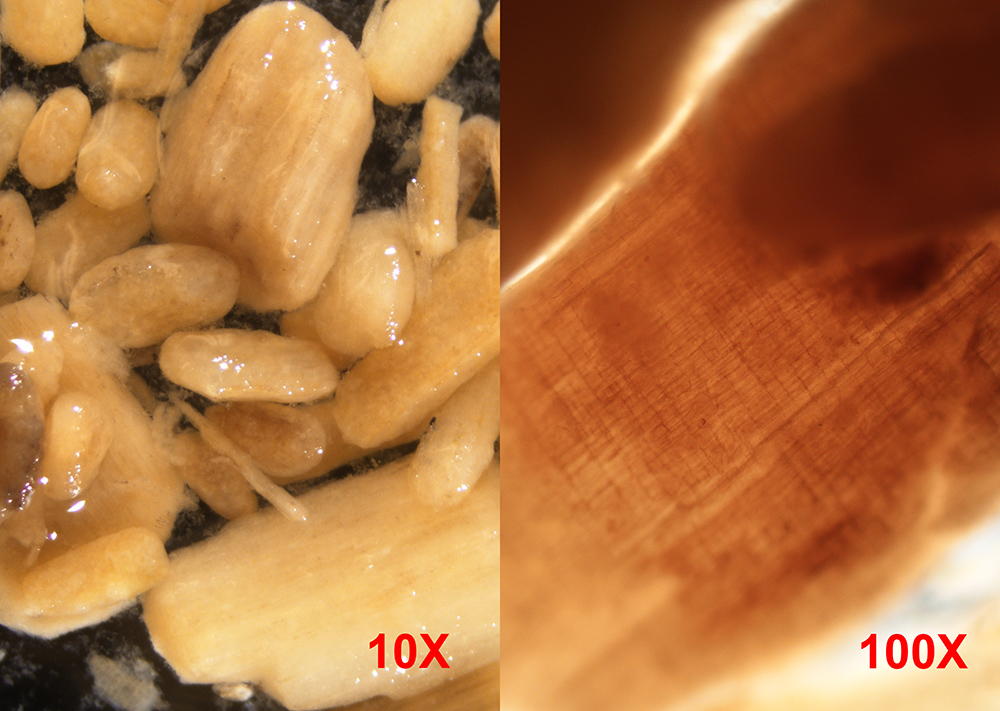

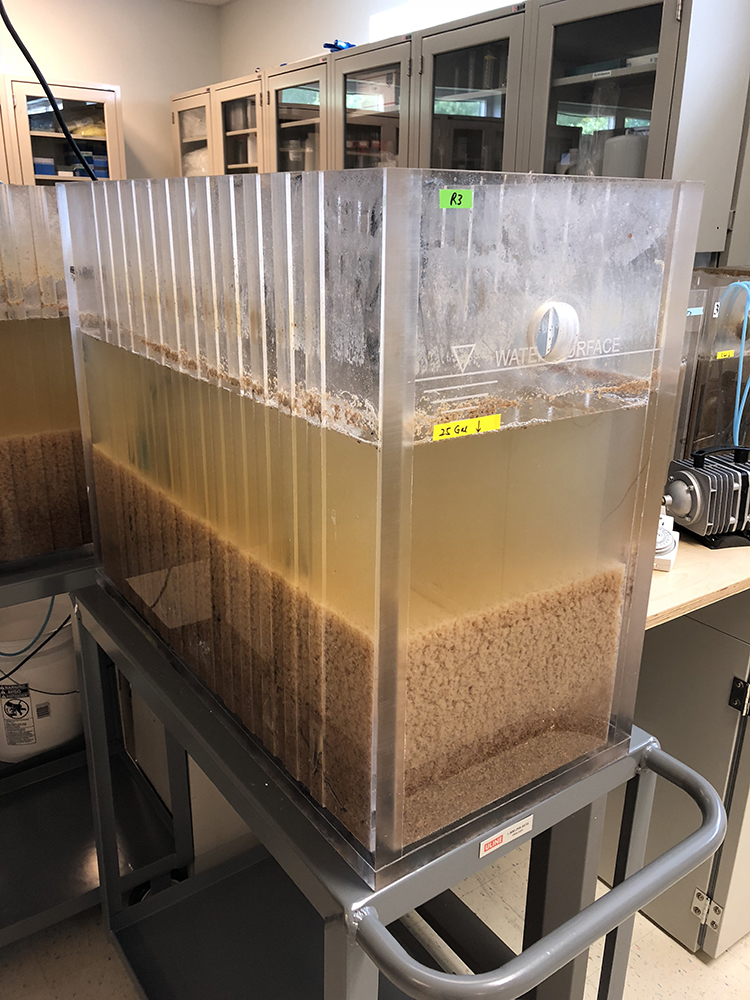

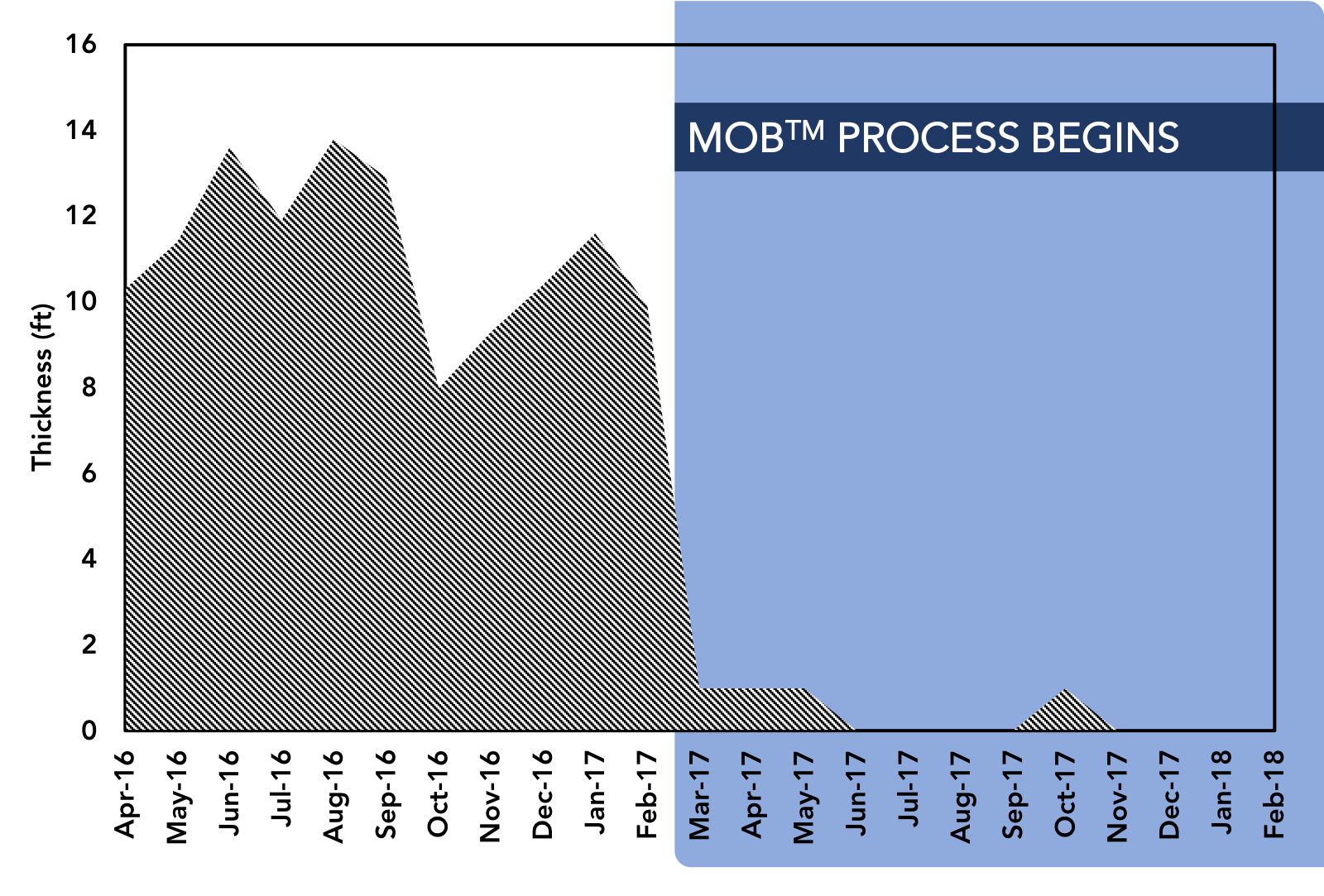

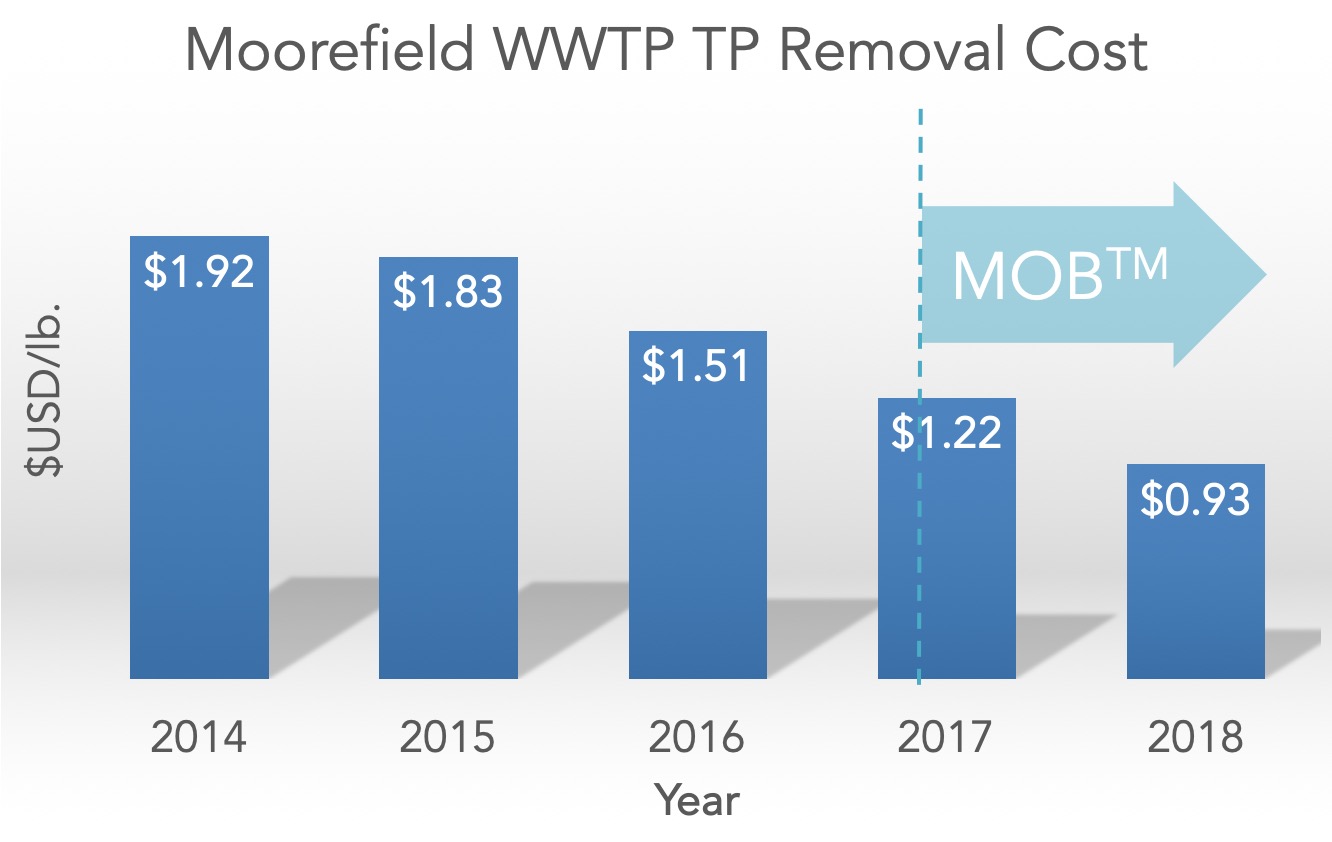

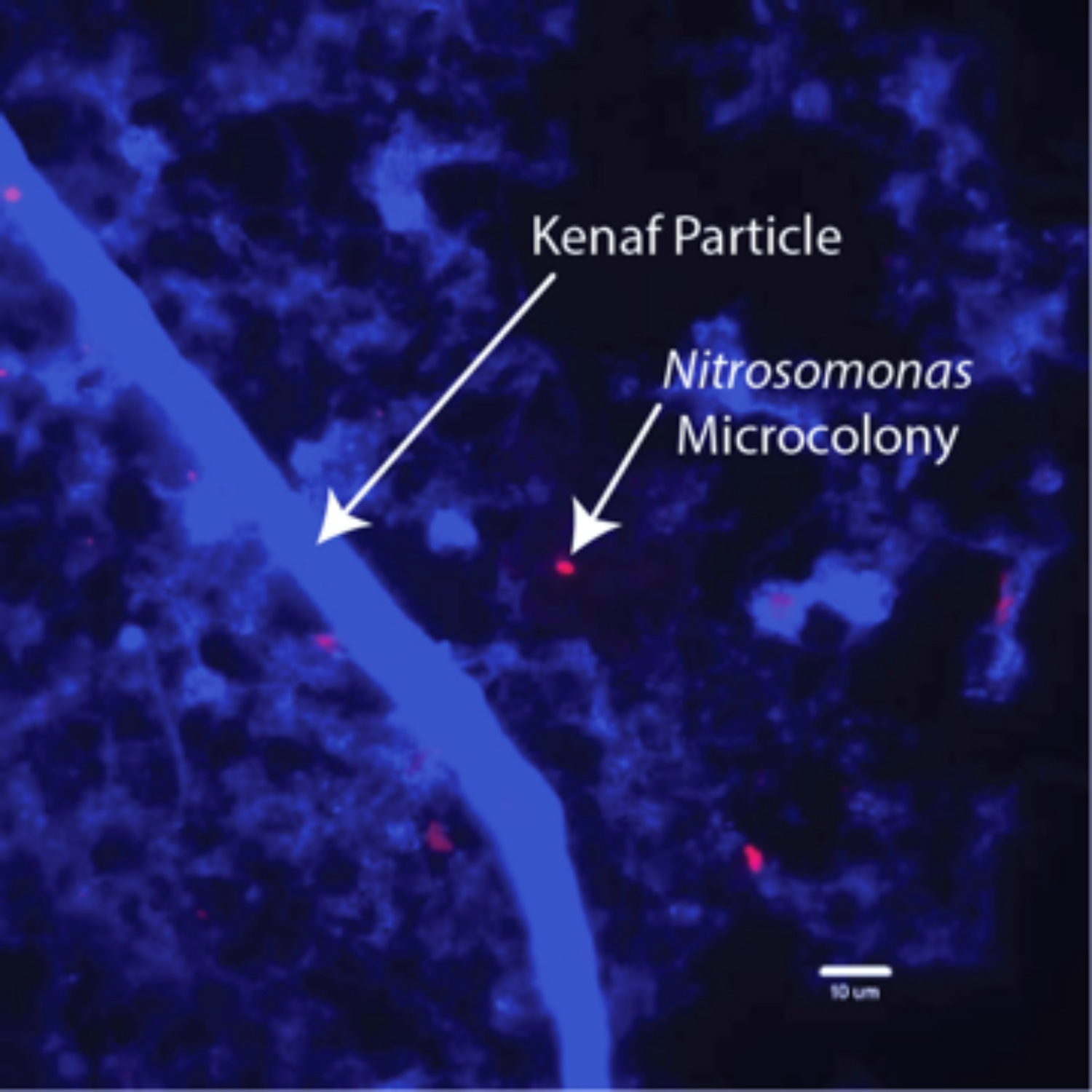

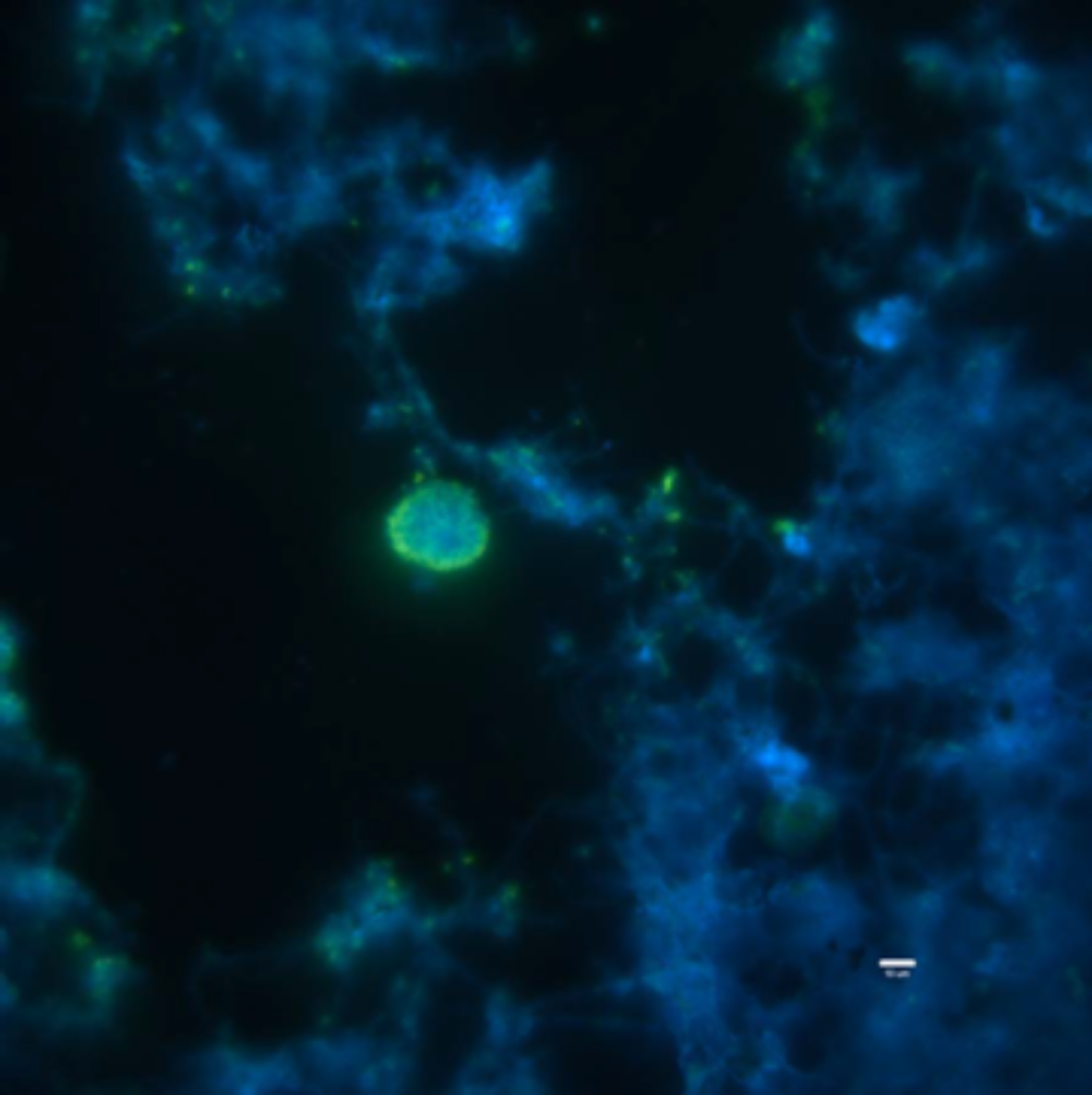

Moorefield/Hardy Regional WWTP ChallengesComplexityIn 2013, a partnership between the Town of Moorefield, West Virginia and a local JBS Pilgrim's poultry manufacturing facility resulted in the construction of the 4.1 MGD Advanced Nutrient Wastewater Treatment Plant (WWTP) to improve the region's discharge quality into the Chesapeake Bay Watershed. The treatment facility's state-of-the-art 5-stage Bardenpho biological treatment process handles 90% industrial and 10% municipal influent to meet the stringent discharge limits (total nitrogen, TN = 51,431 lb/yr; total phosphorus, TP = 5,221 lb/yr). However, soon after start-up, the Moorefield/Hardy WWTP encountered multiple issues caused by the waste flow from the poultry process. The industrial influent's high but variable nutrient levels and flow rate and lack of BOD have cost the WWTP an average of $13,000 a month in additives, and at least 4 major system upsets caused by sanitation chemicals in 2016, costing the WWTP $200,000 to recover. The MOB® Process UpgradeTo reduce operation cost, system upsets and improve treatment efficiency, Nuvoda proposed a full upgrade with the company's patented Mobile Organic Biofilm (MOB®) Process. Originality and InnovationThe MOB® process is an innovative and sustainable wastewater treatment process developed by Nuvoda to address stringent nutrient removal levels, settleability issues, and limitations of reactor footprint and configuration. The patented MOB® process utilizes kenaf core, a renewable lignocellulosic material harvested from the fast growing kenaf plant (Hibiscus cannabinus), as a substratum for fixed-film growth in biological nutrient removal (BNR) processes. The porous kenaf particles are machined to approximately 500 µm in size with estimated specific surface area (SSA) larger than 20,000 m-1 (K1 media SSA ~ 1,000 m-1). When compared to traditional activated sludge and fixed-film processes, the high SSA of kenaf media supports high concentration of biofilm growth, which significantly shortens SRT and minimizes occupation of reactor volume while achieving the same or higher level of nutrient removal rate. When the biofilm is fully developed, the kenaf media acts like granular sludge that harbors stratified microbial community for simultaneous BNR with high settleability, and is free to circulate into the secondary clarifiers to improve SVI. The "mobile" and granular-sludge-like property of kenaf media eliminates the need for extensive screen installation, reduces down time during upgrade, retrofits into almost any treatment plant configurations, and is a more time and cost effective alternative to the actual granular sludge systems. Integrated ProjectThe MOB® Process upgrade for the Moorefield/Hardy WWTP consisted of 60 ton of kenaf media added to the 4.1 MGD 5-stage bioreactor, a 300 GPM drum screen for kenaf media recycling, RAS lines, and a belt-press sludge dewatering system. The goal was not only to provide the highest performance system for the protection of the local aquatic environment, air quality (reducing odor) and soil health, but also consider the client's financial and down-time budget. Nuvoda was able to supply a high-performance treatment process with minimal modifications to the existing plant that took only 3 months to complete, and develop a waste disposal strategy for the client that help reduce sludge handling cost and landfill stress through efficient dewatering, or increase value of the waste through an upcycling composting plan. Click images to enlarge in separate window. Click here to return to the list of 2019 winners. |