2019 Excellence in Environmental Engineering and Science® Awards Competition Winner

Grand Prize - Environmental Sustainability

Nutley Site Remediation Project on Behalf of Hoffmann-La Roche

Entrant: TRC Environmental Corporation

Person in Charge: Rebecca Hollender, CPG, LSRP

Location: Nutley, New Jersey

Media Contact: Dawn Pompeo

Entrant Profile

TRC Environmental Corporation (TRC) is a global engineering, consulting and construction management firm with over 140 offices and 5,000 employees. A pioneer in engineering and scientific developments since the 1960s, TRC serves a broad range of public and private clients, implementing complex projects from concept to completion. TRC provides technology-enabled solutions to the environmental, infrastructure, power, and oil & gas markets. TRC is committed to sustainability in our business practices and when developing innovative solutions to meet client needs.

TRC has served as Hoffmann La-Roche's lead consultant for development and implementation of the strategies to remediate Roche's former 120-acre manufacturing and R&D facility in Nutley, New Jersey. Roche's goal was to mitigate all environmental risks including those related to non-Roche operations and expeditiously restore the Site to its full potential. Hundreds of TRC scientists, engineers, and specialists from across the country worked with Roche to develop a highly innovative, collaborative, sustainable, and programmatic approach to streamline and accelerate the Site investigation and cleanup. This comprehensive remediation program rapidly enabled the repurposing and redevelopment of the former Roche property, fostering the creation of new jobs, economic growth, and rekindled tax revenues, which benefit New Jersey and the surrounding communities.

A network of subcontractors contributed to the project's success, including TRS Group, Accelerated Remediation Technologies, Redox Tech, Cascade, Panther, Linde-Griffith, Northstar, Terra Systems, Peroxychem, Specialty Systems Integrators, Newterra, Ozone Solutions, Provectus Environmental, Westbay Instruments, FLUTe, ARM Geophysics, HRS Drilling, Salomone, GES, SGS-Accutest, TestAmerica, Pace, Microbial Insights, and many others.

Project Description

For more than 80 years, Roche Nutley was the healthcare company's US headquarters, furthering scientific and medical breakthroughs and contributing to the economic and social fabric of surrounding communities. Upon Site closure in 2013, Roche commissioned TRC to spearhead an innovative, collaborative and environmentally sustainable remediation plan for the 120-acre property consistent with Roche's guiding principles. The goal was to accelerate remediation, meet or exceed New Jersey's stringent standards (i.e., protect human health and the environment) including pre- and non-Roche impacts, and enable rapid redevelopment of the Site.

The Site is underlain by a complex multi-unit, aquifer system with regional faults, intricate groundwater flow regimes, and geochemically reactive zones. Nearly 200 areas of concern were identified. Key concerns were chlorinated volatile organic compounds (CVOCs), petroleum hydrocarbons, 1,4-dioxane, and historic fill impacts. The Site is traversed by municipal sewer systems that conveyed non-Roche sanitary and industrial sewage. Breaches in these sewers resulted in CVOC releases including non-aqueous phase liquids (NAPL). Groundwater impacts due to off-Site sources and sewers extended hundreds of feet into bedrock.

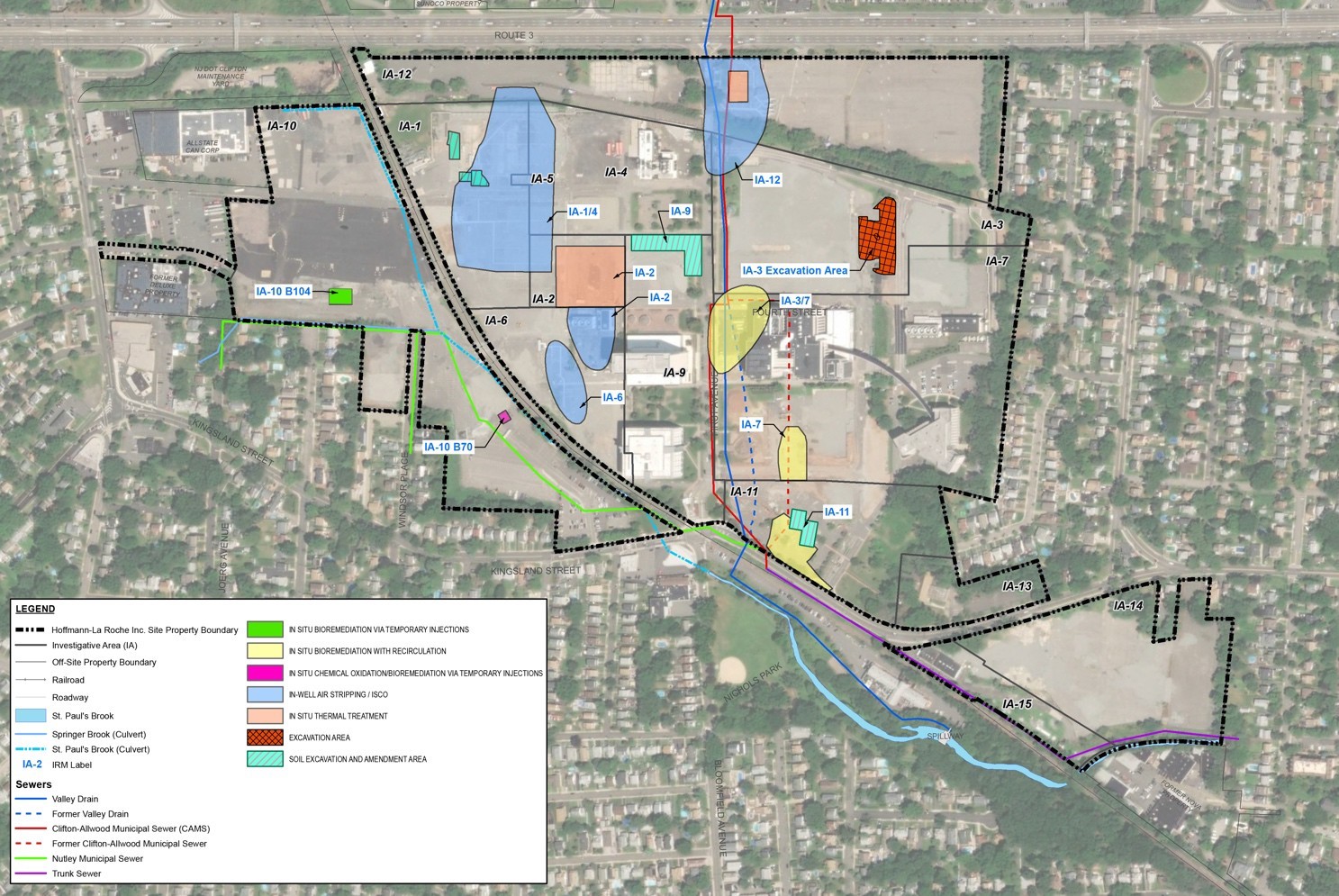

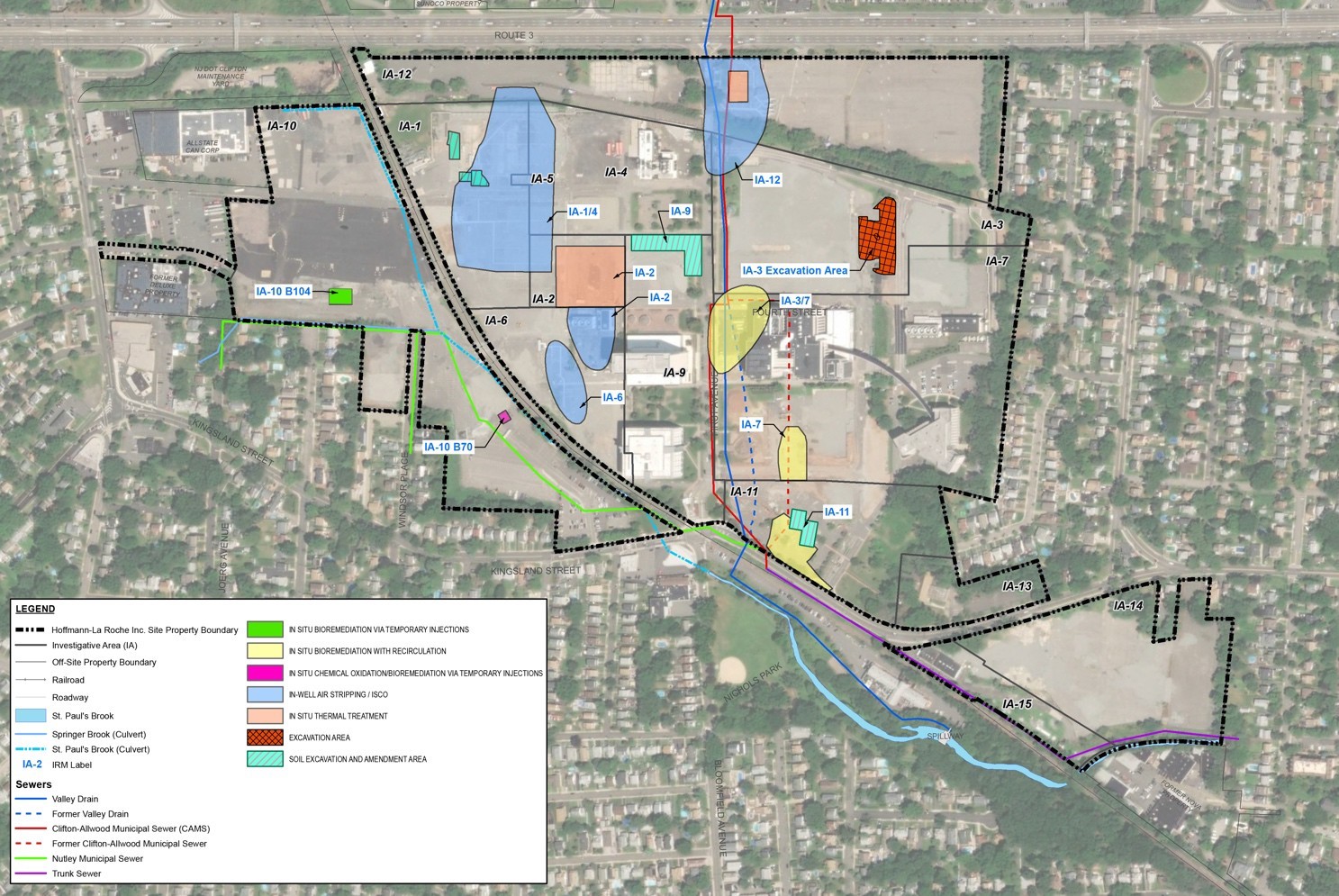

To achieve Roche's goals, meet regulatory and redevelopment requirements and timeframes, and address technical and logistical challenges, TRC developed a multi- pronged strategy with novel approaches and innovative technologies including a Remediation Road Map that streamlined the remediation process by dividing the Site into 15 Investigative Areas (IAs) and assigning seven NJ-Licensed Site Remediation Professionals (LSRPs) to the 15 IAs.

Communication, procurement, and resource management and plans were developed to ensure efficient program management; quality, timely communications and decision-making; and tracking the progress of numerous remedial and construction activities. TRC oversaw the operation of over 30 drill rigs, management of thousands of tons of soil, and installation of miles of piping and several remedial systems.

TRC fast-tracked remedial investigations (RIs) via a TRIAD-like method with minimal mobilization/demobilization rounds and addressed uncertainties and regulatory inquiries during pre-design investigations (PDIs). The comprehensive RI included a robust analytical database for approximately:

- 19,800 soil samples from >9,000 soil borings;

- Thousands of groundwater samples from >1,100 wells (up to 700-foot depth);

- Hundreds of surface water and sediment samples; and

- Hundreds of air samples for vapor intrusion assessment.

TRC prepared Soil Remedial Action Workplans consistent with Roche's goal to remediate to NJDEP's most stringent soil remediation standards without capping or deed restrictions.

To minimize soil remediation volumes and environmental footprint, the following novel actions were conducted:

- For the first time at this scale in New Jersey, spatially-weighted compliance averaging was employed to limit soil removal.

- An obsolete rail line near the Site was reactivated to transport contaminated soil off-site, significantly minimizing truck traffic impact on the community (saving >4,000 trips), using 180,000 fewer gallons of fuel, and emitting 2,000 fewer tons of greenhouse gases.

- Approximately 30% of slightly impacted soil was beneficially reused as landfill cover; the rest was transferred to regulated waste management facilities.

- A 700-foot stretch of St. Paul's Brook Riparian Area was remediated and stabilized using extensive erosion controls, removal of invasive plants and reintroduction of native vegetation.

TRC prepared and NJDEP approved all 15 Soil Remedial Action Reports within an unprecedented three-year timeframe, allowing the Site to be quickly divested and repurposed, shaving years off the traditional remediation process, and leading to greater environmental, economic and social benefits for the community.

Likewise, TRC and Roche proactively addressed sources of groundwater contamination by accelerating the implementation of 10 interim remedial measures (IRMs) employing innovative and sustainable approaches, including:

- Proactive PDIs: Upon source identification, TRC completed PDIs and pilot tests to define IRM extents and options. Innovative techniques included mobile data solutions, multiport piezometers, advanced geophysical logging, compound-specific isotope analysis, microbial/molecular evaluations, direct-sensing probing, discrete fracture network/matrix- diffusion evaluation, magnetic susceptibility and methane inhibition.

- Pioneering IRMs: IRMs were developed following a robust feasibility analysis and environmental footprint assessment. Combinations of technologies and flexible designs were implemented to overcome uncertainties due to complex subsurface conditions, commingling chemical plumes, matrix diffusion limitations and evolving redevelopment plans.

- Cutting-edge in situ thermal treatment in bedrock, powered by Roche's on-Site cogeneration facility, to remediate NAPL and high-concentration zones saved years of treatment time, prevented contaminant spreading, and removed >2,700 pounds of VOCs.

- ART in-well air stripping (IWAS) combined with in situ chemical oxidation (ISCO) or enhanced in-situ bioremediation (EISB) was used to remove VOCs from bedrock. These innovative combinations improved the amendment distribution and radius of influence, enhanced IRM effectiveness, and greatly reduced operational duration and energy consumption. ART-IWAS and ISCO using ozone or persulfate were combined for the first time to address CVOCs and 1,4-dioxane in bedrock. On-site ozone generators eliminated hundreds of truckloads of liquid oxidants. Anaerobic EISB with modified ART-IWAS or in-situ chemical reduction enhanced the remediation of recalcitrant CVOC impacts. Most IRMs incorporated vapor extraction to prevent adverse emissions.

- To address a NAPL CVOC release into bedrock from a breach in the municipal sewer, high-resolution, multi-media sampling results were incorporated into a 3- dimensional visual model to minimize the IRM footprint. The 1,200' x 27' excavation of bedrock was completed near a building where a unique structural support system reduced excavation/backfill volumes by 50%. Backfill including bioamendments created a passive, long-term, reactive zone to destroy lingering contaminants.

The soil and groundwater remedies saved >1.3 Billion BTUs of total energy and >7,000 tons of CO2 emissions compared to alternative remedies and emphasized water preservation and waste minimization via in-situ remedies, recirculation and discharge within the watershed.

Despite the complex Site conditions, the pro-active implementation of aggressive IRMs resulted in significant reductions of both plume extents and concentrations to achieve the groundwater IRM remedial goals in nearly all areas within unprecedented timeframes of one to three years, resulting in the July 2018 opening of Hackensack Meridian School of Medicine at Seton Hall University. Related redevelopment will provide key education, research and career opportunities for generations to come. TRC's holistic, innovative, programmatic, and collaborative approach accelerated the remediation process, and enabled rapid economic redevelopment, creating jobs, rekindling tax revenues and benefitting the surrounding communities.

Click images to enlarge in separate window.

|

|

|

In 2012, Roche retained TRC to perform the investigation and remediation of soil and groundwater at the 120-acre Hoffmann-LaRoche Nutley facility. To effectively conduct the complex remediation, numerous innovative strategies were employed, such as dividing the Site into 15 investigative areas (IAs) for concurrent and tailored investigation/remediation and implementing 10 interim remedial measures (IRMs) for groundwater, several of which were pioneering combination approaches. As a result of this aggressive remediation approach, TRC estimates that the normal investigation and remediation timeframe were reduced by several years while achieving a high level of effectiveness and safety, which was critical to the rapid repurposing of the Site.

|

As part of its comprehensive Remedial Investigation (RI), TRC employed principles from the Triad approach to the investigative efforts incorporating systematic project planning, dynamic work strategies, and real-time or near real-time measurement techniques. Embracing this approach allowed for efficient and effective use of resources, reduction in mobilizations, highly-informed decision making for all stakeholders, and accelerating timeframes. A robust set of soil, groundwater, and sediment/surface water data was compiled, including: approximately 19,800 soil samples from more than 9,000 soil boring locations; more than 400 surface water and 70 sediment samples; and installation of more than 1,100 monitoring wells in overburden and bedrock, with more than 300 wells installed in bedrock to depths greater than 100 feet below surface (as well as approximately 400 temporary well points used to situate the monitoring wells in optimal locations). This picture presents a driller from Ameridrill Inc., one of approximately 30 drilling companies employed during the project, advancing a boring for rock core sampling in IA-6. The hole created by this boring was later converted to a monitoring well used to collect groundwater samples.

|

|

|

|

Following the groundwater RI, TRC employed innovative investigative, analytical and treatability techniques during pre-design investigations (PDIs) including mobile data solutions, multiport piezometers, advanced geophysical logging, compound-specific isotope analysis, microbial/molecular evaluations, direct-sensing probing, discrete fracture network (DFN)/matrix-diffusion evaluations, magnetic susceptibility, and methane inhibition. This photograph shows a groundwater pumping test and tracer study that was performed as part of the PDI work in IA-11 to improve hydrogeological and geochemical understanding of the complex, subsurface environment. Underneath the near tent is the well from which water is extracted. Data are transmitted from transducers placed in neighboring wells with various depths, located beneath the orange buckets, and recorded on data loggers on tables underneath the tents.

|

The Site was remediated to NJDEP's most stringent soil remediation standards wherever possible, thereby making most of the Site appropriate for unrestricted use, as opposed to using NJDEP's presumptive remedy of "capping" contaminated soils. The absence of extensive caps and deed restrictions was critical to the future unrestricted use and rapid repurposing of the property. Approximately 240,000 tons of impacted soil, most of which contained contaminants attributable to the presence of historic fill material preceding Roche's tenure on the Site. Approximately 30% of contaminated soil was beneficially reused, i.e., recycled, as daily landfill cover. This photograph shows remedial excavation at the former Building 73 in IA-9. Soils impacted with polycyclic aromatic hydrocarbons (PAHs), polychlorinated biphenyls (PCBs), benzene, lead, and tetrachloroethene (PCE) and its breakdown products were removed during remediation. Over 500 tons of asphalt was recycled as part of the Building 73 excavation. In total, over 11,000 tons of asphalt were recycled during the Site-wide soil remedial action.

As part of the soil RA, extensive health and safety planning was completed and implemented throughout the construction. A comprehensive air monitoring program ensured that the work did not create any air quality issues for the workers and surrounding community.

|

|

|

|

An on-site rail car terminal was constructed to utilize an adjacent reactivated rail line that transported contaminated soils for off-Site disposal. The rail line, with intermodal containers loaded with impacted soils and covered in black tarps, can be seen running up the right side of the photograph. Additional loaded intermodals, staged to be placed on the rail cars, can be seen dispersed throughout the area. The use of rail significantly reduced truck traffic (an estimated 4,000 trips) and minimized impact on the community. Moving freight by rail is four times more fuel efficient than highway transport; trains move a ton of freight over 480 miles on a single gallon of fuel, and emitting fewer greenhouse gases than comparable truck transport. In our project, rail transport used 180,000 fewer gallons of fuel and emitted 4.1 million fewer pounds of greenhouse gases than transportation by truck. In addition to increasing our capacity to ship off-Site and shorten our project time frame, train transport reduced the potential for accidental spill, soil dispersal and air hazards.

|

Between 2013 and 2017, approximately 8.25 million gallons of contaminated groundwater pumped from monitoring wells, IRM wells and excavations were containerized in numerous 21,000-gallon Fractionation (Frac) tanks. The containerized groundwater was treated on-site using sedimentation and carbon filtration, which eliminated an estimated 2,500 trips to the disposal facility via truck. On-site treatment was purposely selected for energy efficiency to allow for the extracted water to be discharged to the POTW within the watershed, instead of being trucked to an off-site disposal facility. The main treatment area, consisting of red-painted Frac tanks with a total capacity of over half a million gallons of water and two sediment and granular activated carbon treatment trains, can be seen at the top of the photograph.

Additional Frac tanks are staged throughout the area to allow for additional capacity. At the bottom left of the photograph, the IA-2 In situ Thermal Treatment (ISTT) interim Remedial Measure (IRM) can be seen.

|

|

|

|

TRC designed and oversaw the stabilization and restoration of native vegetation within the degraded riparian area of a 700-foot reach of St. Paul's Brook along the southern property boundary adjacent to Nichols Park. The remedial action included the removal of approximately 1,600 tons of material (i.e., abandoned sewer line, historic fill, debris, etc.) and invasive plants; placement of clean soils; and the installation of extensive erosion controls and native species. Additionally, a deed notice was established to prevent future disturbance or development. In addition to preventing erosion of bank soils and fill to the brook, the restored landscape provides much improved native habitat. As part of the restoration, 58 native trees were planted, including river birch, pin oak, black willows, shagbark hickory, tulip, white pine, and white oaks. In addition, over 50 pounds per acre of perennial grass and wildflower seeds were placed in the area. The photograph on the left shows the condition of Saint Paul's Brook in the winter of 2013. The ruins of an abandoned sanitary sewer and concrete debris is seen throughout the area. The photo on the right shows St. Paul's brook in December 2018, almost two years after the restoration was completed. Native species can be seen growing along the restored riparian area.

|

|

|

To proactively remediate groundwater contamination, even though no ecological or human impacts were found, TRC recommended and Roche approved of the implementation of an unprecedented number of interim remedial measures (IRMs). The application of innovative technologies employed as IRMs helped Roche meet their aggressive timelines and has resulted in the destruction or removal of a very significant amount of contaminants found in Site groundwater, including several chlorinated solvent plumes resulting from a leaking municipal sewer line (never used by Roche) that traversed the Site, as well as the emerging contaminant 1,4-dioxane. Under traditional clean-up approaches, groundwater remediation would not have started until a Groundwater RAWP was submitted and approved by NJDEP. This graphic shows the location and type of IRMs employed throughout the site.

|

|

|

|

In IA-12, the IRM consisted of ISTT in Operable Unit-1 (OU-1) and IWAS, combined with in situ chemical oxidation (ISCO) using ozone and persulfate injections in OU-2. Electrical resistance heating (ERH) was selected as the ISTT technology to use at IA-2 and IA-12. Although energy- intensive for a short duration, ISTT was ultimately more energy-efficient than the alternative remedies. The alternatives likely would have required decades to hundreds of years to remediate the equivalent amount of contaminant mass in this complex geological setting. ERH heating uses electricity supplied to a densely spaced series of electrodes in the sub-surface to heat the groundwater to above 100 degrees Celsius and volatilize organic compounds for capture and treatment in the gaseous phase. In the photograph above, one can see a typical ERH setup including the network of vertical electrodes, as well as the power cords and vapor extraction piping. The combined IRMs were conducted to address elevated concentrations of chlorinated volatile organic compounds (CVOCs) coming on-site from an off-site source, the Clifton-Allwood Municipal Sewer (CAMS). The CAMS, which traverses the Site from north to south, has carried both sanitary and industrial wastewater (but not including any wastewater from Roche). The IA-12 IRM reduced CVOCs by an average of 92%, and approximately 1,143 pounds of VOCs were removed from the sub-surface.

|

In IA-1/4, TRC utilized IWAS combined with in situ chemical oxidation (ISCO) using ozone and persulfate injections in fractured bedrock to address 1,4-dioxane (an emerging contaminant) to depths of 90 feet. The innovative use of groundwater recirculation provided by the IWAS improves distribution and radius of influence of the injected oxidant, enhancing the rate and overall effectiveness of the ISCO treatment. Using ozone for in-situ oxidation of 1,4-dioxane in bedrock appears to be the first application of its kind in New Jersey. The system design and operational controls ensured that any unconsumed ozone was captured to prevent release to the atmosphere. This photograph shows a typical example of ozone injection and vacuum extraction piping.

|

|

|

|

TRC used enhanced in situ bioremediation (EISB) with recirculation to address VOCs in groundwater for the IA-3/7 IRM. This is another innovative strategy that employed multiple technologies to treat recalcitrant contaminants in a complex geologic setting. The IRM reduced the total CVOC concentrations in groundwater at all monitoring points within the target IRM treatment area, with overall reductions ranging from 76 to 100%. Individual target CVOC trends showed clear evidence of reductive dechlorination, with initial conversion of parent compounds (PCE and TCE) to daughter products (cis1,2-DCE and VC), followed by complete degradation of these daughter compounds. A methane inhibition additive was incorporated into the amendment injections, for the first time at this scale, following an extensive treatability study to optimize its effectiveness to minimize the amount of methane produced as a by-product of the EISB process. The IA-3/7 treatment area can be seen within the red fencing at the lower center of the photograph. The building at the center of the photograph is the new Hackensack Meridian School of Medicine at Seton Hall University. Since the school was opened during the implementation of the IRM, TRC installed the IRM infrastructure below the surface. The area was then paved to allow for roadways and parking.

|

In IA-11, TRC performed a source zone excavation IRM of overburden and bedrock impacted by Non-Aqueous Phase Liquids (chlorinated ethenes) from a breach in the municipal sewer. In the foreground of this panoramic view of the preliminary stages of the excavation, H-beam soldier piles were installed in a prescriptive manner along the outer excavation edge to depths of 33 ft. below grade and were cement-grouted into the bedrock. The precise placement of the H-beams was determined using a 3-dimensional visualization model that incorporated a robust dataset from high- density, multi-media sampling, inclusive of the discrete-fracture network approach. The geotechnical and structural design utilized the H-beams, a slide-rail system and structural braces to allow deep excavation (27 ft. below grade) near an existing building while minimizing dewatering and excavation volumes (estimated 50% reduction in volume versus traditional bench and slope excavation). In the background, the soldier pile-installation rig (Linde-Griffith) is demobilizing and 21,000-gallon fractionation tanks are being staged for the dewatering effort.

|

|

|

|

Down-hole view of the IA-11 IRM excavation footprint (addressing breaches in a municipal sewer not used by Roche) with slide-rail and structural brace system in place. The difficult matrix of undulating fractured and weathered bedrock is visible at the bottom where jack-hammering was required to break up and then excavate the impacted materials. Alternative remedies would have had technical limitations and likely would have been ineffective due to the complexity of the geology and the distribution of the NAPL-like concentrations (i.e., long durations or much more energy intensive). As the excavation advanced at depth, continuous dewatering was required to maintain an inward gradient (i.e., to prevent the loss of contamination freed up by the excavation activities) and to manage the influx of contaminated groundwater. Greater than 800,000 gallons of groundwater were pumped and managed during winter weather conditions with extended around-the-clock operations to shorten the excavation duration. All extracted groundwater was stored, treated and either returned to the excavation or discharged to the POTW within the watershed. Approximately 2,400 tons of impacted materials were excavated and disposed of off-Site (a reduction of approximately 50% compared to traditional bench and slope excavation methods).

|

View of the construction of the engineered backfill system in the IA-11 IRM excavation that incorporated high-permeability crushed stone mixed with bioremediation amendment and bio-nutrients. These amendments created a highly bioreactive zone to treat any lingering contamination in-situ. The field crew (Panther Technologies of Cascade) is laying a geotextile filter fabric to separate the amended backfill from the unamended backfill and to prevent silting or clogging of the bioreactive zone. Additional measures included an infiltration gallery and gas recovery system for future use if additional amendments or off-gassing required management.

|

|

|

|

Communication Outreach and Extensive Media Engagement

TRC and Roche implemented a comprehensive Public Notification and Outreach Plan to ensure communication and transparency regarding the Site remediation. This far-reaching communications program exceeds both State and Federal outreach and notification requirements. Efforts have included:

- Direct Mail

- Community Meetings

- Newspaper Ads

- Environmental Investigation/Remediation Website

- Telephone Hotline

- Signs

|

For more than 80 years, Roche-Nutley has been steeped in a history of sustainability and social responsibility that were integral to the company's business of discovering, developing, marketing and producing life-saving medicines.

TRC's novel approach to cleaning up the property after the Site closure and close collaboration with Roche and the NJDEP facilitated the rapid divestment and current redevelopment into a next- generation multi-tenant campus now known as ON3 (depicted in the graphic above) that carries forward its spirit of innovation. Besides the Hackensack Meridian School of Medicine at Seton Hall University (a Health complex that also houses the University's Graduate College of Nursing, School of Health and Medical Sciences and Multiple Myeloma Institute), the Site also now hosts a National Health Institute-designated Clinical Research Center and other best-in-class tenants that include Modern Meadow, Quest Diagnostics and the Ralph Lauren Corporation.

The Site remediation played a key role in allowing the property's repurposing, which is vital to the region's economic development. The redevelopment is bringing competitive jobs back to the area and will generate millions of dollars in tax revenue to support vital community services, such as education, emergency services and infrastructure in Clifton and Nutley.

|

|